Temperature control valve group of fan coil

A technology for fan coil units and temperature control valves, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as changing pipelines, excessive pressure in pipelines, blocked backflow, etc., and achieve fast and convenient construction and good market promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with preferred embodiments.

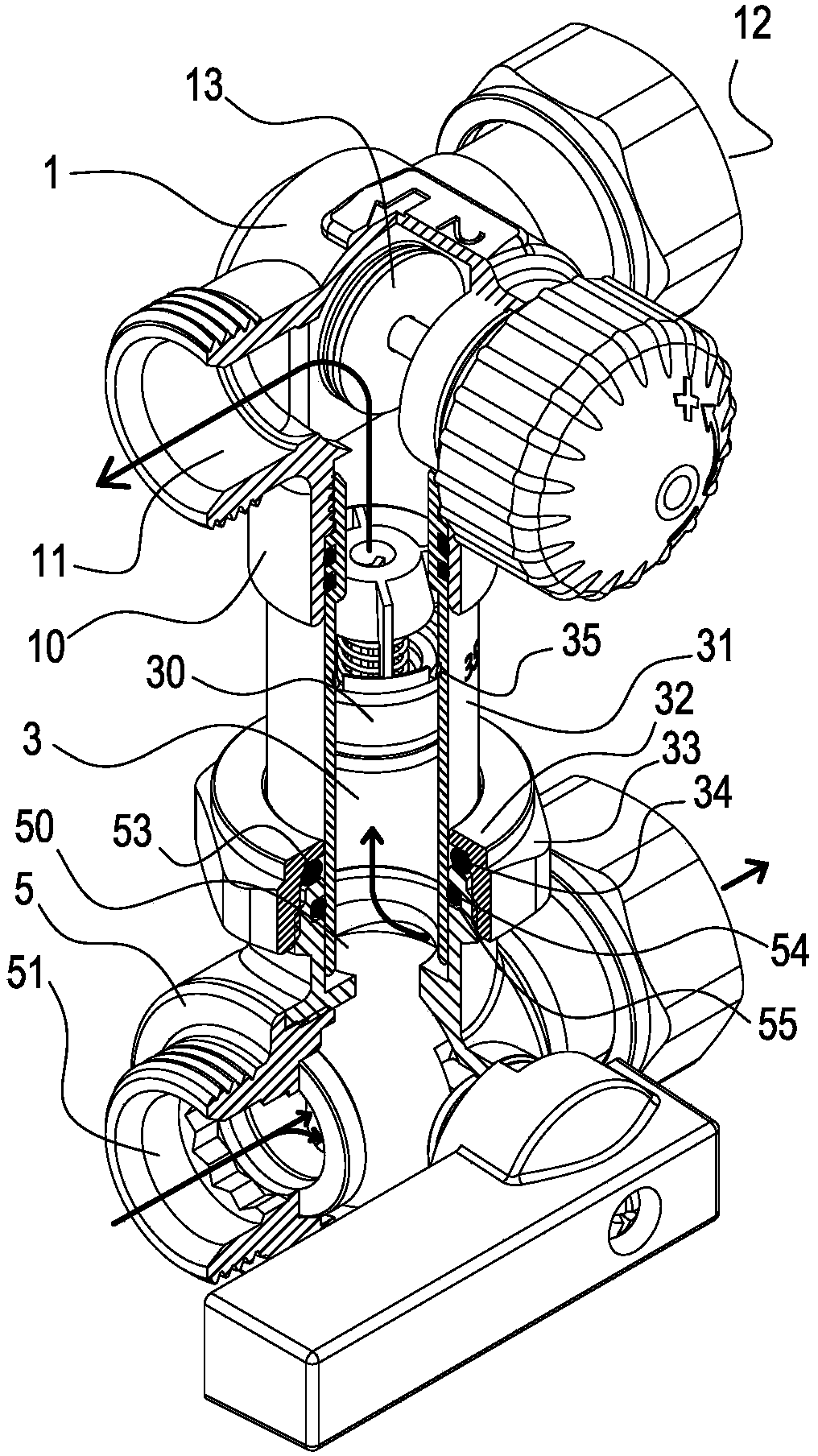

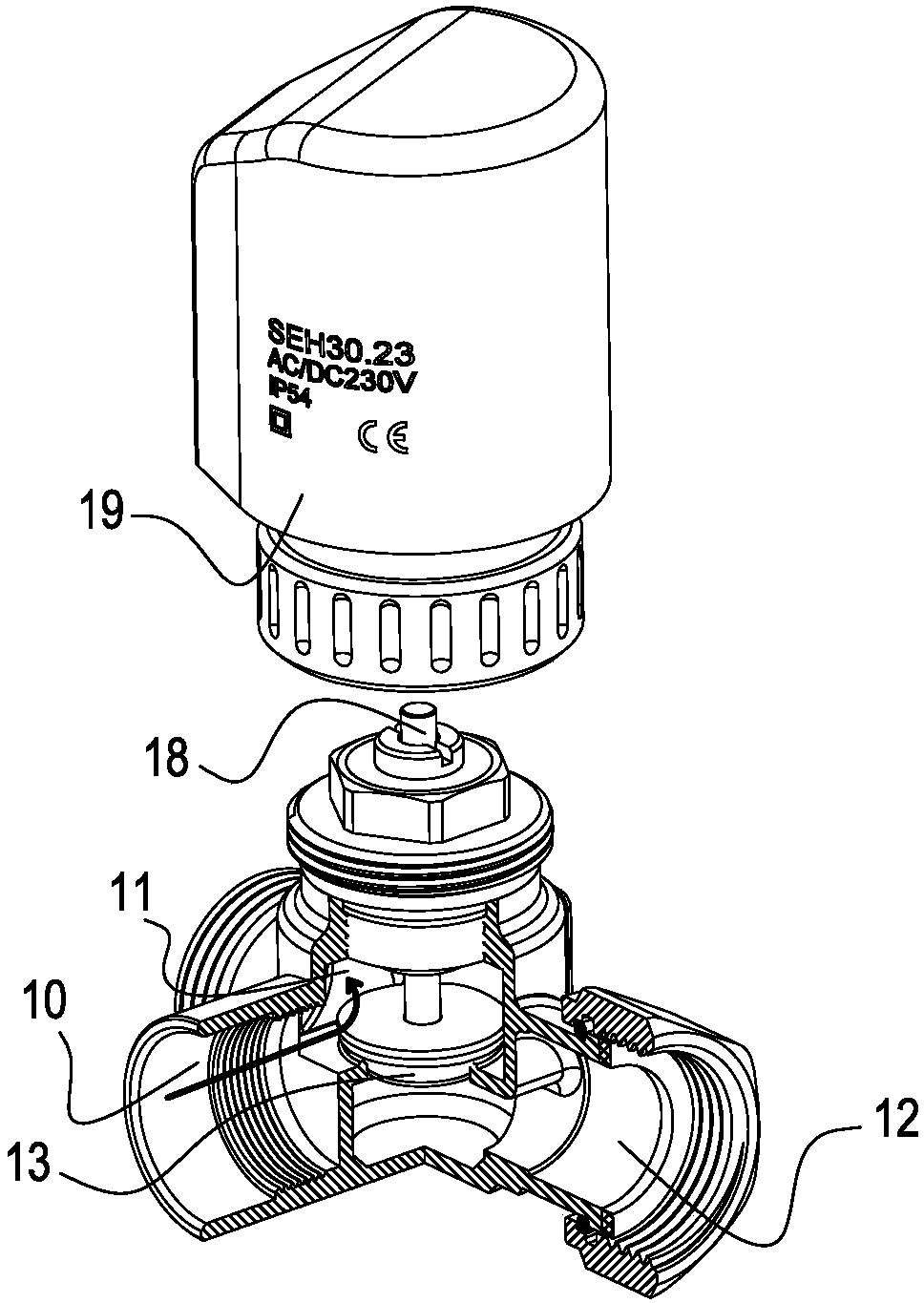

