Adjustment Structure of Spherical Forming Die for Spoke Cap

A technology for forming molds and caps, which is applied to the adjustment structure field of spherical surface forming molds for spoke machines, can solve the problems of complicated disassembly and assembly process, affecting production, long adjustment time, etc., and achieves simple adjustment, reasonable structure, and guaranteed quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

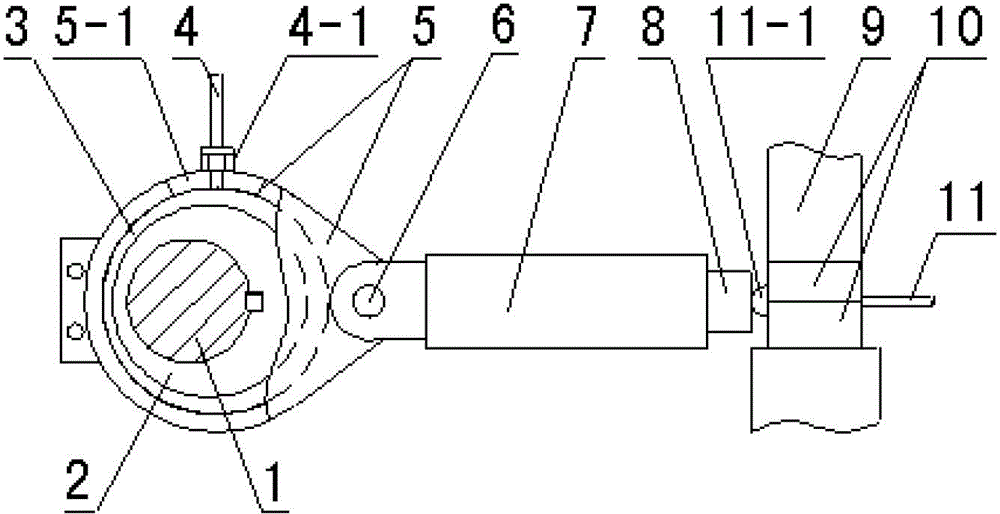

[0010] In the embodiment shown in the figure, the eccentric wheel 2 is fixed on the power output main shaft 1 of the spoke machine through a connection key, and the outer edge of the eccentric wheel 2 is fitted with an eccentric adjustment ring 3, that is, the inner surface of the eccentric adjustment ring 3 is in sliding fit with the eccentric wheel.

[0011] The eccentric wheel 2 and the eccentric adjustment ring 3 are provided with a splint type cam disc 5, and the eccentric adjustment ring 3 is in sliding fit with the inner circle of the splint type cam disc 5. The splint type cam disc 5 transverse flange is connected with the pier cap punch rod 7 by the shaft 6, and the other side corresponding to the splint type cam disc 5 and the transverse flange is connected and fixed by bolts.

[0012] The outer circle of the eccentric adjustment ring 3 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com