Resin tank fixing structure

A technology of fixed structure and resin tank, applied in the direction of ion exchange water/sewage treatment, etc., can solve the problem of easy shaking and slipping of the resin tank, and achieve the effect of small occupied space, avoiding tilting and shaking, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the drawings.

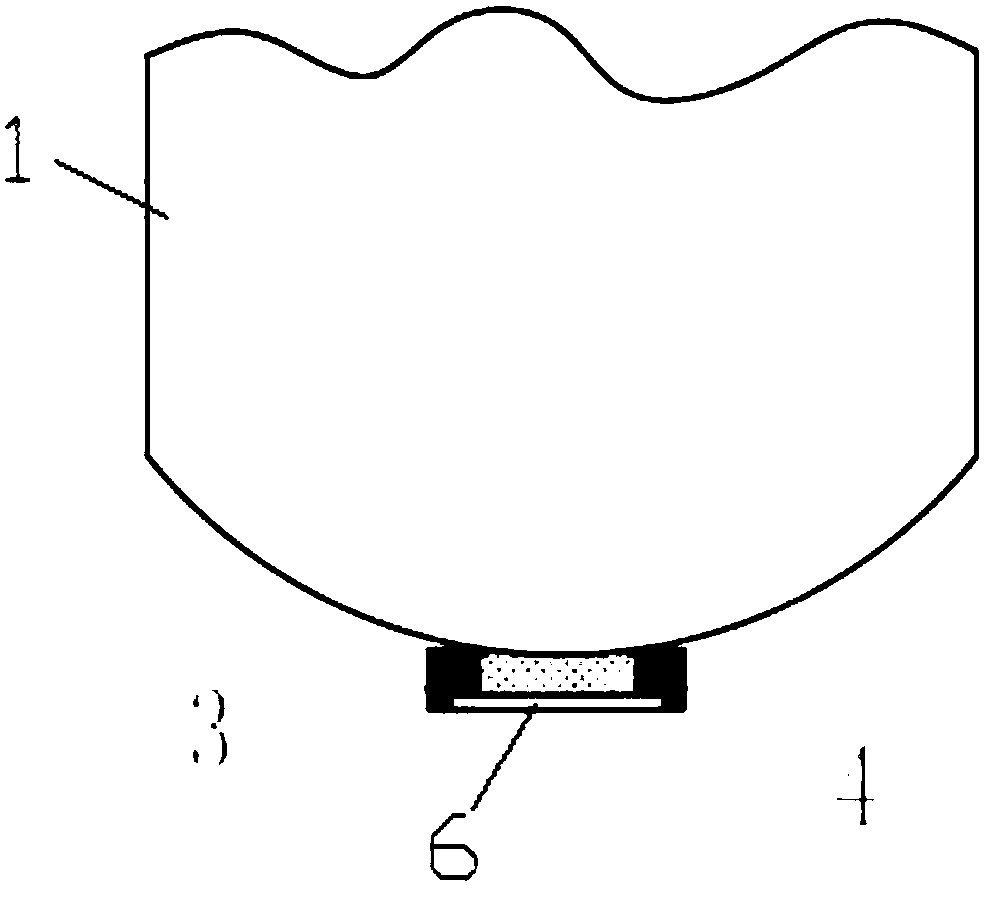

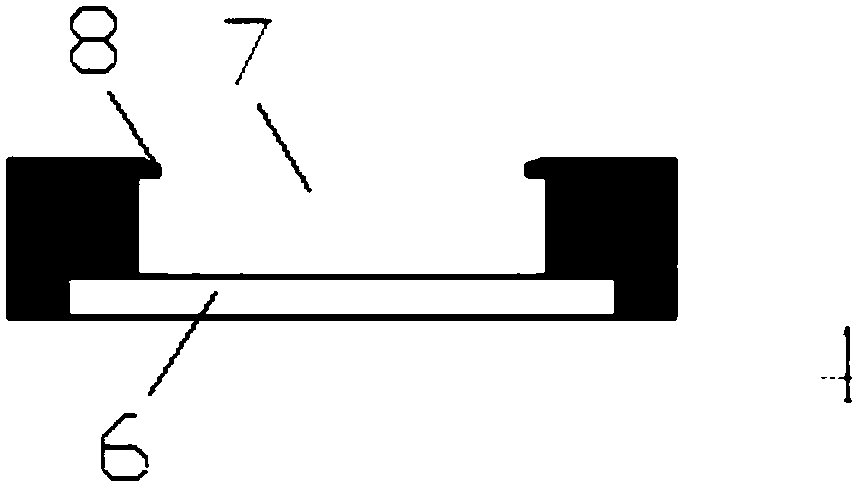

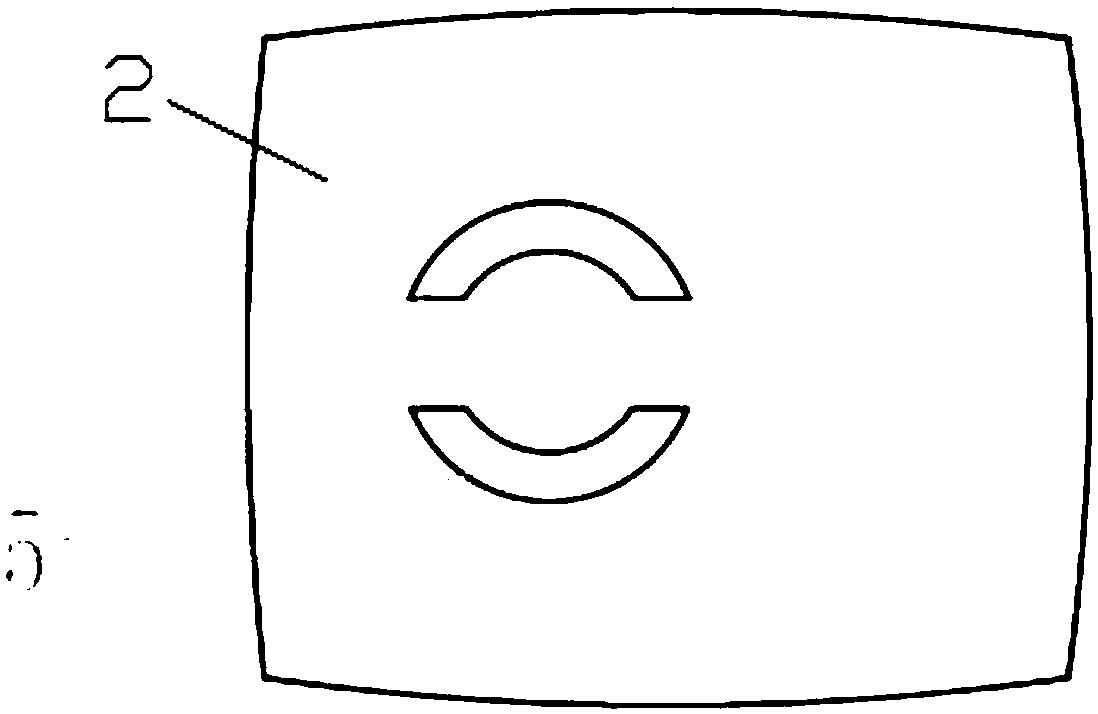

[0014] Such as Figure 1 to 3 As shown, a resin tank fixing structure of the present invention includes a resin tank 1 and a bottom bracket 4. The bottom of the resin tank 1 is provided with a rectangular boss 3, and the rectangular boss 3 and the upper part of the bottom bracket 4 are connected by a card slot. The card slot is arranged on the side of the rectangular boss 3, and the card slot is a horizontally arranged strip slot. The upper part of the bottom bracket 4 is provided with a square groove 7 that matches the rectangular boss 3, and the notch of the square groove 7 is provided with a hook 8 that matches the groove. A circular groove 6 is provided in the lower part of the bottom bracket 4. In order to stabilize the resin tank 1, the bottom plate 2 of the casing of the existing water softener is provided with an annular boss 5, and the circular groove 6 is exactly matched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com