Gear changeable structure of screw driver

A screwdriver, variable gear technology, applied in screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of long screwing operation, single function, inconvenient use, etc., and achieve the effect of easily tightening bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

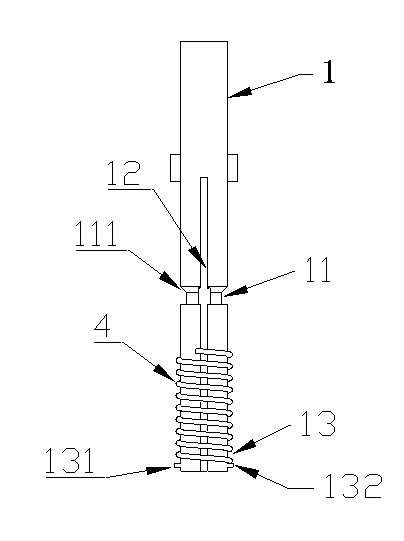

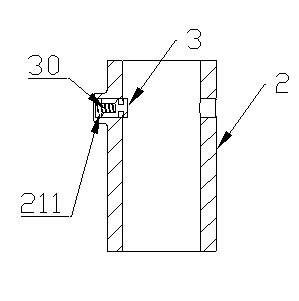

[0031] A variable gear structure for a screwdriver, comprising a first pipe and a second pipe, the first pipe is fixedly connected to the screwdriver, the second pipe is fixedly connected to the handle of the screwdriver, and the first pipe, the second The pipe piece, the screwdriver and the screwdriver handle are located on the same axis, and the second pipe piece can be fixed or movably connected to the first pipe piece to control the shifting of the screwdriver handle.

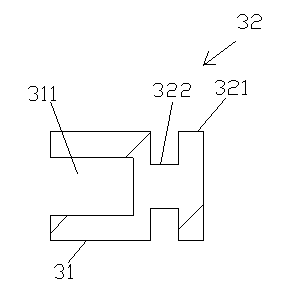

[0032] An elongated slot is provided on the outer surface of the first pipe part parallel to the axis, and a stopper is arranged inside the second pipe part, and the stopper can be fixed or movable in the elongated slot.

[0033] The first pipe member is provided with a plurality of annular neutral slots perpendicular to the axial direction, the elongated slots are vertically connected to the annular neutral slots, and the stopper can move circularly relative to the annular neutral slots.

[0034] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com