High voltage bushing end screen grounding protective cover and high voltage bushing end screen

A technology of high-voltage bushing and protective cover, which is applied in the field of high-voltage equipment insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

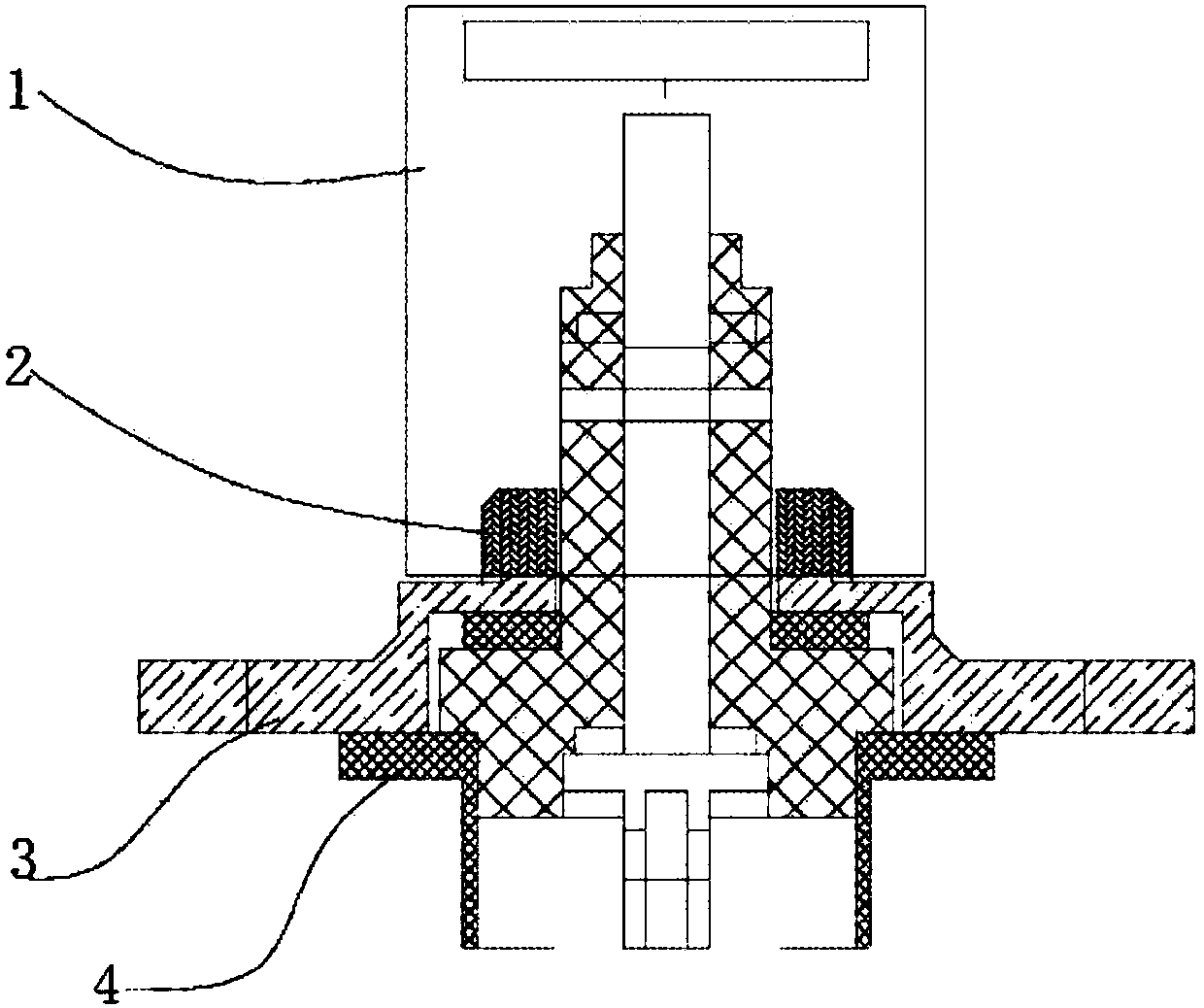

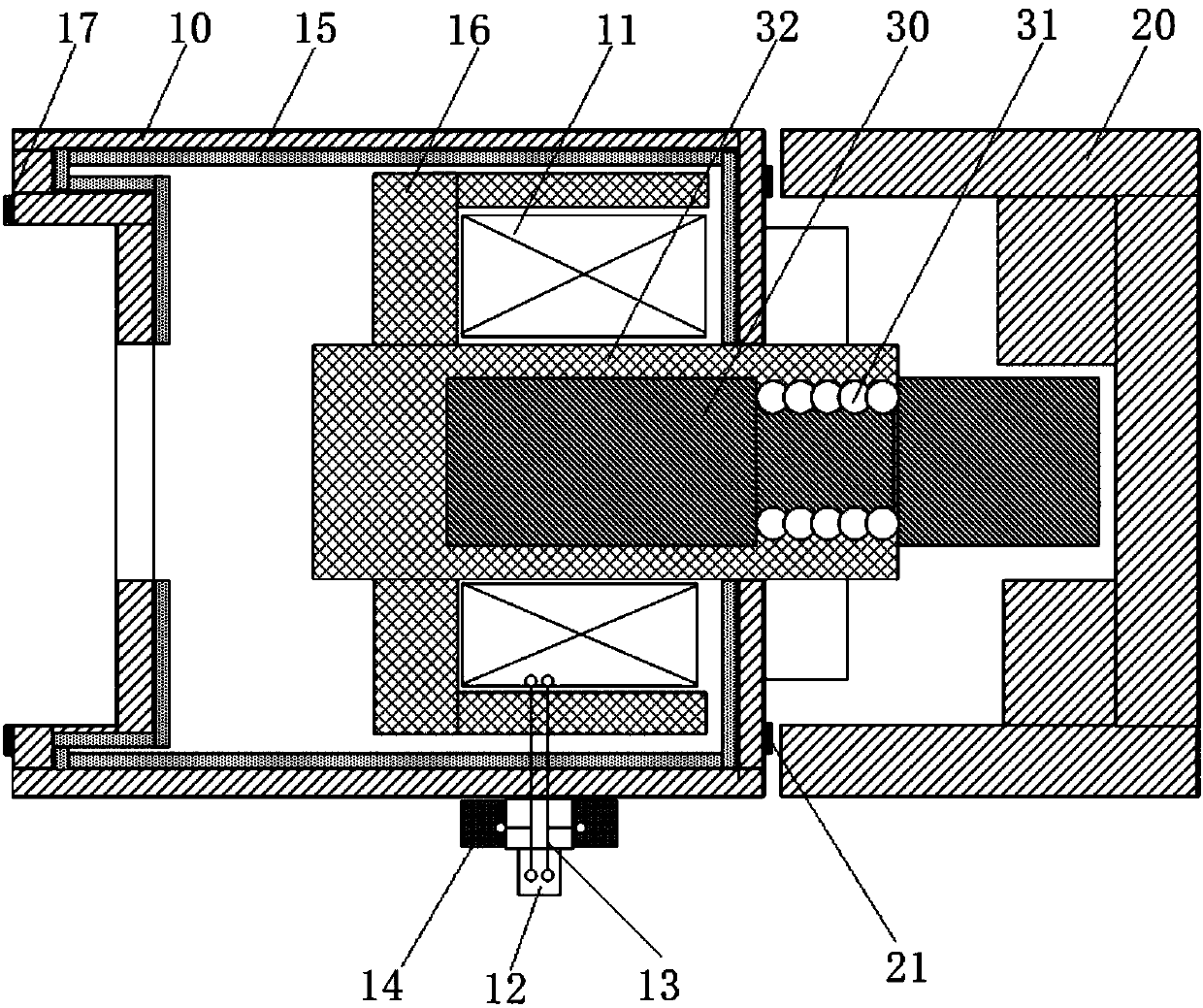

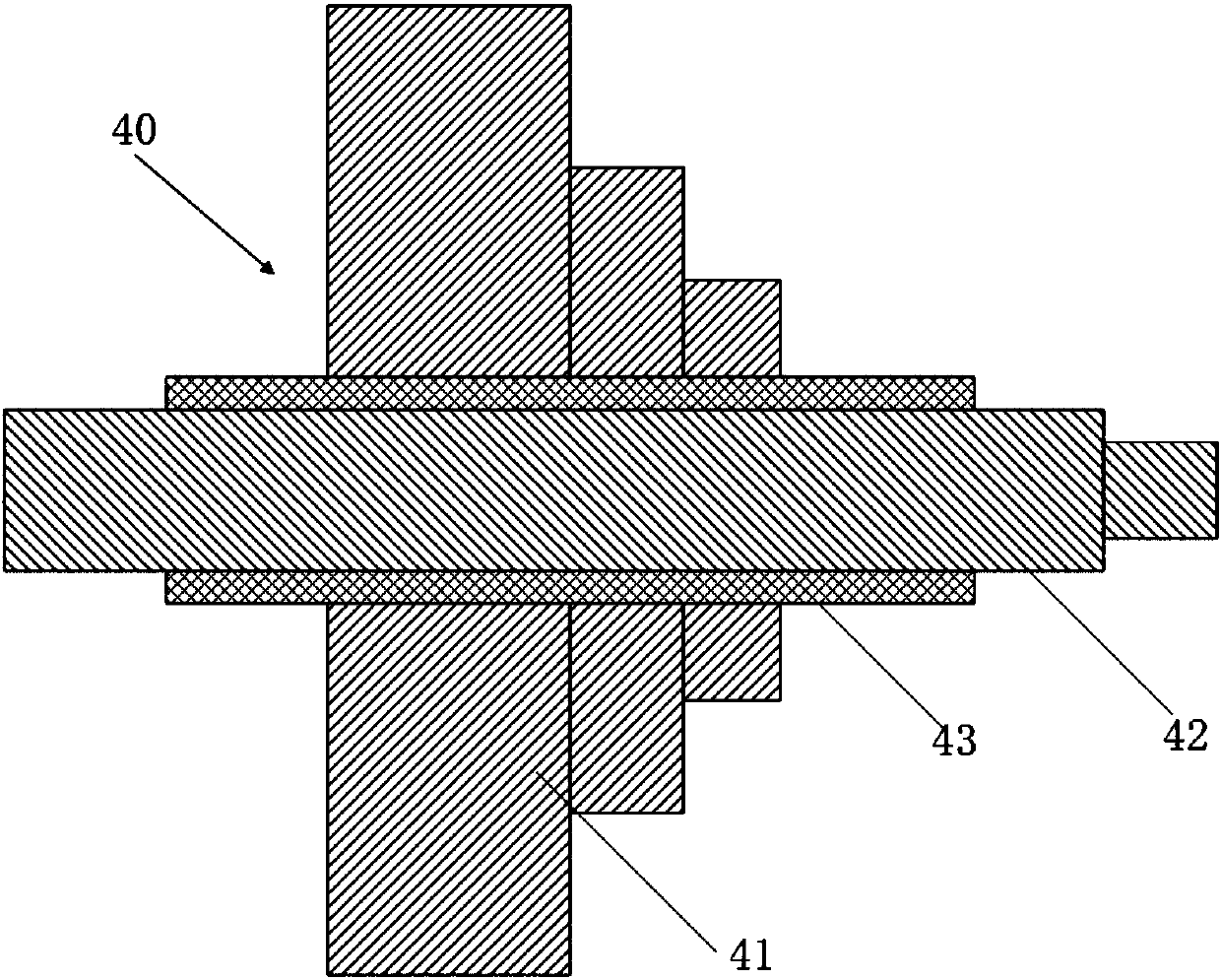

[0025] Such as figure 2 and image 3 as well as Figure 4 As shown, this embodiment provides a high voltage bushing end screen grounding shield, which is installed on the high voltage bushing end screen 40. The high voltage bushing end screen 40 includes a bushing end screen seat 41 and a The end screen lead 42 on the screen base 41, the grounding shield includes the grounding shield inner cover 10 connected to the