A dual oil circuit fuel nozzle flow test tool

A fuel nozzle and flow testing technology, which is applied to fuel injection devices, measuring devices, engine testing, etc., can solve the problems of mutual oil leakage between two oil passages, coaxiality and assembly errors, and inconsistent working conditions. Accurate flow, eliminate oil channeling, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation of the invention will now be described with reference to the drawings and specific examples, which are explanations of the invention rather than limitations.

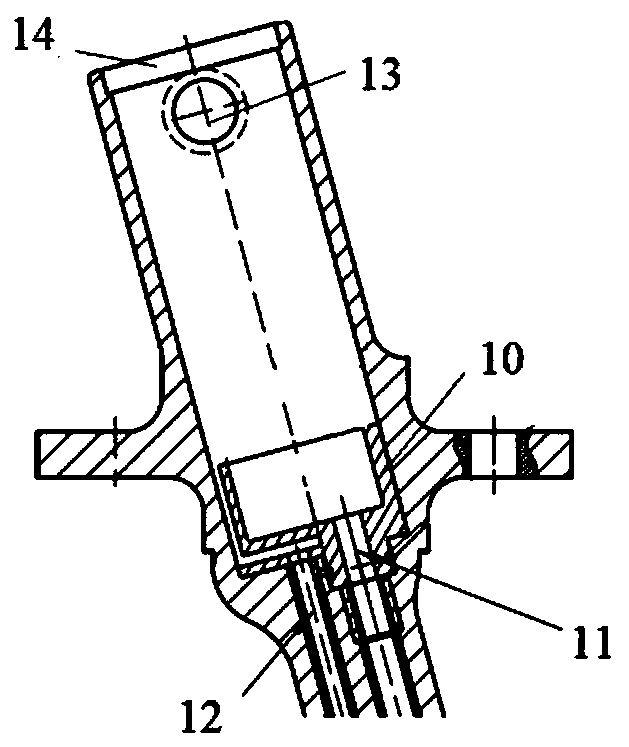

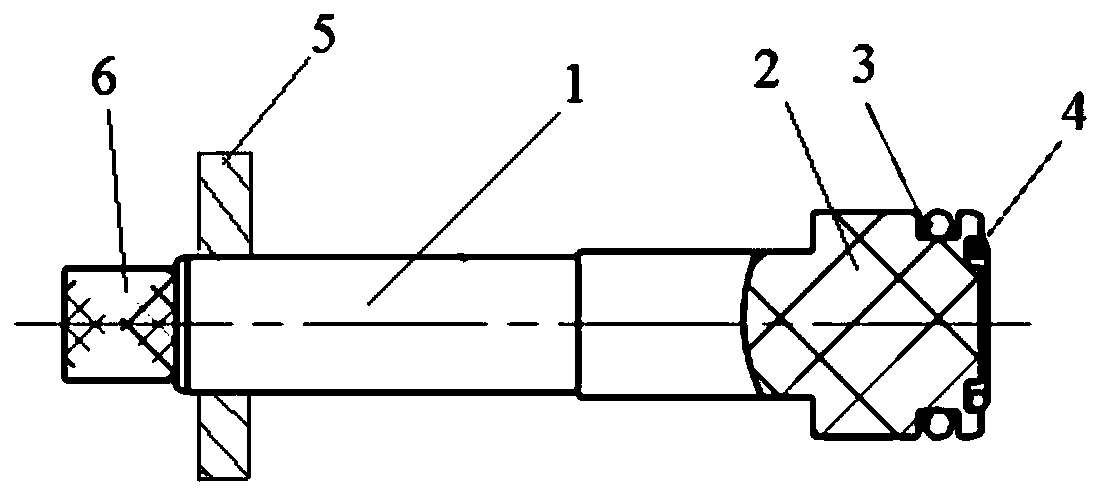

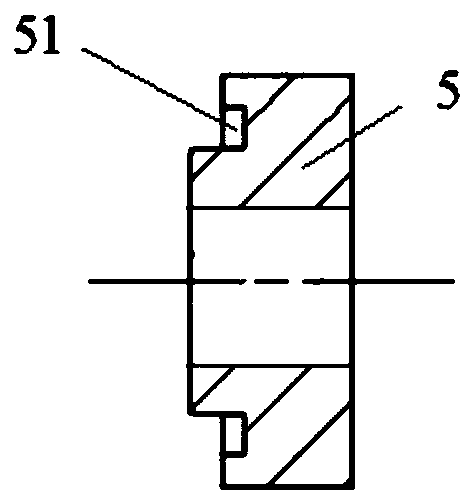

[0030] refer to figure 2 , a double oil circuit fuel nozzle flow test tool includes a mandrel 1, the upper part of the mandrel 1 is provided with a cover plate 5 for covering the hole 14 of the nozzle end cover, the upper end of the mandrel 1 is provided with a handle 6, and the handle 6 is provided with It has anti-slip knurling, which is convenient to hold when disassembling. The lower end of the mandrel 1 is provided with a plugging head 2 for inserting into the bottom cup assembly of the fuel nozzle to separate the shell and the first oil pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com