Automobile front cover locking mechanism

A front cover and automobile technology, applied in the field of auto parts, can solve the problems of difficult adjustment, severe impact, and easy failure of the mechanism, and achieve the effects of convenient installation, high meshing strength and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

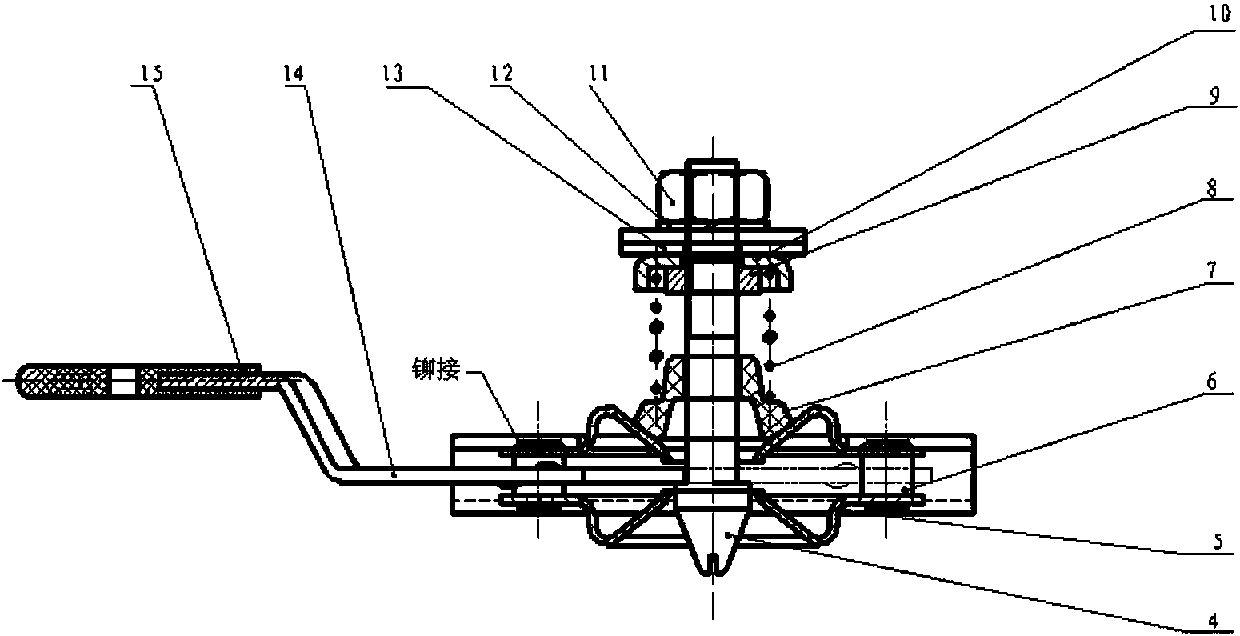

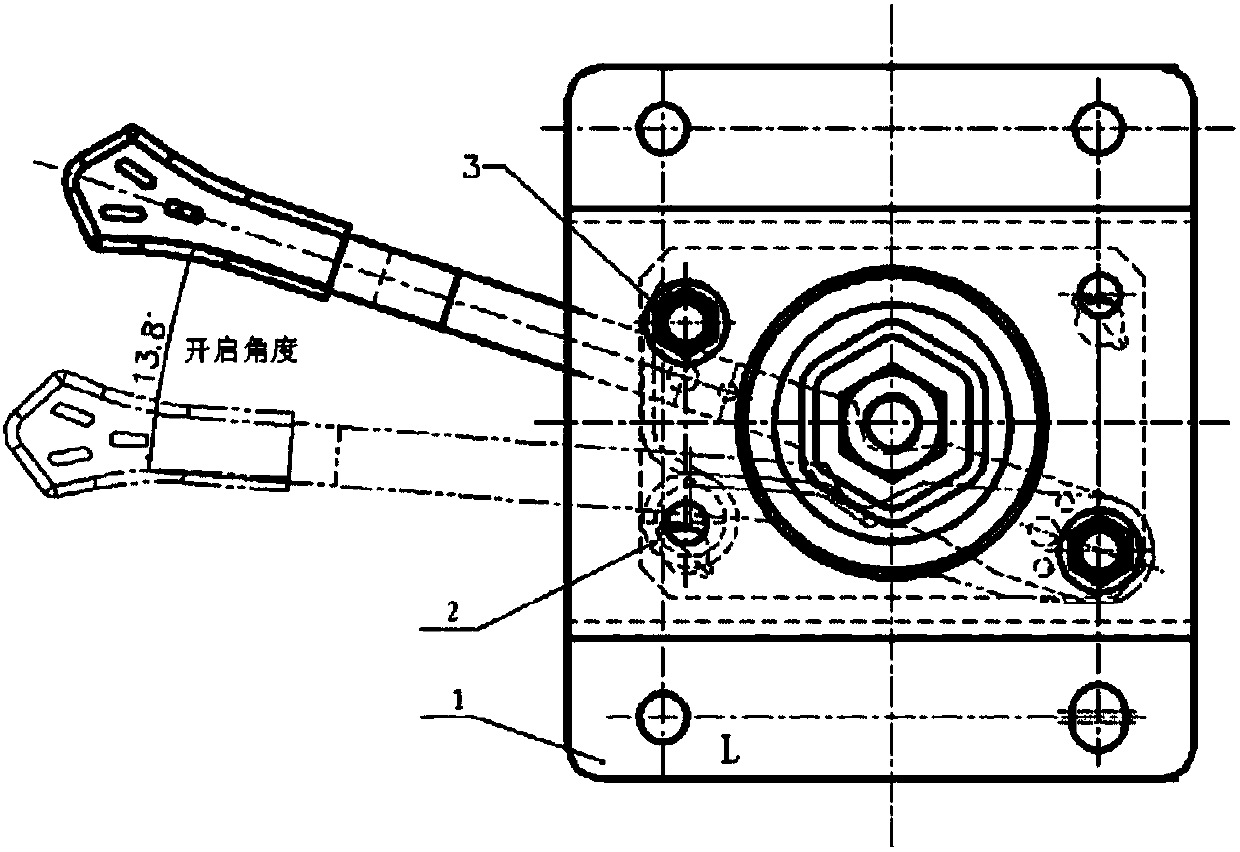

[0012] Such as figure 1 and figure 2 As shown, a car front cover lock mechanism includes a fixed plate 1, a spring 2, a tightening bolt 3, a fixed shaft 4, a cover plate 5, a positioning nut 6, a guide sleeve 7, a pressure spring 8, a concave welding nut 9, a reinforced version 10. Hex nut 11, spring washer 12, washer 13, opening rocker arm 14 and toggle arm 14; positioning nuts 6 are installed at the four corners of cover plate 5, riveted and fixed; spring 2 and opening rocker arm 14 are riveted On the cover plate 5, the cover plate 5 is installed on the fixed plate 1 through two obliquely symmetrical tightening bolts 3; the reinforcing plate 10 is set on the fixed sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com