Pressing-opening-type car trailer hook cover

An open type, trailer hook technology, applied in the field of auto parts, can solve the problems of inability to open, the trailer hook cover is stuck, waste, etc., and achieves the effects of easy assembly and opening, reliable connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

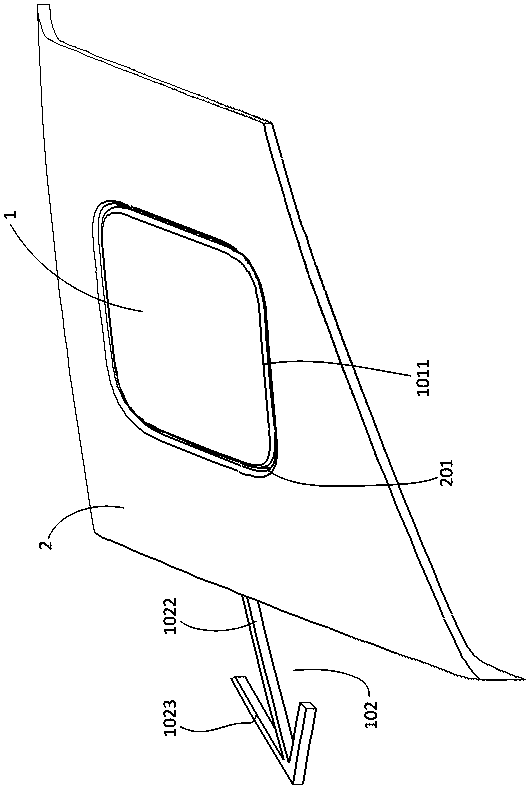

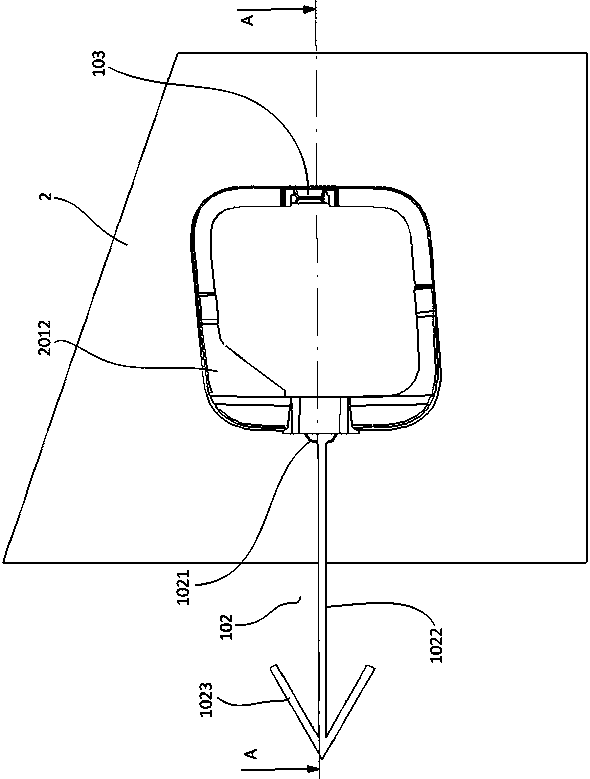

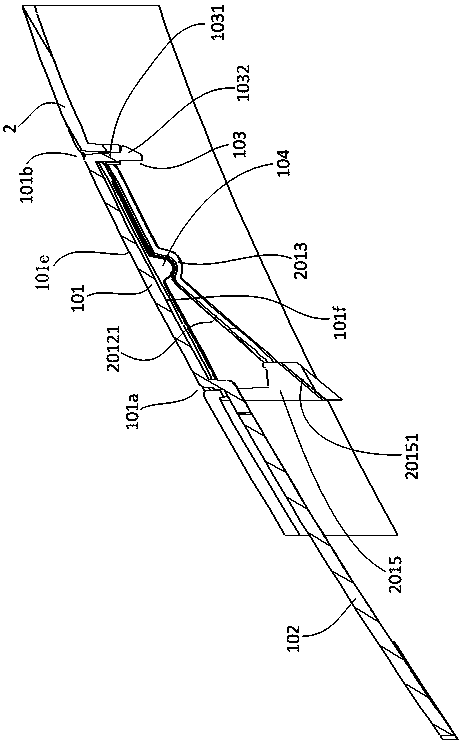

[0032] Please refer to Figure 1 to Figure 11 , the embodiment of the present invention presses to open the car tow hook cover, which includes a tow hook cover 1, and the tow hook cover 1 includes a cover body 101, and the cover body 101 has a first side 101a and a second side oppositely arranged 101b, and the opposite third side 101c and fourth side 101d, the first side 101a of the cover body is provided with a hook 102, the second side 101b is provided with a buckle 103, the third side of the cover body 101c and the fourth side 101d are symmetrically provided with a rotating shaft 104, and the rotating shaft 104 is disposed biased toward the buckle 103;

[0033] and

[0034] A connecting hole 201 opened on the bumper 2 and matched with the tow hitch cover 1, the connecting hole 201 has a hole wall 2011 extending toward the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com