Bolt with self-locking function under vibration

A technology of bolts and functions, applied in the field of mechanical connectors, to achieve the effect of easy tightening of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

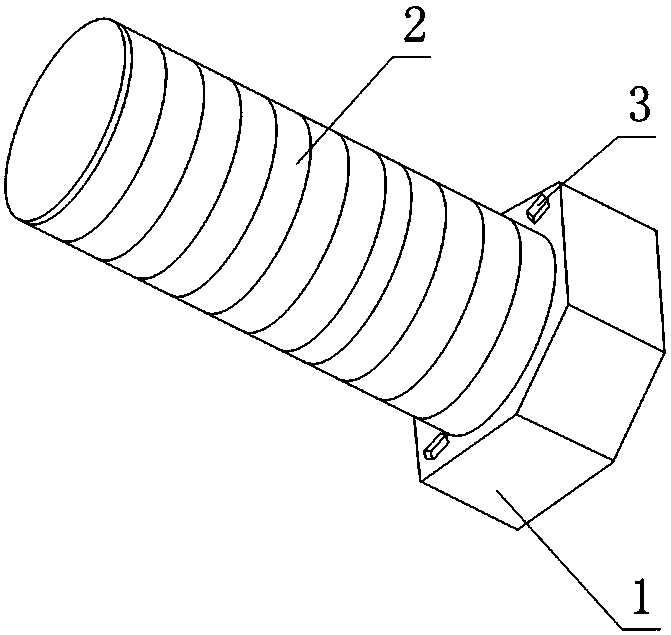

[0019] Such as figure 1 As shown, a bolt with self-loosening function under vibration includes a screw section and a nut end 1 arranged at the end of the screw section. The end surface of the nut end 1 close to the screw section is also provided with a plurality of elastic Protrusion 3, the elastic protrusion 3 can produce elastic deformation during the tightening process of the bolt; the free end of the elastic protrusion 3 is inclined toward the direction of loosening the bolt.

[0020] In this structure, the set screw section 2 has threads, which are used for threaded connection with the nut in the bolt connection to fasten the interconnected connectors. The above nut end 1 is used as the driving part for the operator to brake the rotation of the screw section 2 . In this structure, by setting the elastic protrusion 3 on the end surface of the nut end 1 close to the end of the screw section 2, in this way, during the tightening process of the bolt, the elastic protrusion 3...

Embodiment 2

[0023] Such as figure 1 As shown, this embodiment is further limited on the basis of embodiment 1: in order to make the above prestress evenly distributed in the circumferential direction of the bolt, the elastic protrusions 3 are evenly distributed in a ring shape relative to the axis of the screw segment.

[0024] As a further technical solution to make the above prestress evenly distributed in the circumferential direction of the bolt, the number of the elastic protrusions 3 is greater than three.

[0025] As a bolt form that is convenient for processing and manufacturing, the nut end 1, the screw rod section and the elastic protrusion 3 are an integral structure formed by casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com