Erecting method for chamfered setting steel formwork

A technology for shaping steel and steel formwork, which is used in water conservancy projects, artificial islands, underwater structures, etc. It can solve the problems of excessively large formwork joints at the chamfered corners and insufficient rigidity of the formwork at the chamfered corners. Skilled and good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

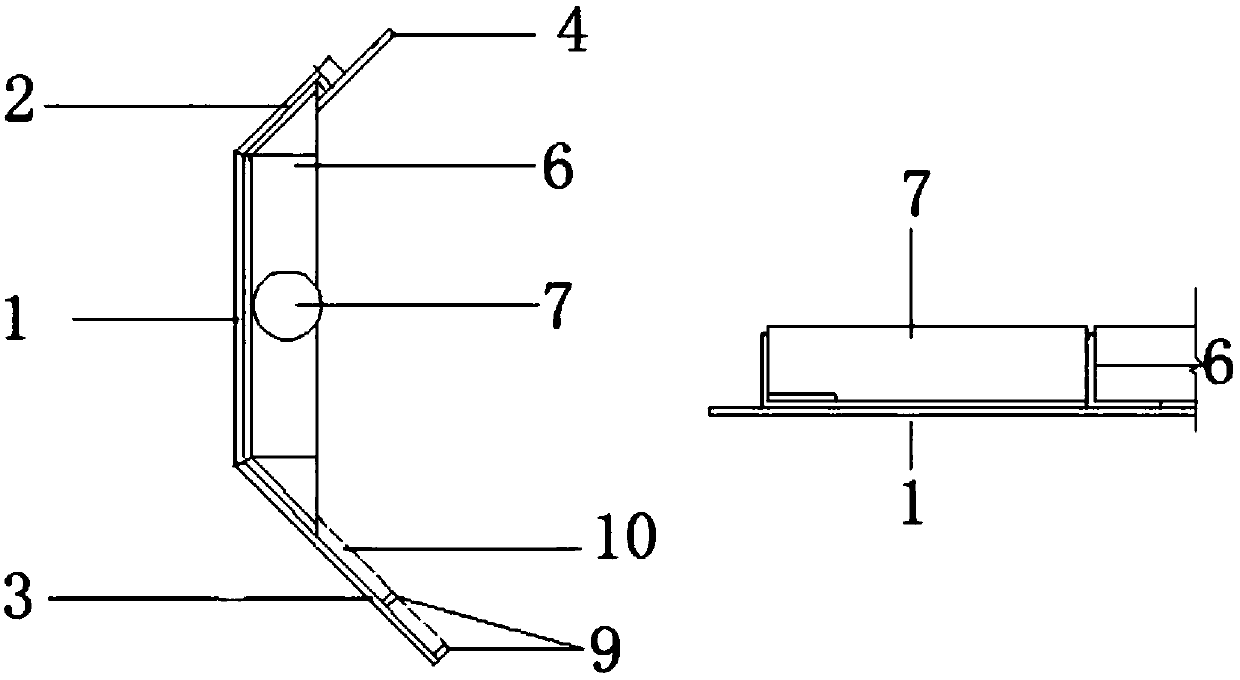

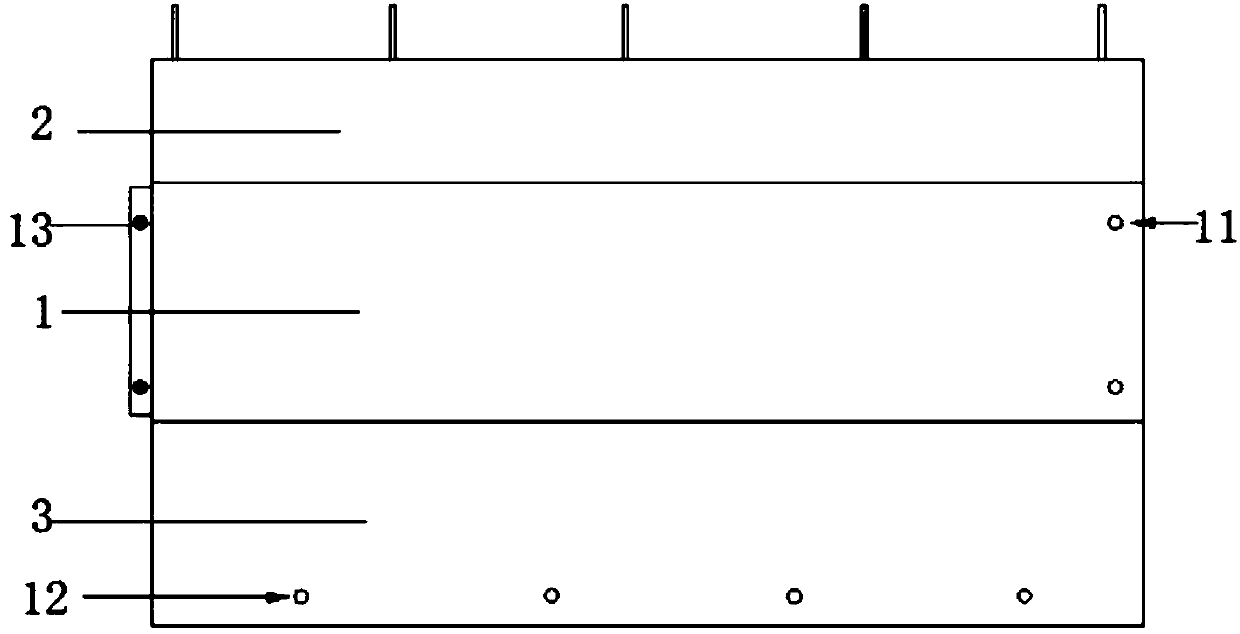

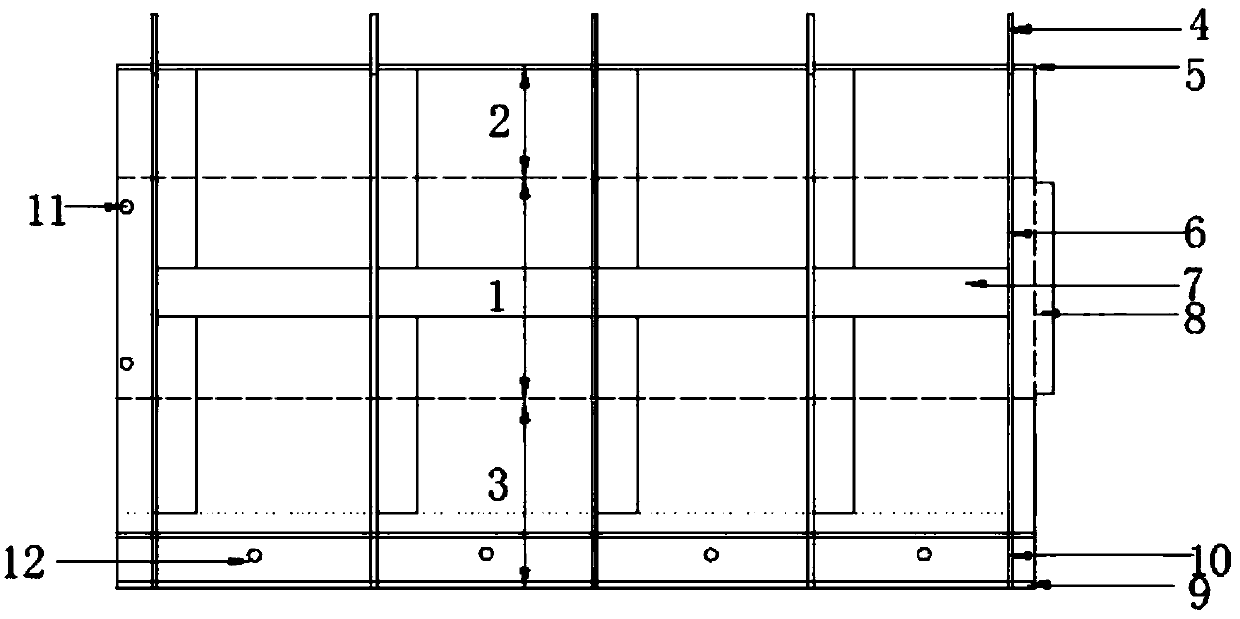

[0039] exist figure 1 Among them, a method for supporting a chamfered and shaped steel formwork in this embodiment, the chamfered and shaped steel formwork includes a web steel plate 1, an upper flange steel plate 2 and a lower flange steel plate 3, and the web steel plate 1 and the upper flange steel plate A main stiffener 5 is arranged between the flange steel plates 2; a main stiffener 5 is arranged between the web steel plate 1 and the lower flange steel plate 3; 50 steel pipes 7 are welded between the main stiffeners 5; The end of the upper flange steel plate 2 is welded with an upper flange end stand plate 6 and a drag claw 4; the lower flange steel plate 3 is welded with a longitudinal secondary stiffener 9 and a transverse secondary stiffener 10; the described One end of the lower flange steel plate 3 is provided with a plurality of bolt holes 12; one end of the web steel plate 1 is provided with a butt plate 8; the butt plate 8 is provided with a pin 13; The other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com