A die-cutting mold for automotive interior parts

A technology for automotive interior parts and forming molds, which is applied to household appliances, household components, and other household appliances. It can solve the problems of slow production speed, high labor cost, and long production cycle, so as to improve work efficiency and achieve good molding effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

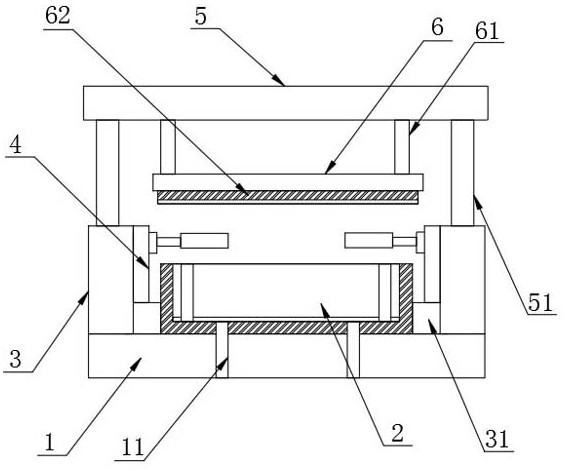

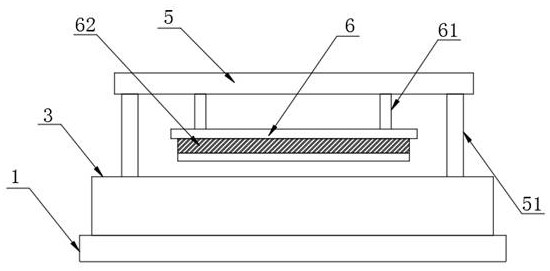

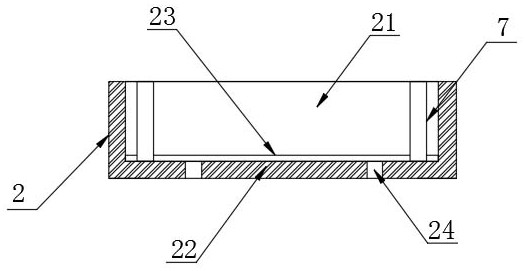

[0022] The present invention provides such Figure 1-5 A punching and forming die for automotive interior parts shown includes a base 1, a mold base 2 is provided on the top of the base 1, a mold cavity 21 is provided inside the mold base 2, and a mold cavity 21 is arranged around the outside of the mold base 1. There is a heating chamber 22, support blocks 3 are provided on both sides of the mold base 2, a punching device 4 is provided on the inner side of the support block 3, a top plate 5 is provided on the top of the mold base 2, and a top plate 5 is provided on the bottom of the top plate 5. Lifting plate 6, a fixed rod 61 is evenly arranged between the lifting plate 6 and the top plate 5, and a heating plate 62 is arranged at the bottom of the fixing rod 61, and the inside of the heating chamber 22 and the heating plate 62 are filled with heating coils.

[0023] Beneficial effects of this embodiment:

[0024] The hot-melted molding raw material is extruded into the mold...

Embodiment 2

[0026] A cavity bottom plate 23 is provided at the bottom of the inner wall of the cavity 21 , and a communication hole 24 is formed inside the heating cavity 22 , and the communication hole 24 communicates with the cavity bottom plate 23 .

[0027] The base 1 is provided with a first electric push rod 11 inside, and the first electric push rod 11 penetrates through the heating chamber 22 and is fixedly connected with the mold cavity bottom plate 23 through a communication hole 24 .

[0028] Beneficial effects of this embodiment: After the decorative parts in the mold 21 are formed, the first electric push rod 11 can work to support the bottom plate 23 of the mold cavity, thereby ejecting the decorative parts on the top of the bottom plate 23 of the mold cavity, which is convenient for the decorative parts For processing and removal, improve work efficiency.

Embodiment 3

[0030] A limit block 31 is provided between the support block 3 and the mold base 2 , and a hydraulic lifting rod 51 is evenly provided between the top plate 5 and the support block 3 .

[0031] The punching device 4 includes a slide plate 41, a side plate 42, a slide block 43, a second electric push rod 44, a moving plate 45, a third electric push rod 46 and a cutting tool 47, and the slide plate 41 is arranged on the mold base 2 and Between the support blocks 3, the front side and the rear side of the slide plate 41 are provided with side plates 42, the surface of the side plate 42 is provided with a slider 43, and the slide block 43 is slidably connected with the slide plate 41, and the slide block 43 A second electric push rod 44 is arranged between the side plate 42, a moving plate 45 is arranged on the outside of the slider 43, a third electric push rod 46 is arranged between the moving plate 45 and the slider 43, and the moving A cutting tool 47 is attached to the outsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com