Manipulator capable of realizing slant clamping and lifting and lowering

A technology of manipulators and clamping mechanisms, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of inability to lift, lift, and palletizing and clamping, and achieve simple structure and wide application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

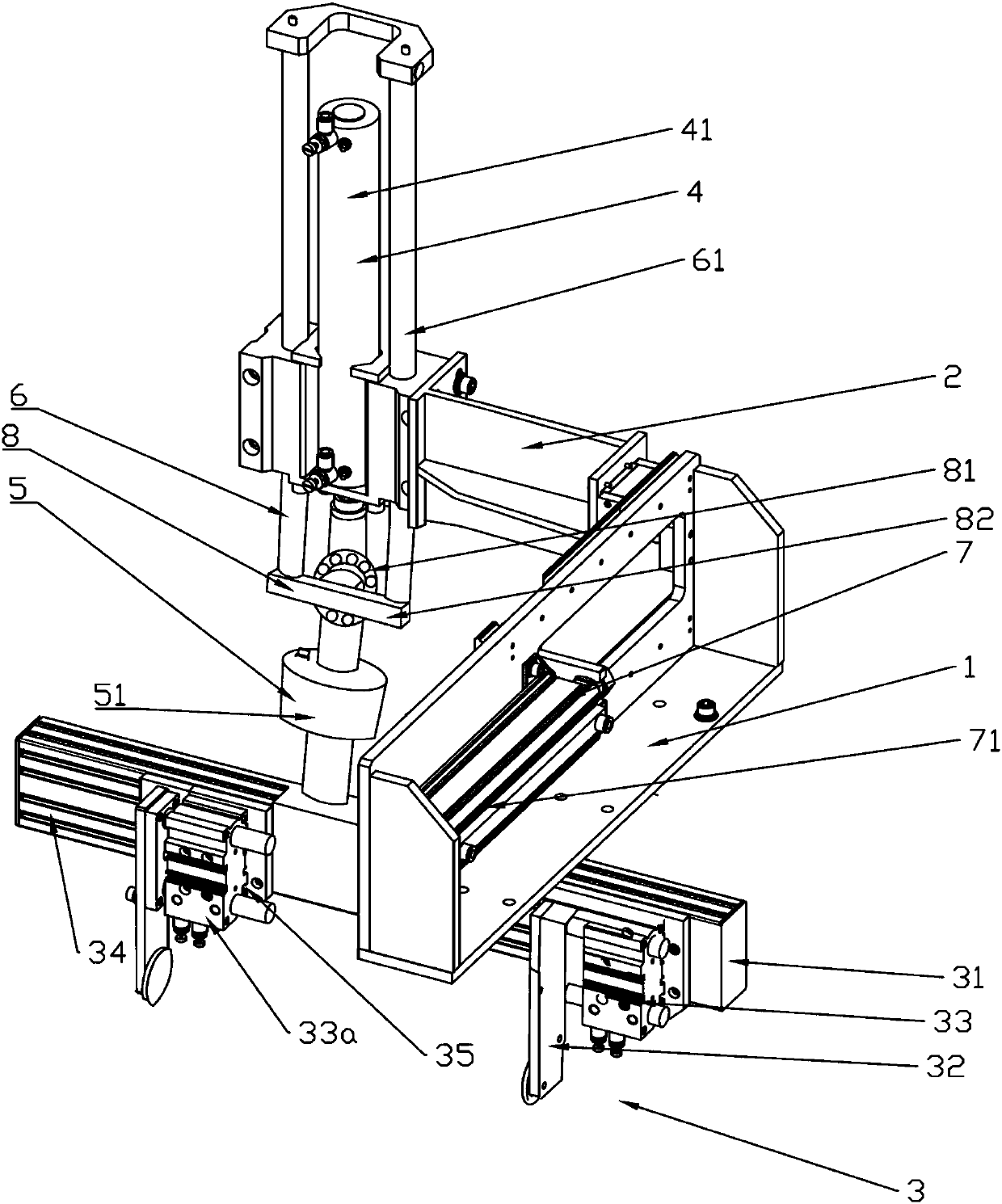

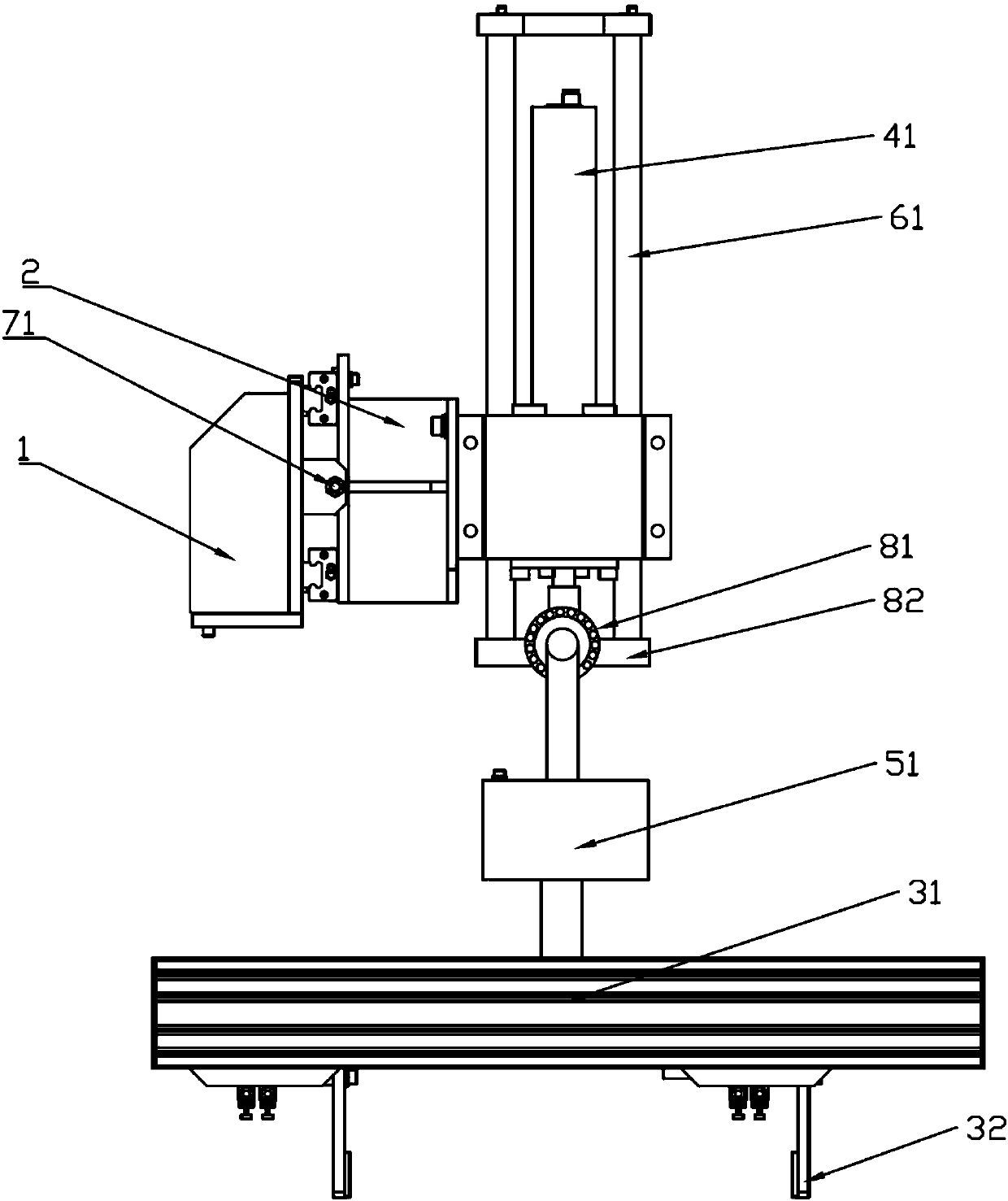

