Earth wire connector

A connection device and ground wire technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of cable shaking, low tensile strength, metal fatigue, etc., to achieve safe and reliable use, avoid stress, and eliminate tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

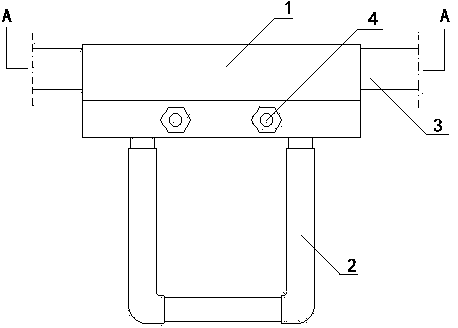

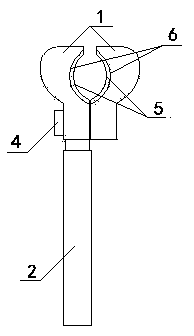

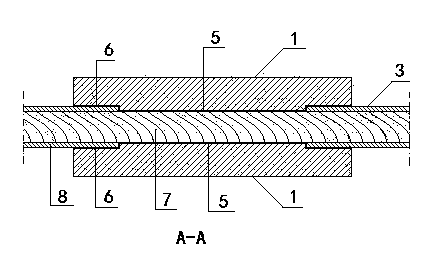

[0010] Such as figure 1 , 2 , 3 shows: the clamp body 1 and the ground wire hanging ring 2 connected together by the present invention are connected by two semicircular splints, and the two semicircular splints of the clamp body can pass the fastening bolts after clamping the cable 3 4 fastened and buckled into one, thus the present invention can be installed on the cable. The two ends of the inner wall of the clamp body are in the shape of steps, and the middle part is a boss 5, so its aperture is smaller than the apertures of the two ends 6. The aperture in the middle of the clamp body can be closely matched with the exposed wire core of the cable, and the apertures at both ends of the clamp body can be insulated from the cable. set to match.

[0011] When installing the present invention, the cable insulation sleeve is first stripped off. The stripped length should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com