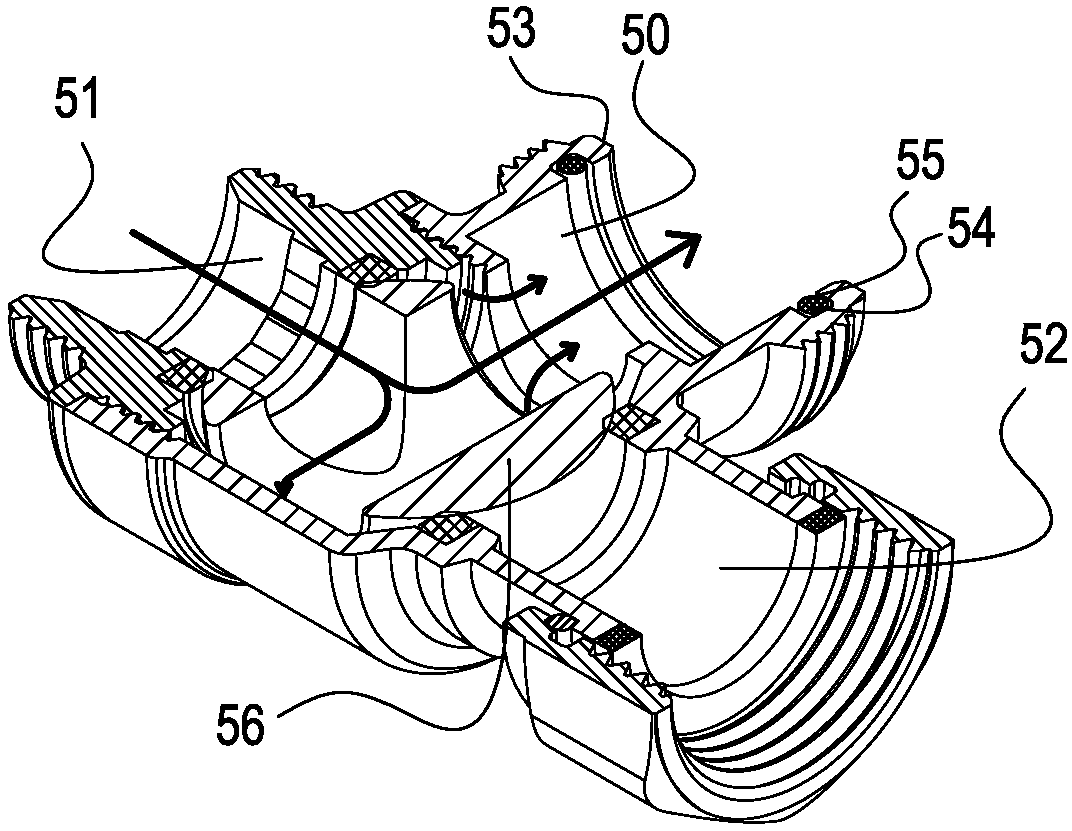

[0019] like Figure 1 to Figure 3 As shown, a fan coil temperature control valve group includes a three-way side-inlet regional valve 1, and the lower port 10 of the three-way side-inlet regional valve 1 communicates with a middle cavity 3, and the middle cavity 3 is equipped with The pressure difference spool part 30 of the top stop is connected to the upper port 50 of the three-way side goal valve 5; the lower water inlet 51 at the left end of the three-way side goal valve 5 is always connected with the middle cavity 3; the three-way The upper water outlet 11 at the left end of the side entry area valve 1 is always in communication with the middle cavity 3, and is opened and closed through the area valve core 13 and the upper water inlet 12; the outer wall of the middle cavity 3 is an extension pipe part 31, the extension pipe The part 31 is separated from the ball valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com