Stacking type gray fabric circulation tray

A stacking and gray cloth technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of large storage space, high cost, and high transportation cost, and achieve the effects of reducing transportation costs, convenient transportation, and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

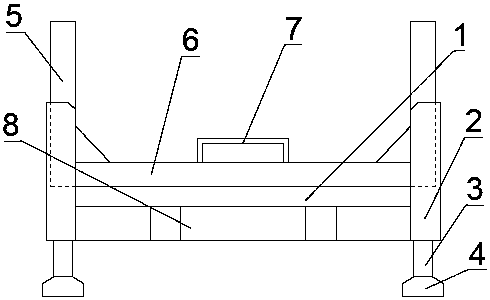

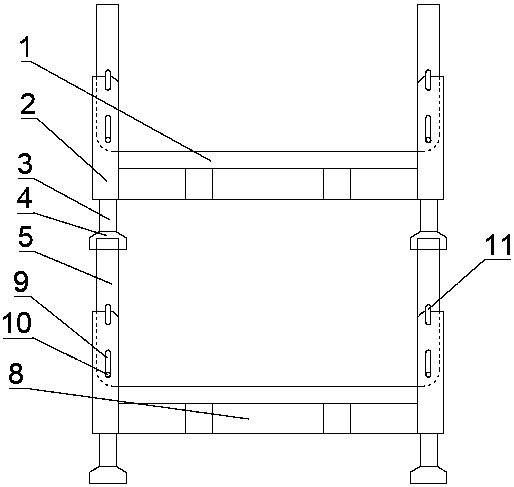

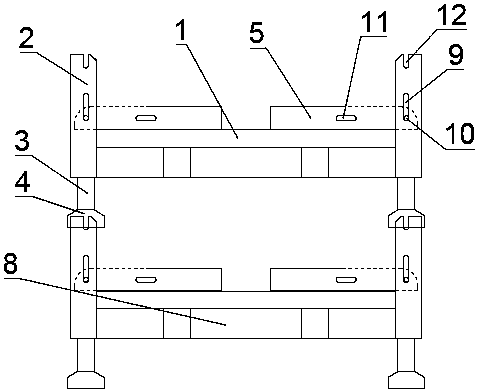

[0015] like figure 1 , figure 2 , image 3 As shown, a stacked gray cloth turnover pallet described in this embodiment includes a chassis 1 and connectors 2 arranged on the four corners of the chassis 1, and a support leg 3 is provided at the lower end of the connector 2, and the support leg 3 The lower part of the bottom is provided with footing 4, is provided with a support column 5 on each connector 2, is provided with a long hole 9 vertically on the connector 2, is provided with on the support column 5 corresponding to the slot 9 A connecting pin 10, the connecting pin 10 is located in the long hole 9, the upper end of the connector 2 is provided with an open slot 12, and a positioning pin 11 is provided on the support column 5 corresponding to the open slot 12; the support column 5 is in a vertical state , when the connecting pin 10 is located at the lower end of the long hole 9, the positioning pin 11 is located in the opening groove 12, and when the connecting pin 10...

Embodiment 2

[0017] like Figure 4 As shown, a stacked gray cloth turnover pallet described in this embodiment includes a chassis 1 and connectors 2 arranged on the four corners of the chassis 1, and a support leg 3 is provided at the lower end of the connector 2, and the support leg 3 The lower part of the bottom is provided with footing 4, is provided with a support column 5 on each connector 2, is provided with a long hole 9 vertically on the connector 2, is provided with on the support column 5 corresponding to the slot 9 A connecting pin 10, the connecting pin 10 is located in the long hole 9, the upper end of the connector 2 is provided with an open slot 12, and a positioning pin 11 is provided on the support column 5 corresponding to the open slot 12; the support column 5 is in a vertical state , when the connecting pin 10 is located at the lower end of the long hole 9, the positioning pin 11 is located in the opening groove 12, and when the connecting pin 10 is located at the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com