Conical locking type strain clamp convenient for maintenance

A tension clamp, tapered technology, applied in the field of tapered locking tension clamp, can solve the problems of strain clamp breakage, lower power supply reliability, increased resistance, etc., to achieve structural stability and reduce power supply The effect of reliability, easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

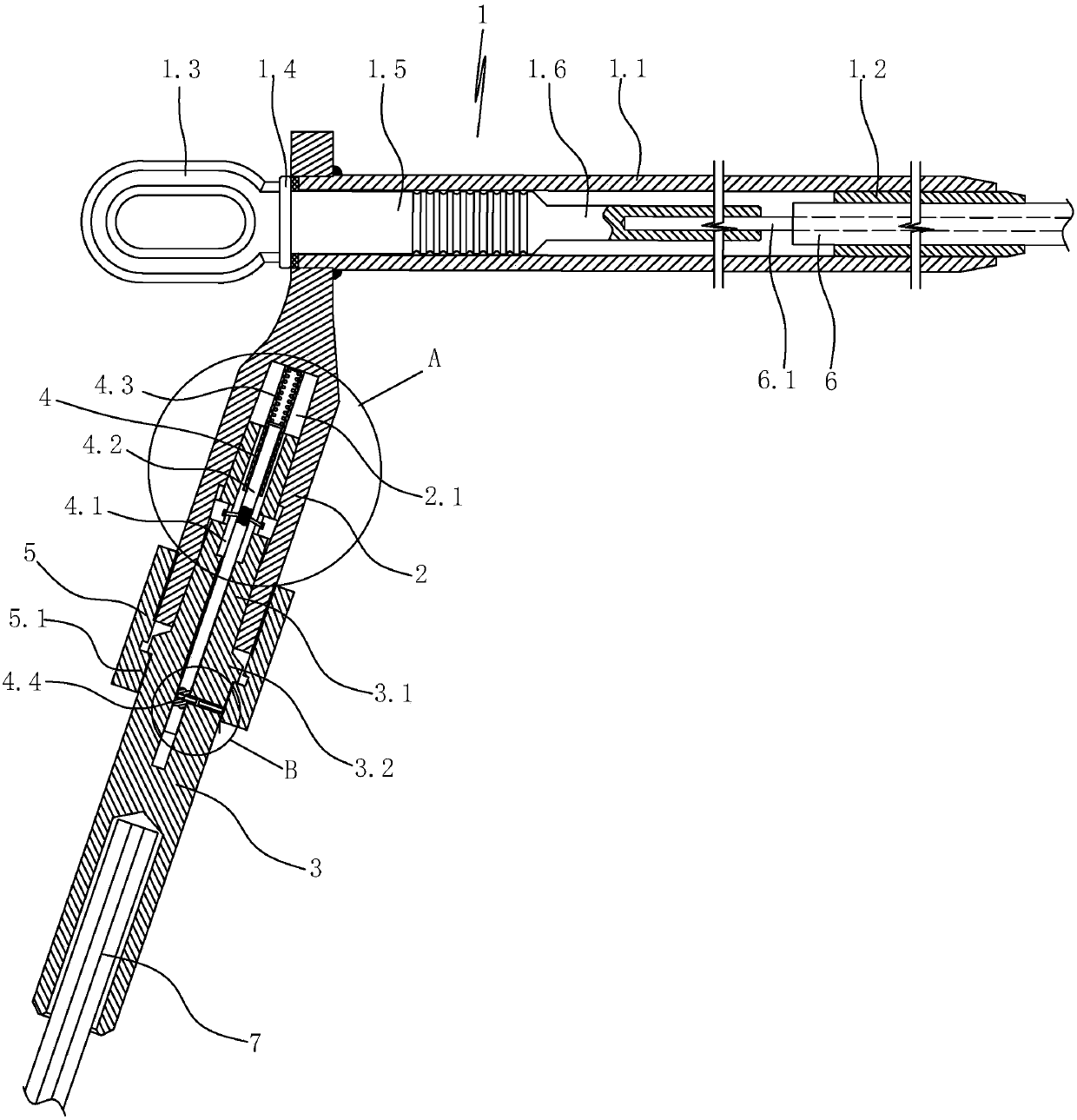

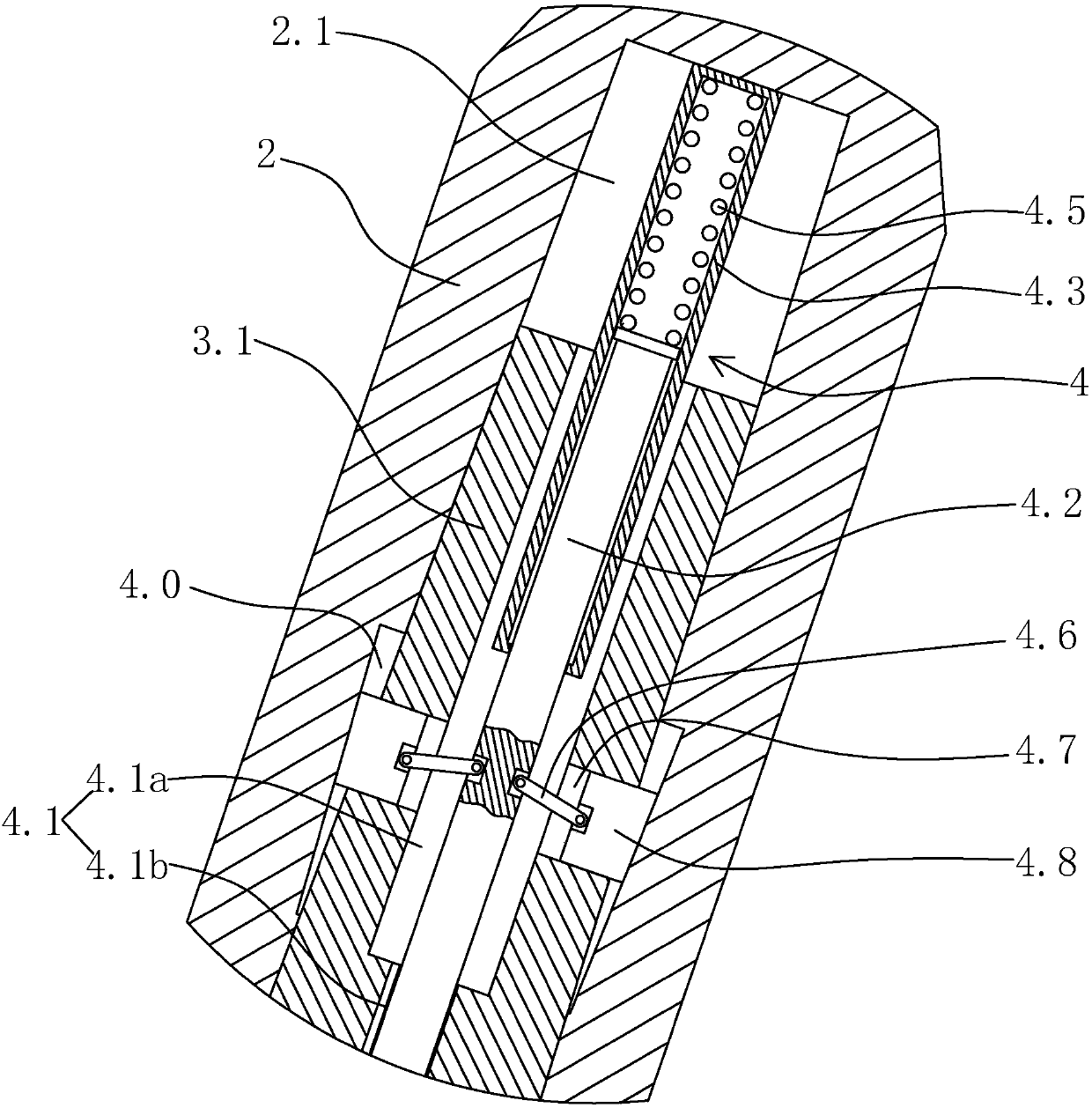