end screen base 41 of the bushing, and the grounding shield outer cover 20 connected to the grounding shield inner cover 10 And the last screen lead extension rod 30 connected with the last screen lead 42, wherein the last screen lead extension rod 30 passes through the ground shield inner cover 10 and is connected with the ground shield outer cover 20, and the ground shield A measuring coil 11 is installed between the inner wall of the inner cover 10 of the cover and the extension rod 30 of the end screen lead wire, and a measuring line plug connector 12 is inst...

Embodiment 2

[0032] This embodiment provides a high-voltage bushing end shield, including a bushing end shield seat 41, an end shield lead wire 42 located on the bushing end shield seat 41, and the high-voltage bushing end shield grounding protection described in Embodiment 1. cover. Since the end screen of the high-voltage bushing includes the grounding shield described in the first embodiment, all the advantages of the first embodiment are also shared by the second embodiment. In addition, the outer wall of the end screen lead 42 is covered with an end screen lead insulation sleeve 43, through the effect of insulation, the end screen seat 41 of the bushing is a grounding body, which is beneficial to the end screen 40 of the high voltage bushing. Reliable grounding.

[0033] In summary, the technical solution of the present invention has the following advantages:

[0034] 1. The high-voltage bushing end screen grounding protective cover of the present invention is installed on the high-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap