Structure improvement of wheel

A wheel and rim technology, which is applied in tire measurement, vehicle parts, tire parts, etc., can solve the problems of vehicle vibration, vehicle stability decline, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to achieve the above-mentioned purpose and effect, the technical means and the structure adopted by the present invention are hereby described in detail with respect to the preferred embodiments of the present invention.

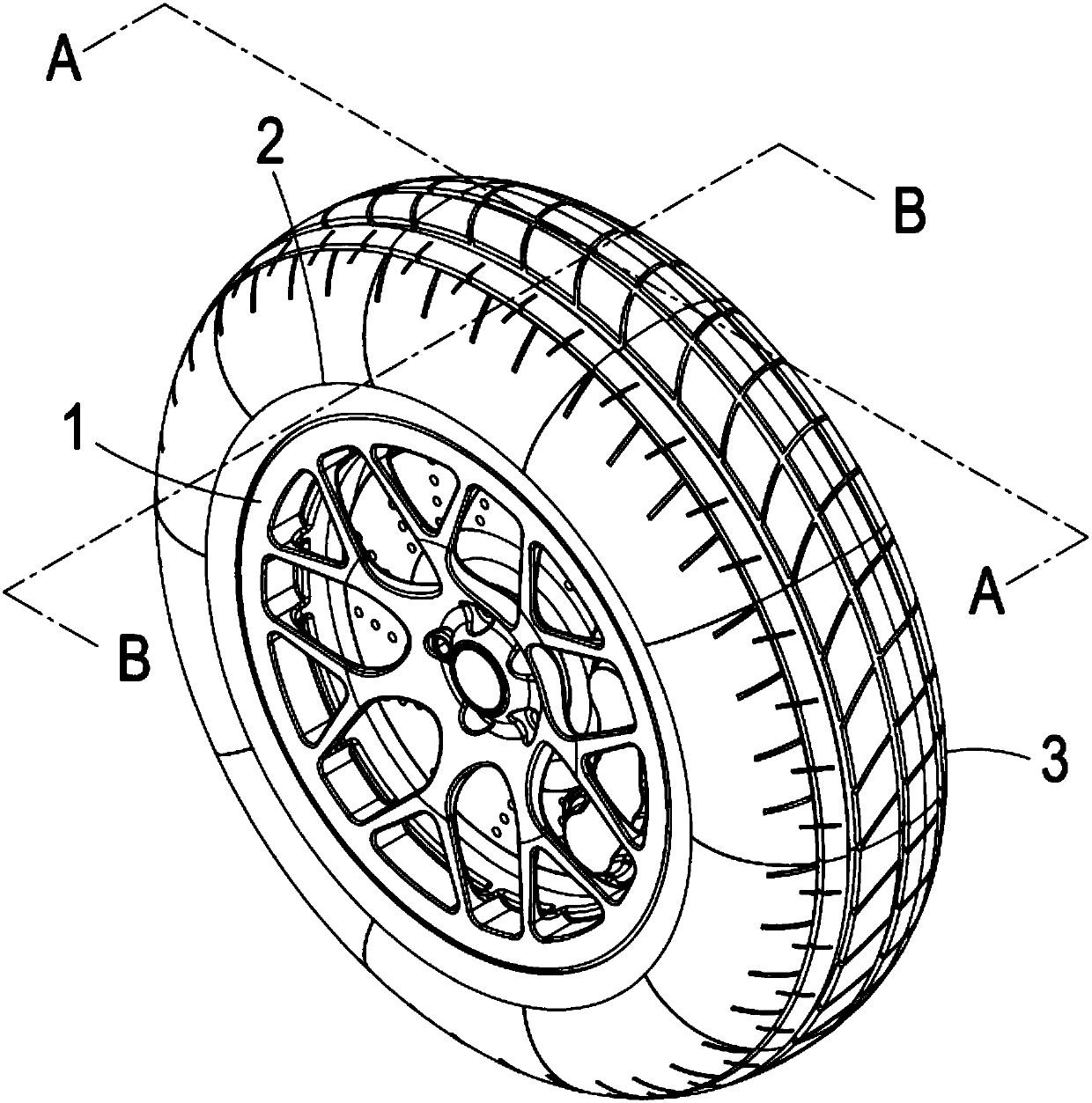

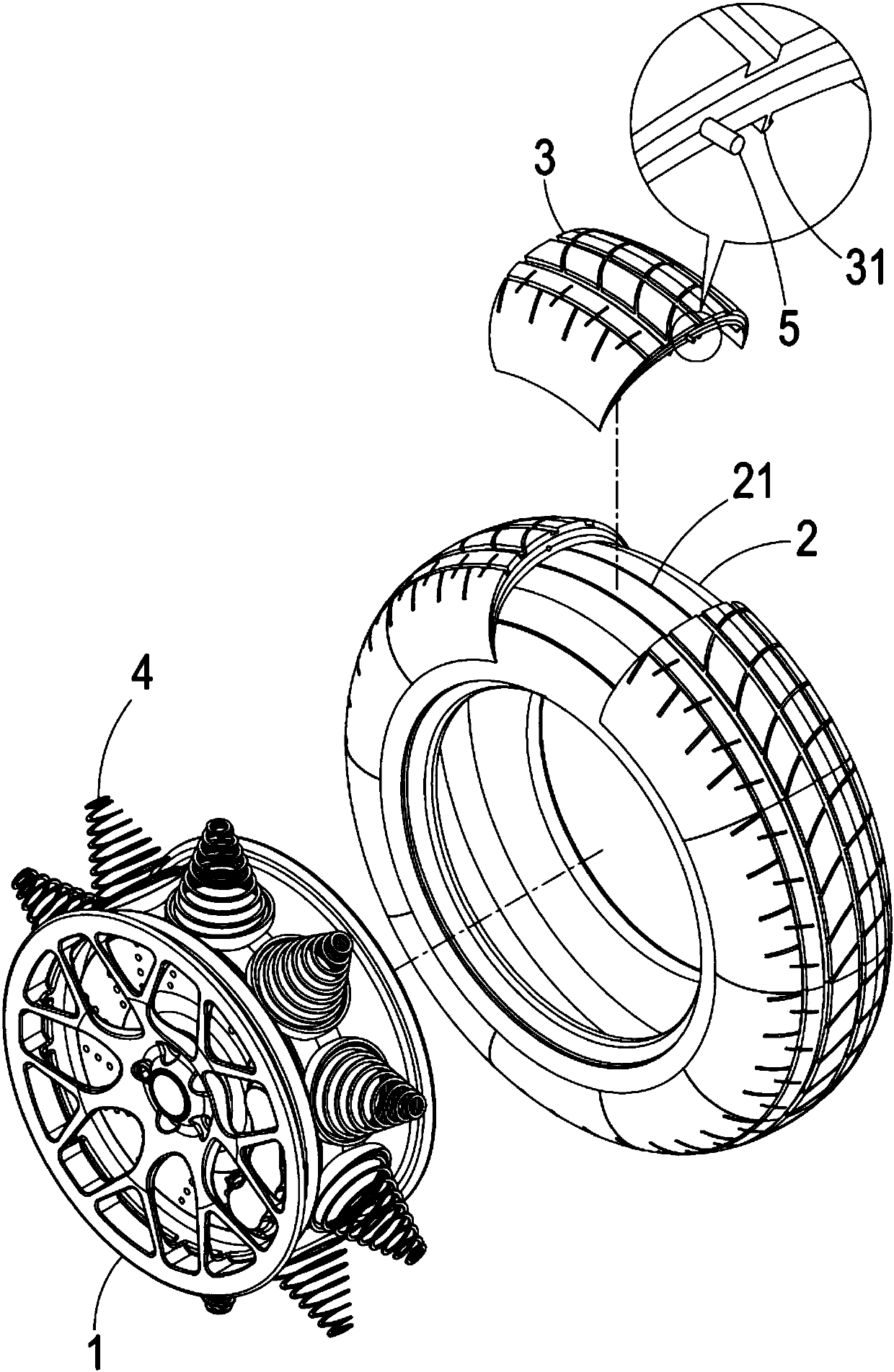

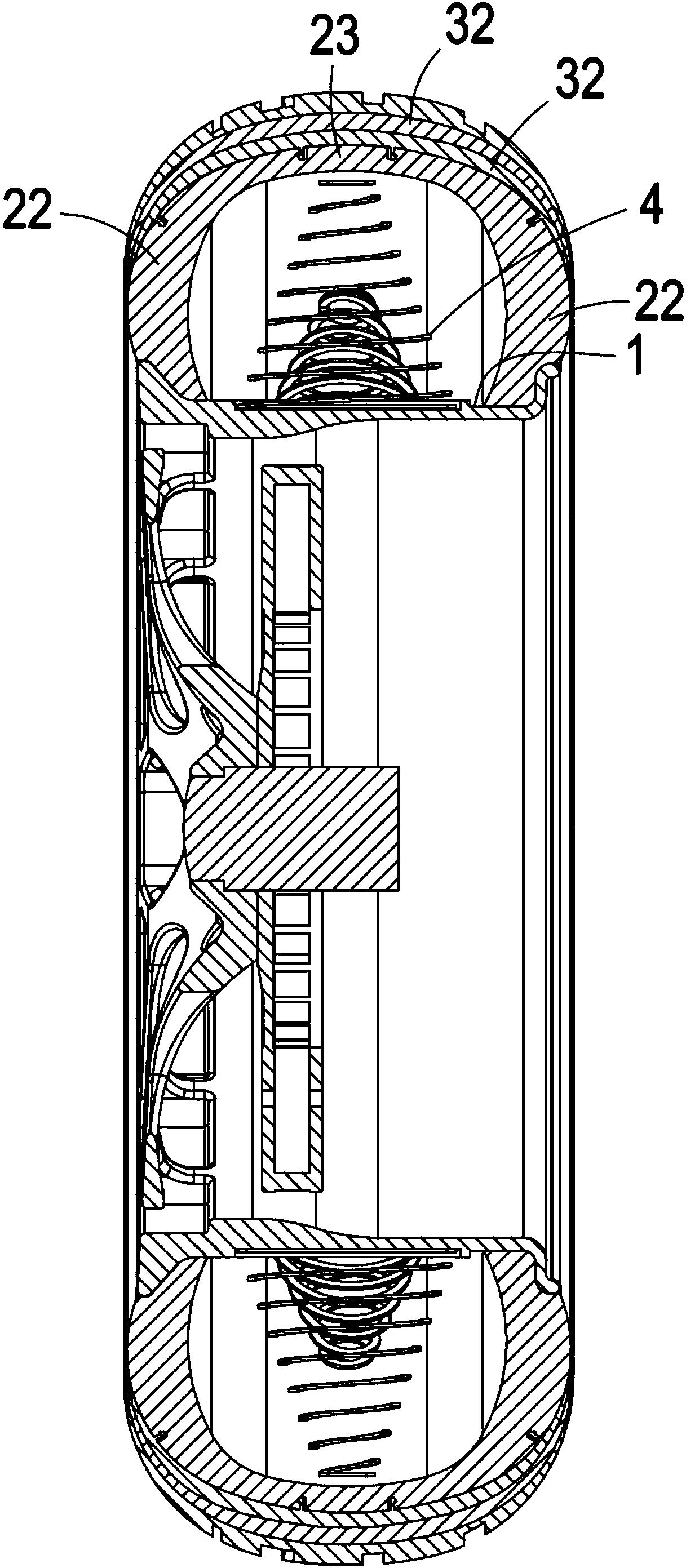

[0019] see Figure 1 to Figure 4 As shown, it is a perspective view of a preferred embodiment of the present invention to figure 1 The sectional view of BB line segment, can clearly find out that the present invention comprises from the figure:

[0020] The rim body 1;

[0021] At least one elastic part 2 with several fixing parts 21, the two sides of the elastic part 2 are connected with the side edge of the rim body 1, and the thickness of the two side walls 22 of the elastic part 2 is greater than that of the two side walls of the elastic part 2 The thickness of the top wall 23 between 22;

[0022] Several pads 3 that are detachably arranged on the elastic part 2 and have several docking parts 31 to be fixed with the fixed part, each of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com