An ellipsoid helical surface profiling mechanism and its control method

A technology of spiral surface and profiling mechanism, applied in the direction of copying process control system, manufacturing tools, metal processing equipment, etc., can solve the problems of geometric shape influence, limit the fineness of profiling and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

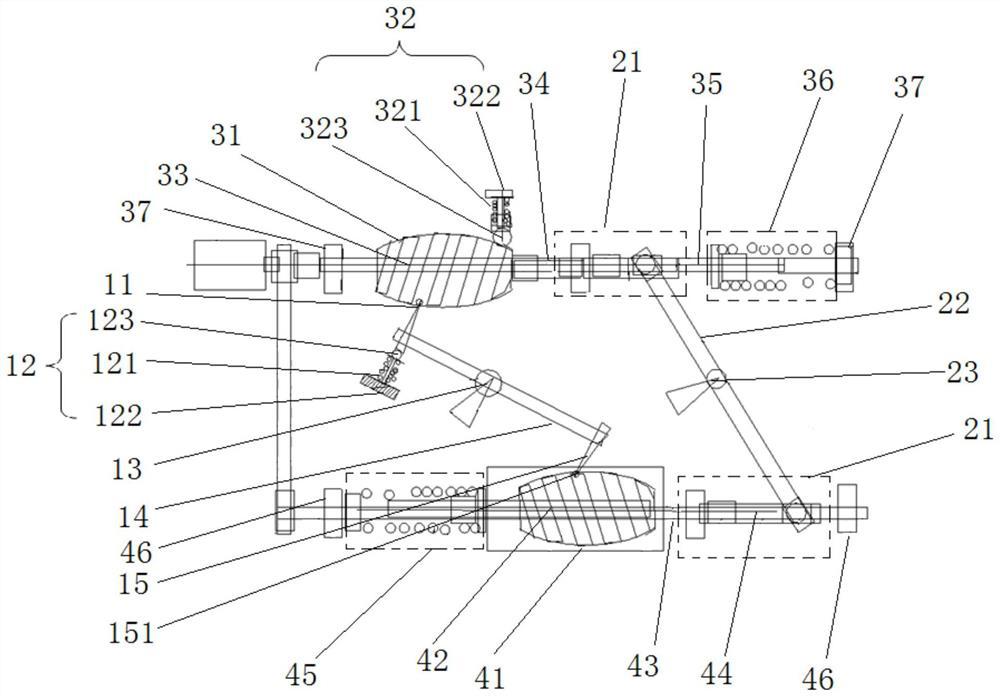

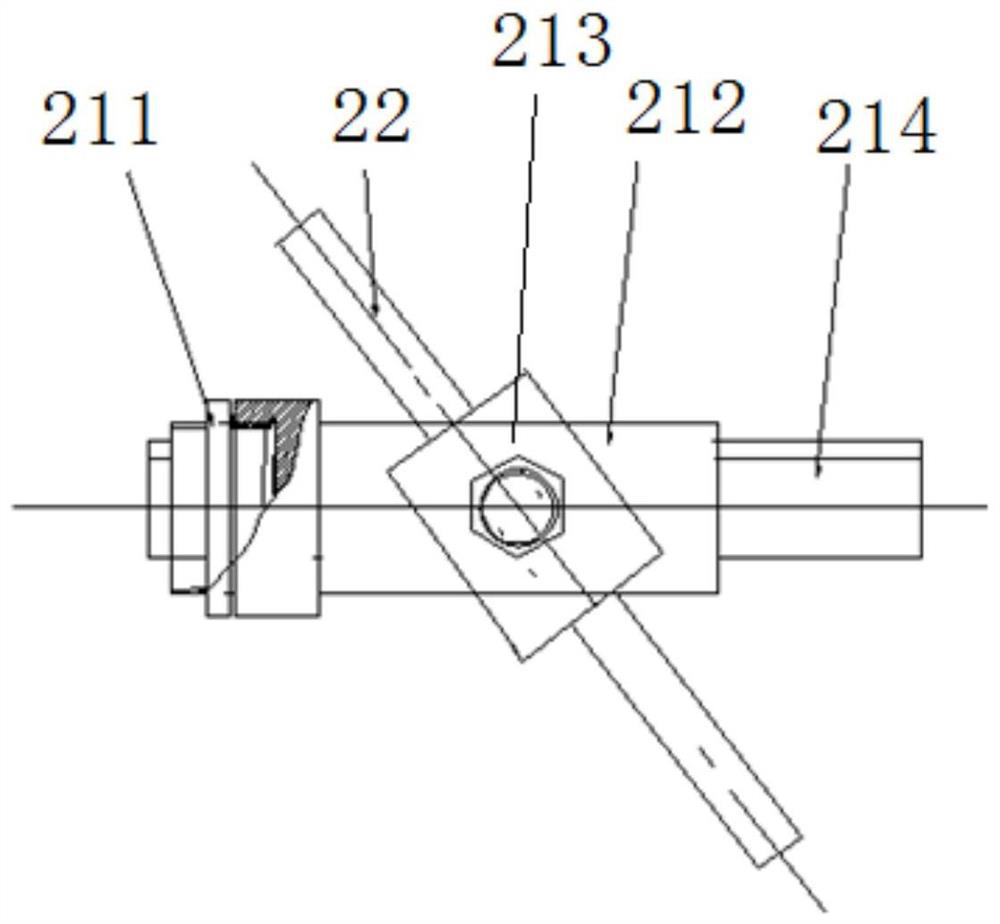

[0081] Specific implementation mode one, please refer to Figure 1-5 , an ellipsoidal spiral curved surface profiling mechanism, comprising a lever scaling unit 1, a lever reverse dialing unit 2, a template ellipsoidal movement unit 3 and a workpiece body movement unit 4;

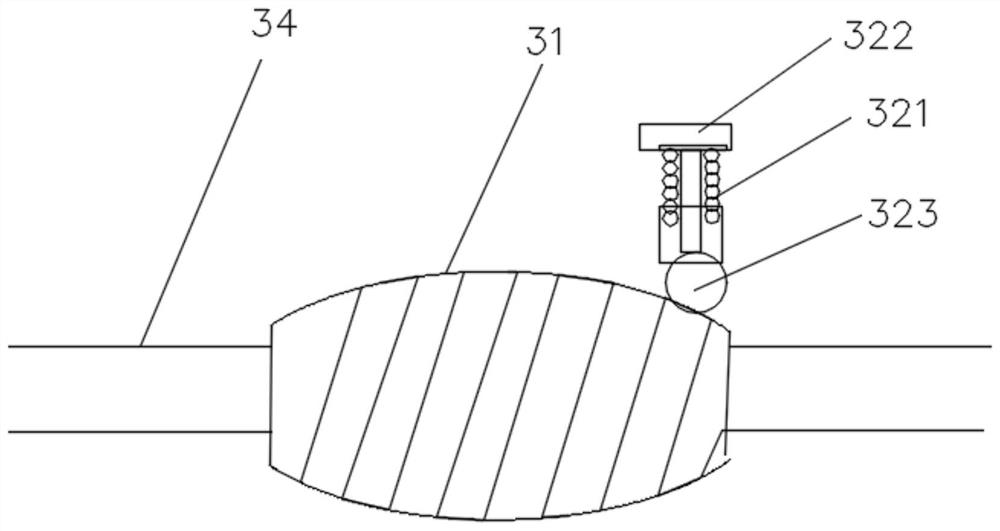

[0082] The template ellipsoid motion unit 3 includes a template ellipsoid 31 and an axial limit rolling element assembly 32, and the axial limit rolling element assembly 32 abuts against the template ellipsoid 31; the template ellipsoid 31 has The first axis 33, the stencil ellipsoid 31 can rotate around the first axis 33 and at the same time move linearly along the first axis 33 under the action of the axial limiting rolling element 32 assembly;

[0083] The workpiece blank moving unit 4 includes a workpiece blank 41, the workpiece blank 41 has a second axis 42 parallel to the first axis 33, and the workpiece blank 41 can Rotating around the second axis 42 while moving linearly along the second axis 42, t...

specific Embodiment approach 2

[0093] Specific implementation mode two, please refer to image 3 , this embodiment is basically the same as Embodiment 1, the difference is that the manufacturing part of the scaling mechanism includes a 3D printing head 152 and a printer assembly 153, and the 3D printing head 152 is arranged on the manufacturing part 15 of the scaling mechanism At the tip part, the 3D printing head 152 is in contact with the working piece blank 41 , and is used to obtain a working piece blank with a convex ellipsoidal spiral surface.

specific Embodiment approach 3

[0094] Specific implementation mode three, please refer to Figure 6 , this embodiment is basically the same as Embodiment 1, the difference is that the zoom mechanism component part 15 includes a milling cutter 154 and a motor assembly 155, and the milling cutter 154 is arranged at the tip of the zoom mechanism component part 15 part, the milling cutter 154 is in contact with the workpiece blank 41 , the shape of the milling cutter 154 is spherical, and is used to process the spiral groove on the surface of the workpiece blank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com