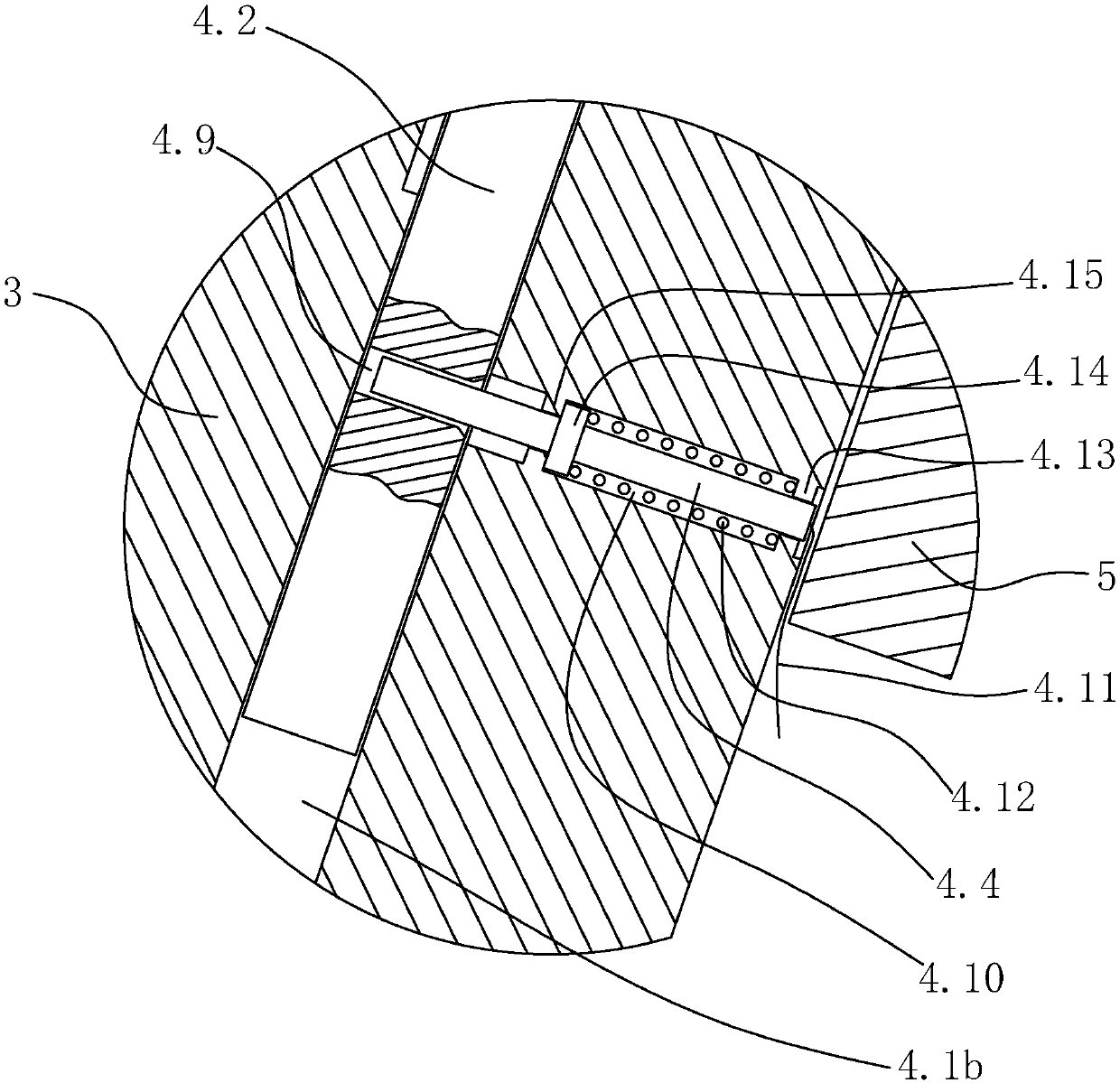

[0029] Such as figure 1 As shown in FIG. 1 , an easy-to-maintain tapered locking tension clamp includes a clamp body 1 and a drainage body. The clamp body is connected to the wire 6 . The upper part of the drainage body is connected with the clamp body, and the lower part of the drainage body is connected with the jumper 7 .

[0030] The clamp body includes an outer connection liner 1.1, a steel anchor and an inner connection liner 1.2. The steel anchor includes pull rings 1.3, liner connecting columns 1.5 and steel core connecting columns 1.6 distributed in sequence. A limit baffle 1.4 is arranged between the pull ring and the connecting column of the liner. The liner connecting column and the steel core connecting column are inserted into the outer connecting liner from the rear end of the outer connecting liner, and the limit baffle is ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com