Material loading box

A material loading and box body technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve problems such as hidden safety hazards, tiring cleaning, inconvenience, etc., to improve convenience, improve safety, and facilitate loading and unloading. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

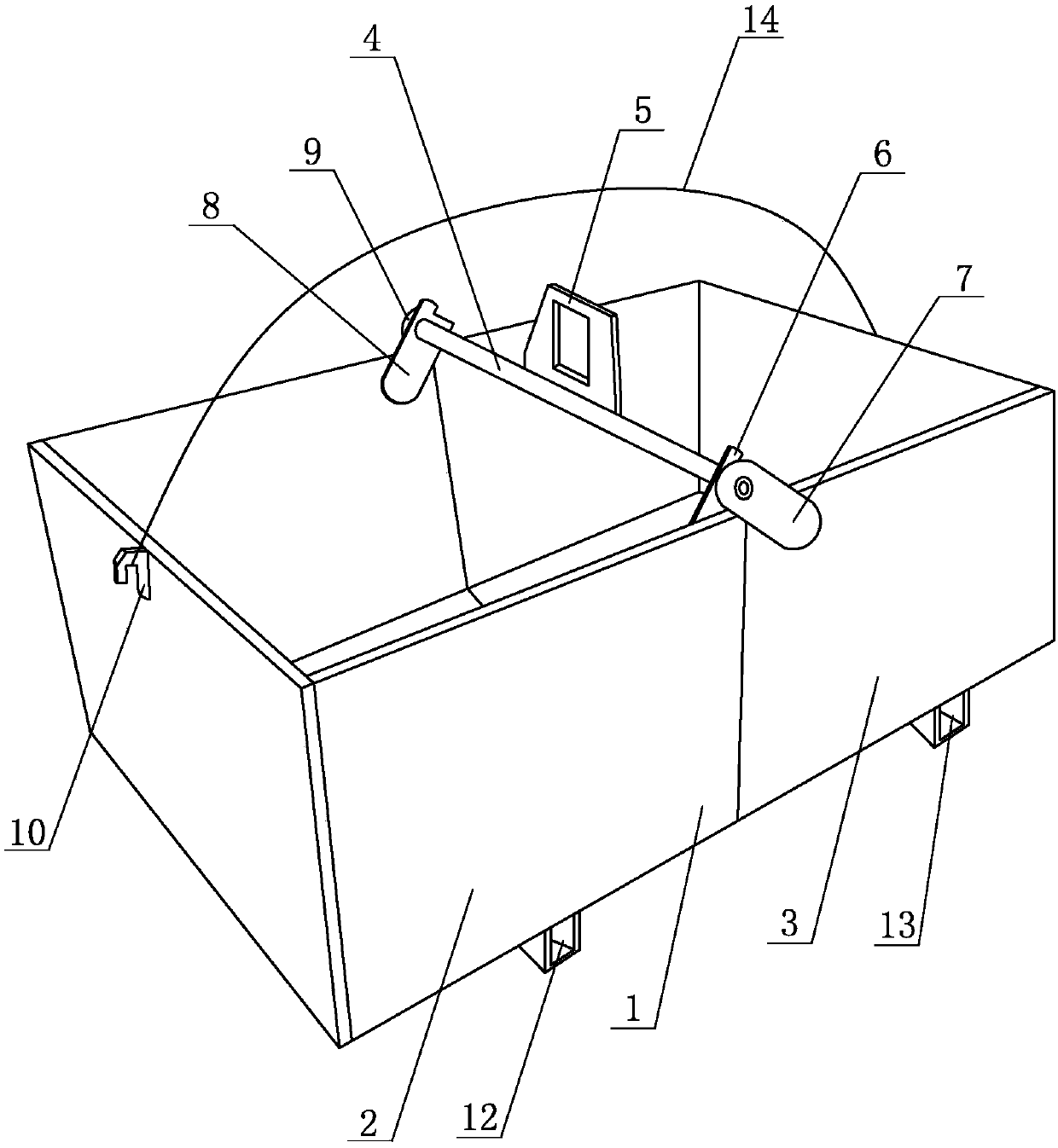

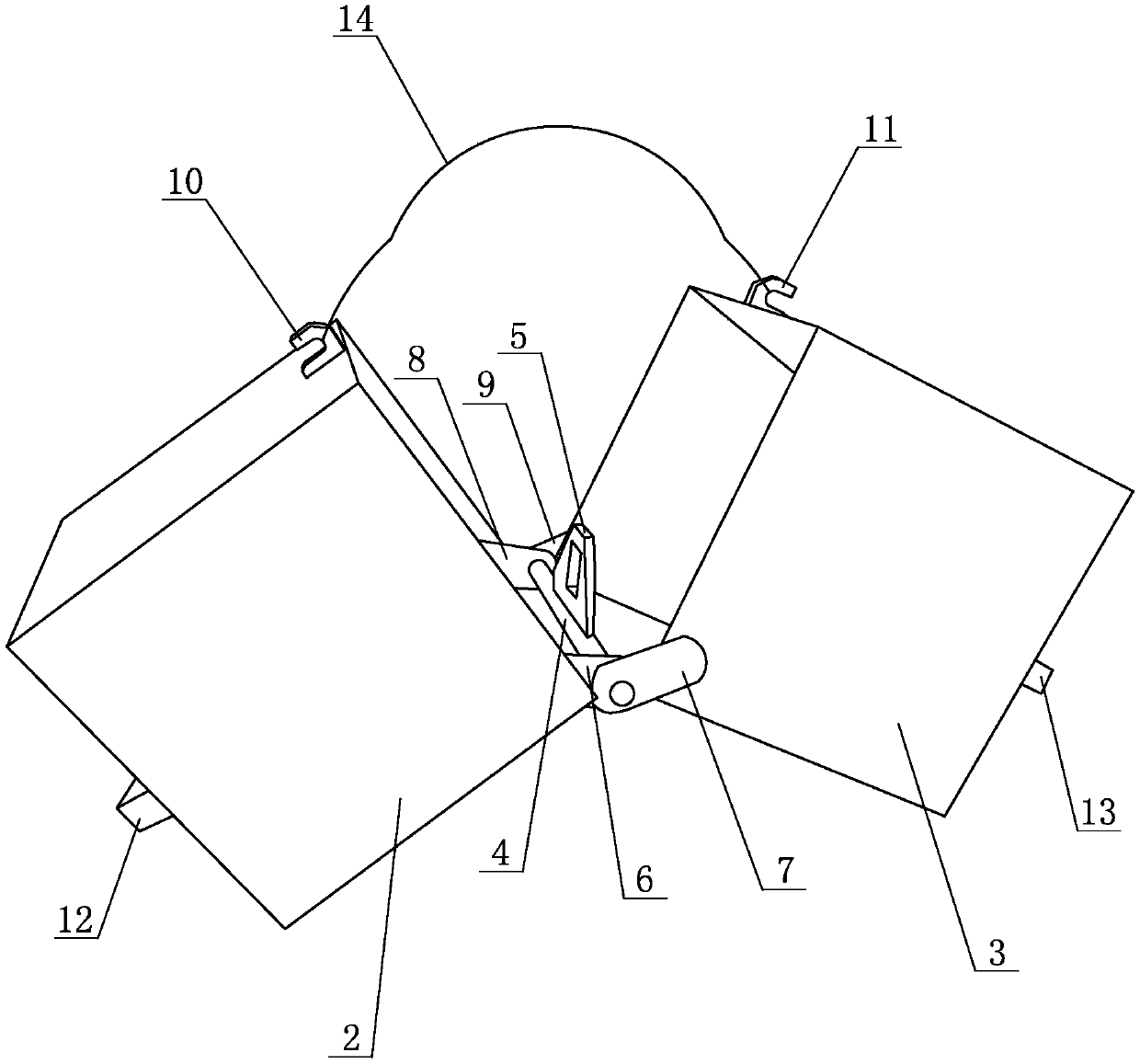

[0016] Embodiment one: see figure 1 , 2 As shown, a material loading box includes a box body 1, the box body 1 is a hollow structure with an open top, the box body 1 includes a left box body 2 and a right box body 3, and the left box body 2 is provided with Opening to the right, the right box 3 is provided with an opening to the left, the center of the box 1 is provided with a rotating shaft 4, and the front end of the rotating shaft 4 is connected to the left box 2 and the right side through the front connecting mechanism. The top front side wall of box body 3 is connected, and the rear end of described rotating shaft 4 is connected with the top rear side wall of described left box body 2 and right box body 3 through rear side connecting mechanism, and the top center of described rotating shaft 4 is also connected to each other. A pull ring 5 is provided.

[0017] see figure 1 , 2 As shown, the front connecting mechanism includes a first connecting plate 6 and a first ada...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap