Metallographic corrosive agent for annealed pure titanium and titanium alloy and using method of metallographic corrosive agent

A titanium alloy and etchant technology, applied in the field of metallographic etchant preparation, can solve the problems of excessive corrosion of the sample, difficult corrosion time, corrosion damage of operators and equipment, and achieve uniform surface of the sample and clear and complete outline of grain boundaries. , The effect of convenient and quick metallographic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a metallographic etchant for annealed pure titanium TA1 and TC4 titanium alloys. The preparation and use methods are as follows:

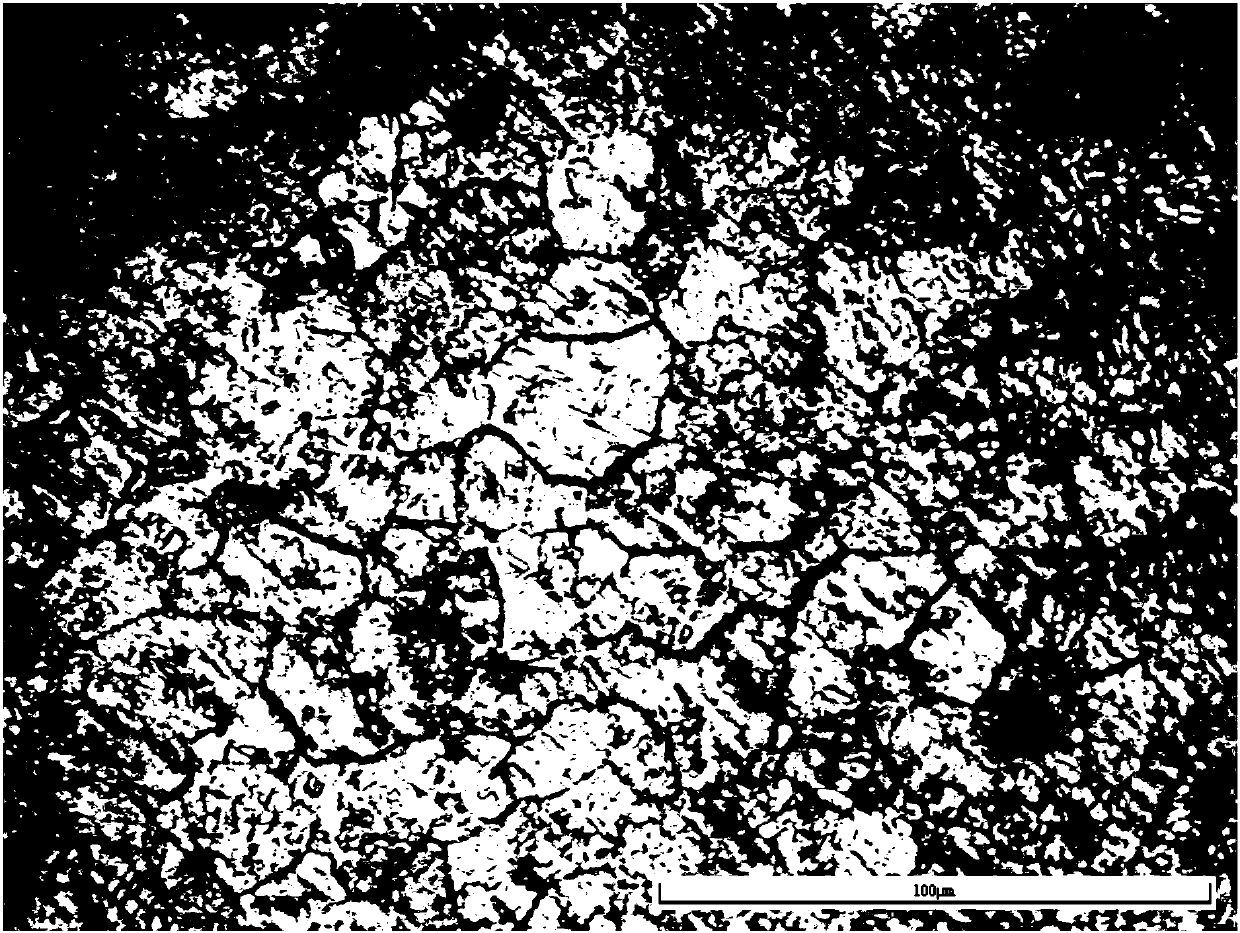

[0031] First 60ml of dehydrated alcohol (mass fraction is 98%) is joined in the plastic container, then add analysis pure acetic acid (mass fraction is 99.5%) 30ml, citric acid (mass fraction is 60%) 10ml, the solution is mixed evenly, in At room temperature, use a plastic dropper to absorb a small amount of corrosive agent, and drop it on the surface of the polished pure titanium TA1 precision forged bar metallographic sample surface and the pure titanium TA1 annealed bar sample surface, the erosion time is 15s, and then rinse the surface with clean water , and then use a cotton ball dipped in absolute ethanol to wipe the surface of the sample, and dry the surface with a hair dryer. The metallographic structure and morphology of the obtained pure titanium TA1 precision forged rod are shown in figure 1 , the metallo...