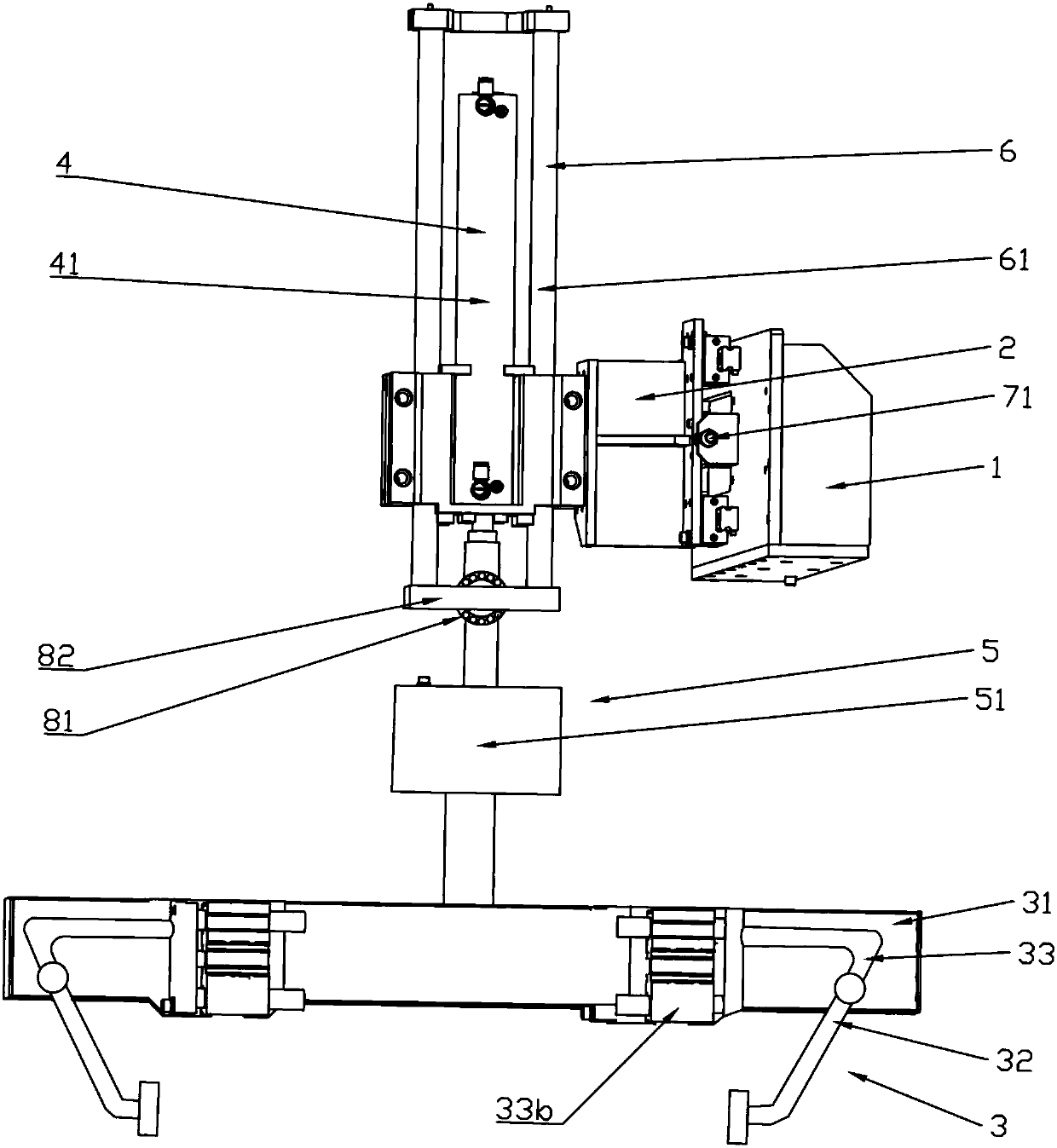

[0016] according to figure 1 as well as figure 2 The shown manipulator capable of oblique clamping and lifting includes a support frame 1, a fixed frame 2 slidingly connected with the support frame 1, a clamping mechanism 3 capable of clamping workpieces, and a lifting mechanism 4 for lifting the clamping mechanism 3 , the rotating mechanism 5 for rotating the clamping mechanism 3 , the tilting mechanism 6 for tilting the clamping mechanism 3 , and the moving mechanism 7 for horizontally moving the clamping mechanism 3 .

[0017] The clamping mechanism 3 includes a guide frame 31, two grippers 32 that are arranged on the guide frame 31 and can move, and a gripper driving mechanism 33 that drives the grippers 32. When the gripper driving mechanism 33 acts, the two gripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com