High-efficiency and low-noise refrigeration compressor rotor

A refrigeration compressor, low-noise technology, applied in high-efficiency adjustment technology, mechanical equipment, machines/engines, etc., can solve problems such as differences in structure and function, compression efficiency, shock absorption and noise reduction effects, etc., to improve service life , reduce the force, increase the effect of exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, features and effects of the present invention, the following embodiments are exemplified and described in detail as follows in conjunction with the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

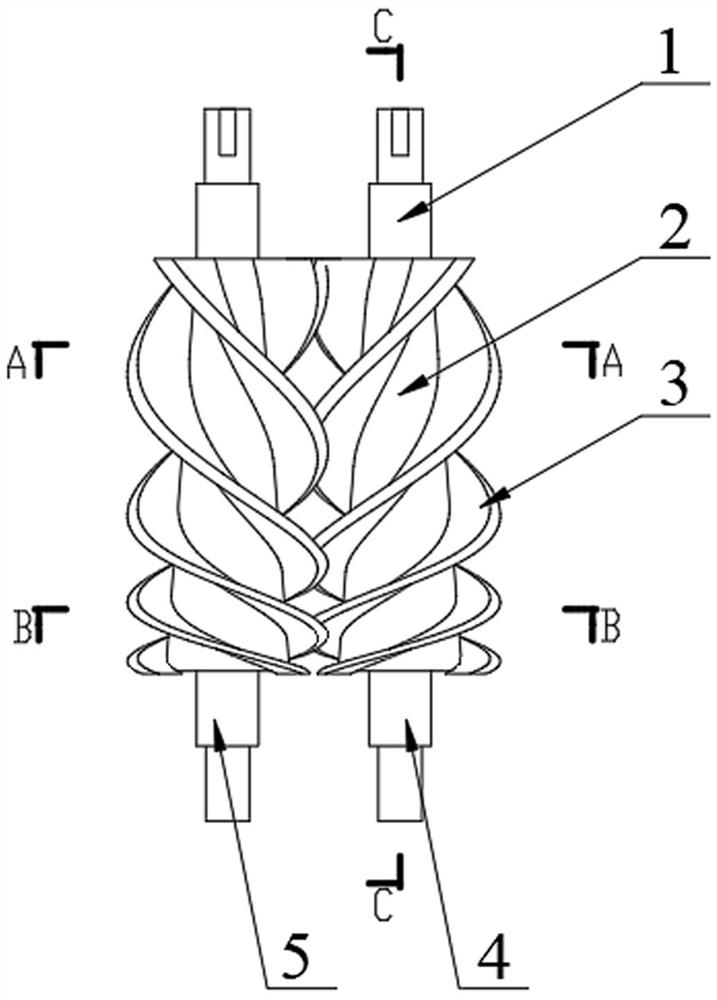

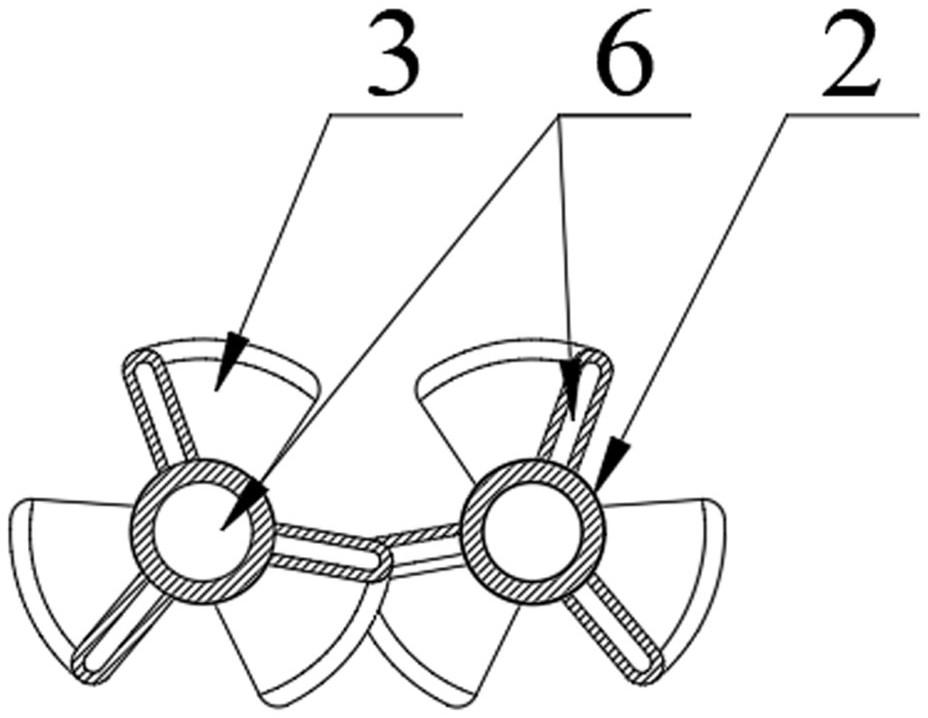

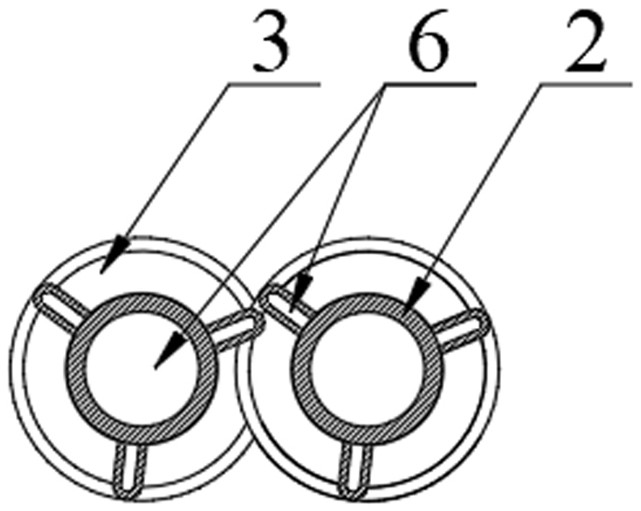

[0022] High-efficiency and low-noise refrigeration compressor rotor, the rotor includes a male rotor 4 and a female rotor 5 that are meshed and connected, wherein the middle sections of the male rotor and the female rotor are both air pressurized sections, and both ends of the male rotor and the female rotor are the same The shaft is fixed with a transmission connecting shaft 1, and the air pressurization section includes a central shaft 2 and a multi-channel helical blade 3 fixed on the outer circumference of the central shaft. The end of the rotor gradually increases in the direction of the exhaust end of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com