Embodiment 2

[0033] This embodiment provides a metallographic etchant for annealed pure titanium TA1 and TC4 titanium alloys. The preparation and use methods are as follows:

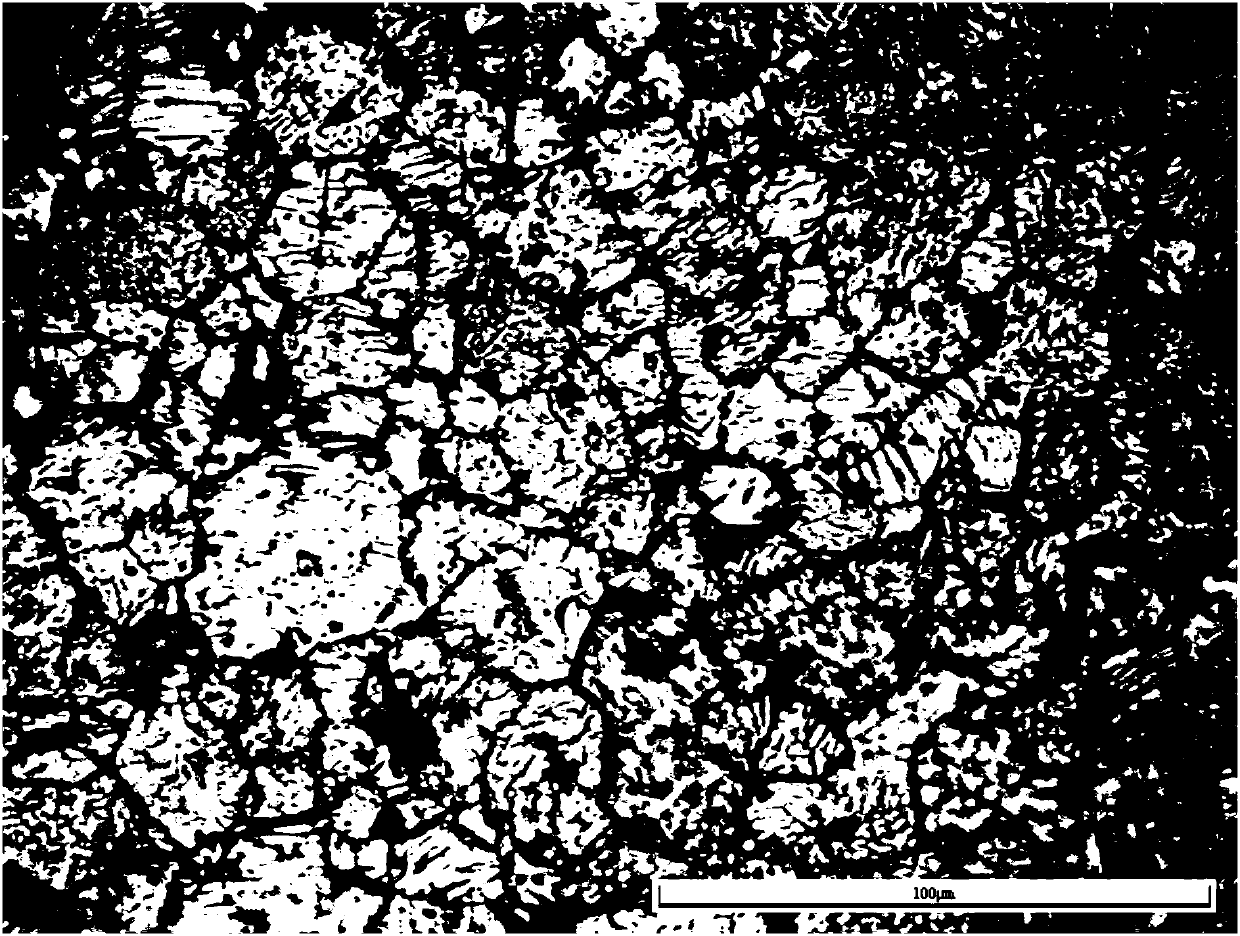

[0034] First 60ml of dehydrated alcohol (mass fraction is 98%) is joined in the plastic container, then add analysis pure acetic acid (mass fraction is 99.5%) 30ml, citric acid (mass fraction is 60%) 10ml, the solution is mixed evenly, in At room temperature, use a plastic dropper to absorb a small amount of corrosive agent, and drop it on the surface of the metallographic sample of the polished TC4 titanium alloy hot-rolled bar and the surface of the metallographic sample of the TC4 titanium alloy annealed sheet. The corrosion time is 10 seconds, and then rinse with water. Then use a cotton ball dipped in absolute ethanol to wipe the surface of the sample, and dry the surface with a hair dryer. The metallographic structure and morphology of the obtained TC4 titanium alloy hot-rolled bars are shown in image 3 , the m...

