Pipeline well with cable locking mechanism

A locking mechanism and cable technology, applied in the field of pipeline wells, can solve the problems of easy theft of communication cables, high labor intensity, single structure, etc., and achieve the effects of improving laying efficiency, convenient and quick installation, and firm and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

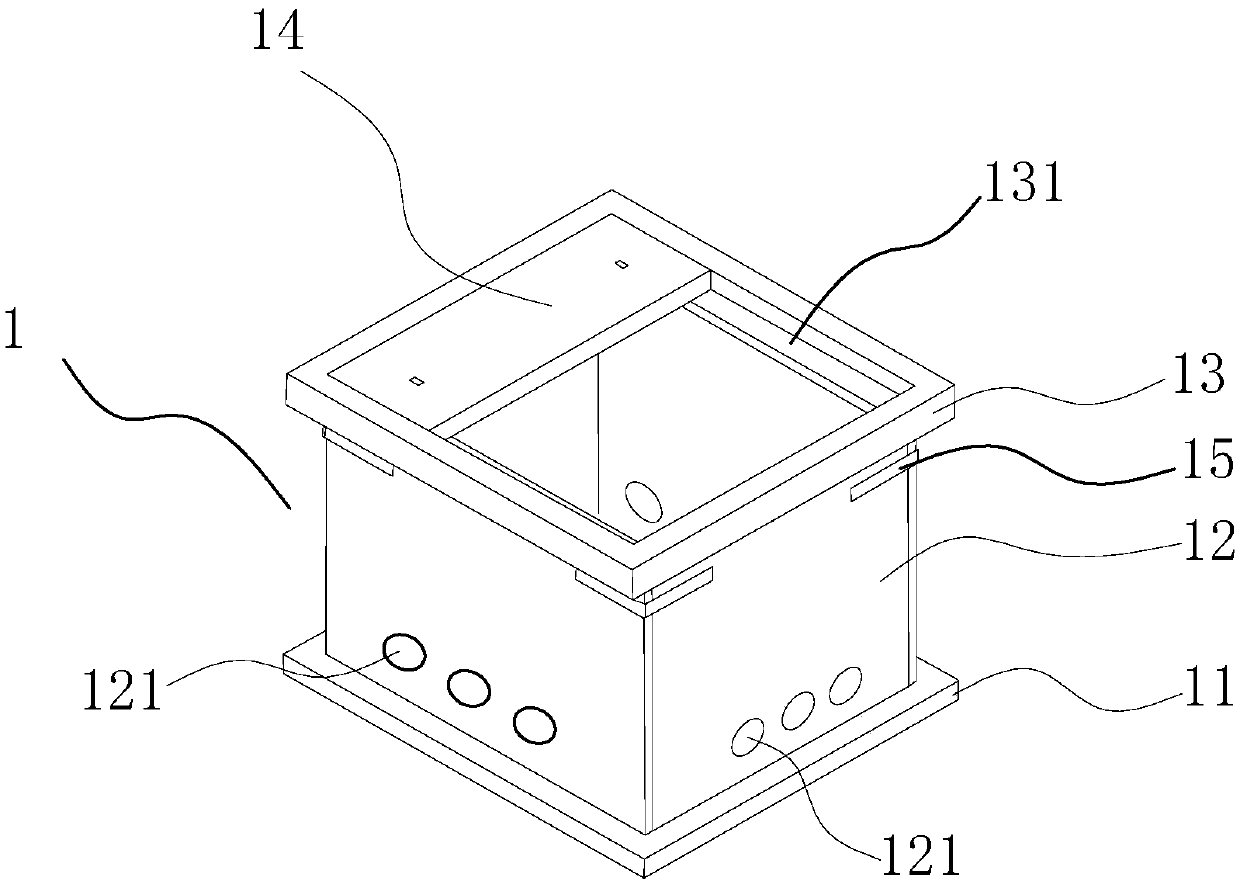

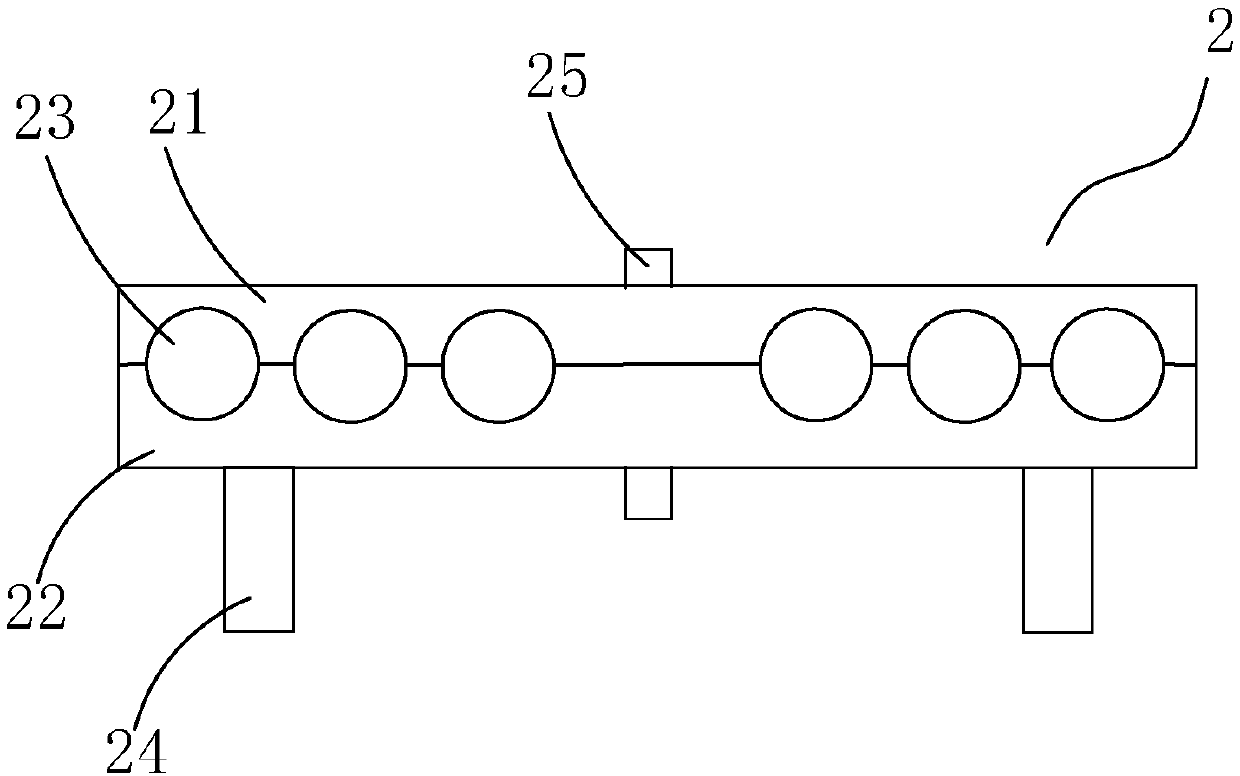

[0015] see figure 1 , a pipeline well with a cable locking mechanism provided by the present invention includes a well body 1 spliced by a prefabricated bottom plate 11 and a side plate 12, and the bottom plate 11 is provided with a slot for fixing the side plate 12 Each side plate 12 is plugged into the card slot and is fixedly connected between adjacent side plates 12 by corner fittings 15. The upper end of the side plate 12 is connected with a well base 13, and the bottom of the well base 13 is provided with a 12 matching limit grooves, the upper part of the well base 13 is provided with a concave platform 131 for assembling the cover plate 14, and at least two side plates 12 are provided with cable ports 121, and the pipeline well is composed of prefabrication and splicing. The structure is firmer and more stable, and the installation is more convenient and fast, which greatly improves the laying efficiency of communication cables, and is conducive to the later replaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com