Prefabricated communication cable wiring groove

A technology for communication cables and wiring troughs, applied in the field of wiring troughs, can solve problems such as unfavorable cable replacement, maintenance and overhaul, easy damage to the surface of cables, and unguaranteed safety, so as to improve laying efficiency , Easy and fast installation, time-saving and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

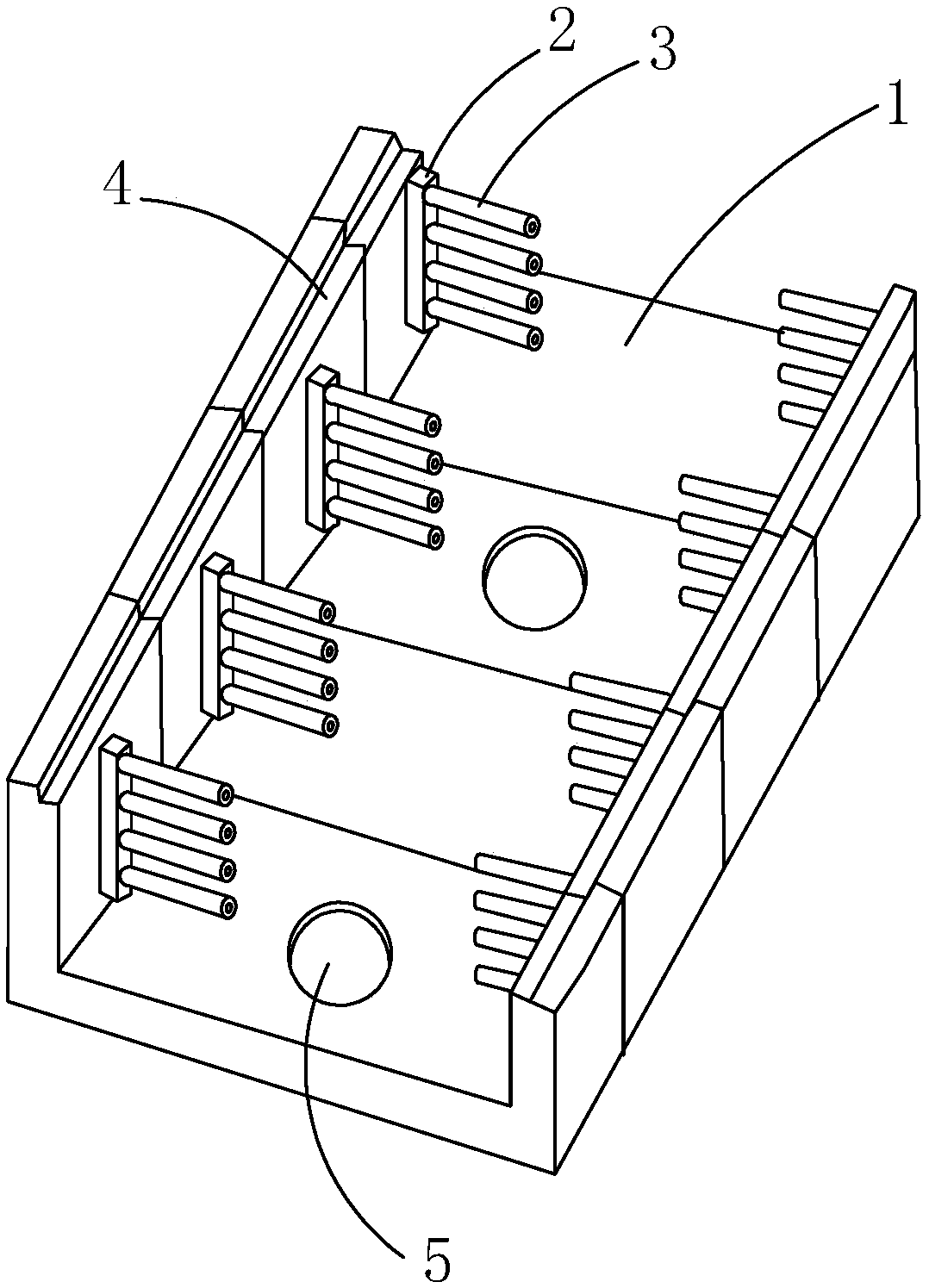

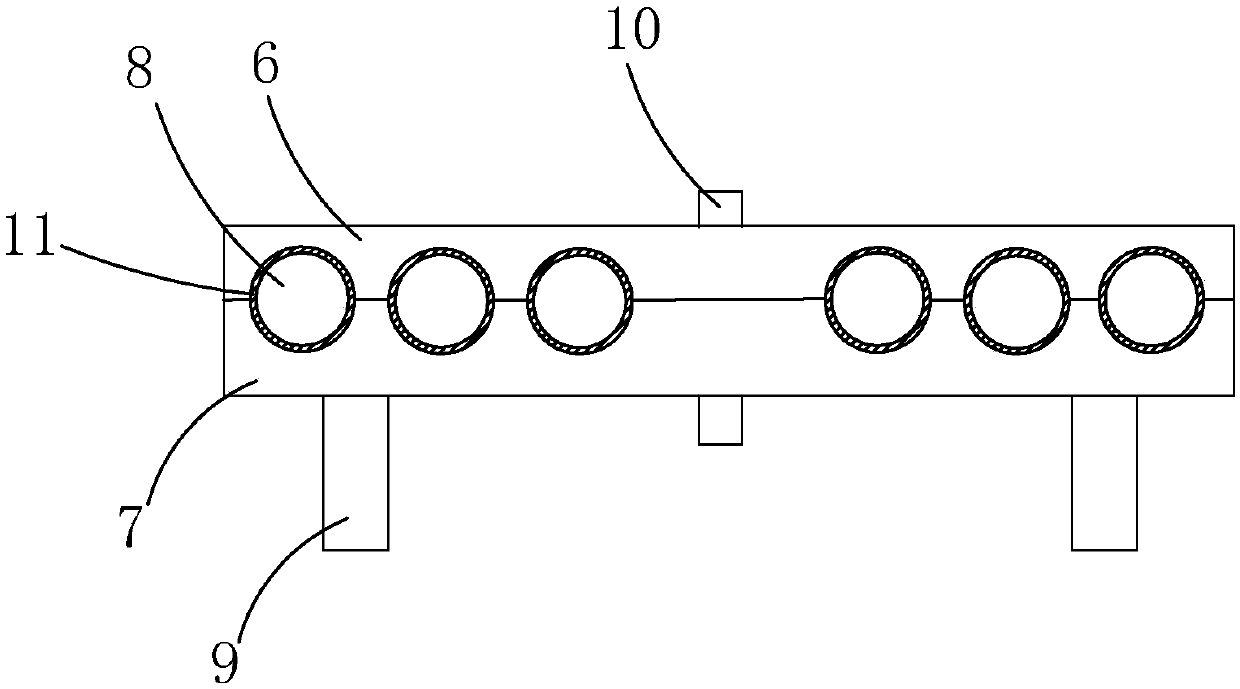

[0016] see figure 1 , a prefabricated communication cable routing trough provided by the present invention, including a trench formed by splicing a plurality of U-shaped prefabricated parts 1, adjacent prefabricated parts 1 are fixedly connected by fasteners, and each prefabricated part 1 Bosses are provided on the tops of both sides, and slots 4 for installing cover plates are provided on the bosses. Composed of prefabrication and splicing, the structure is firm and stable, and the installation is more convenient and quick, which greatly improves the laying efficiency of communication cables, and is conducive to the later replacement, maintenance and repair of cables. At the same time, a bracket 2 for supporting communication cables is provided on the inner wall of each prefabricated part 1, and a roller 3 perpendicular to the laying direction of the communication cable is arranged on the bracket 2, and the roller 3 on the bracket 2 can assist in laying wires. It can greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com