Embodiment 3

[0036] This embodiment provides a metallographic etchant for annealed pure titanium TA1 and TC4 titanium alloys. The preparation and use methods are as follows:

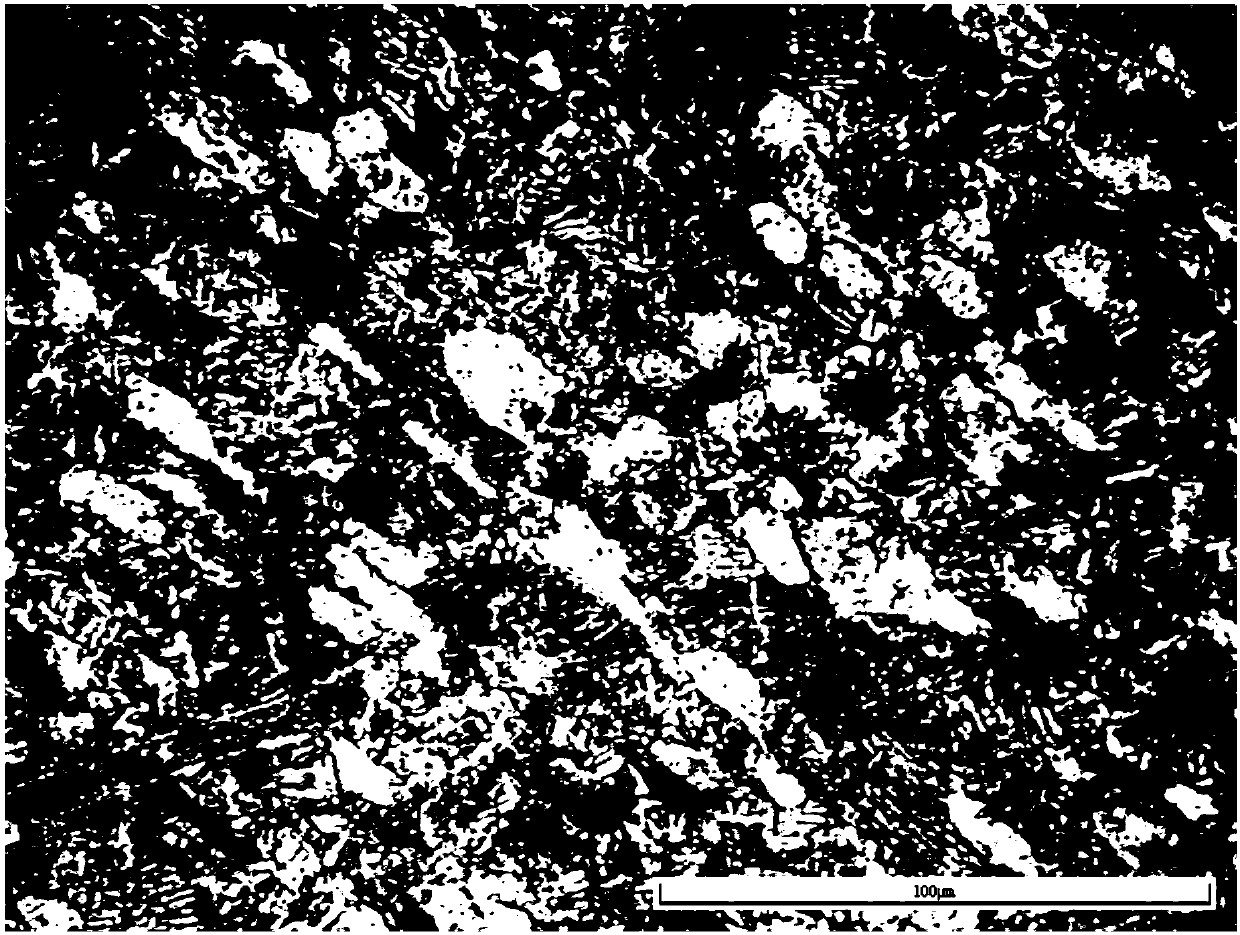

[0037] First 60ml of dehydrated alcohol (mass fraction is 98%) is joined in the plastic container, then add analysis pure acetic acid (mass fraction is 99.5%) 30ml, citric acid (mass fraction is 60%) 10ml, the solution is mixed evenly, in At room temperature, use a plastic dropper to absorb a small amount of corrosive agent, drop it on the surface of the polished TC4 titanium alloy cold-rolled plate metallographic sample, etch for 10 seconds, then rinse the surface with clean water, and then wipe it with a cotton ball dipped in absolute ethanol The surface of the sample was blown dry with a hair dryer. The metallographic structure and morphology of the obtained TC4 titanium alloy cold-rolled sheet are shown in Figure 5 ,Should Figure 5 The microstructure in is a basket structure formed by breaking the original β ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap