A push-type topping machine that can collect cotton buds

A topping machine and budding technology, applied to agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of rolling, easily delaying farming time, and affecting popularization and application, so as to reduce the radius of gyration, improve adaptability, Ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

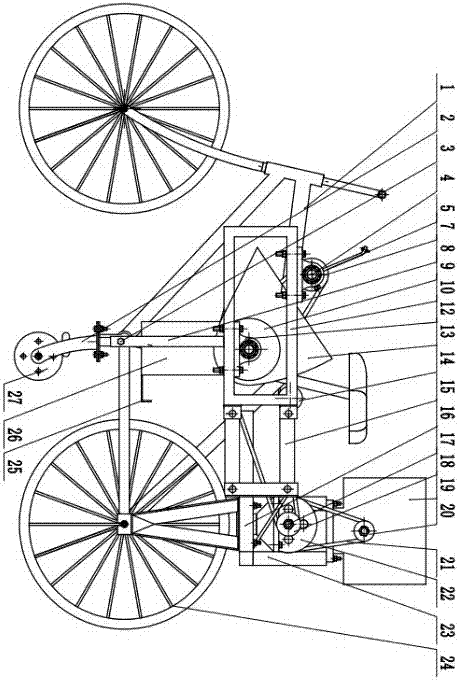

[0023] in figure 1 In this, first fix the rear frame 23 on the rear seat 16 of the bicycle 1, fix the engine 19 on the rear frame 23, and ensure that the engine 19 is located directly above the rear seat 16 of the bicycle 1, and then fix the support wheels 24 on On the long slot 6 of the rear frame 23; ensure that the rear frame 23 is in a horizontal state. The profiling wheel 27 is inserted into the front frame supporting square tube 8 through the profiling wheel column 2 and locked with a fastening screw 3; then the front frame 10 and the rear frame 23 are connected with a four-bar profiling frame 15; The auger 9 is fixed on the lower side of the rectangular front frame 10 with a bearing seat 12, and the auger bottom groove 13 is fixed on the front frame 10; the cutter shaft 4 is fixed on the upper side of the front frame 10 with a bearing seat 12.

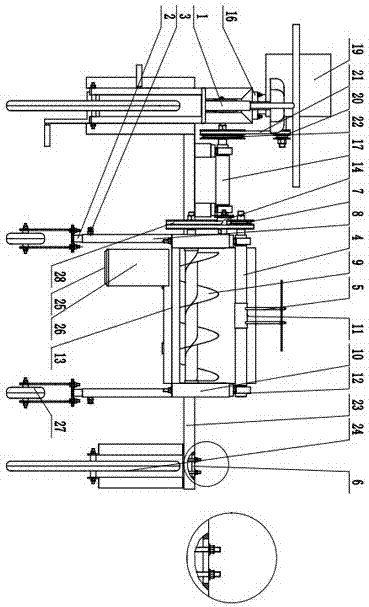

[0024] in figure 2 In the middle, the top cutter assembly 5 is threaded on the cutter shaft 4 and locked with the positioning sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com