Novel rotary fast-assembly interface device

An interface device and rotary technology, which is applied to connecting components, camera bodies, optics, etc., can solve the problems of complicated installation and disassembly, inability to disassemble, worry about falling off, etc., to achieve simple and fast locking operation and high assembly efficiency. , the connection effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

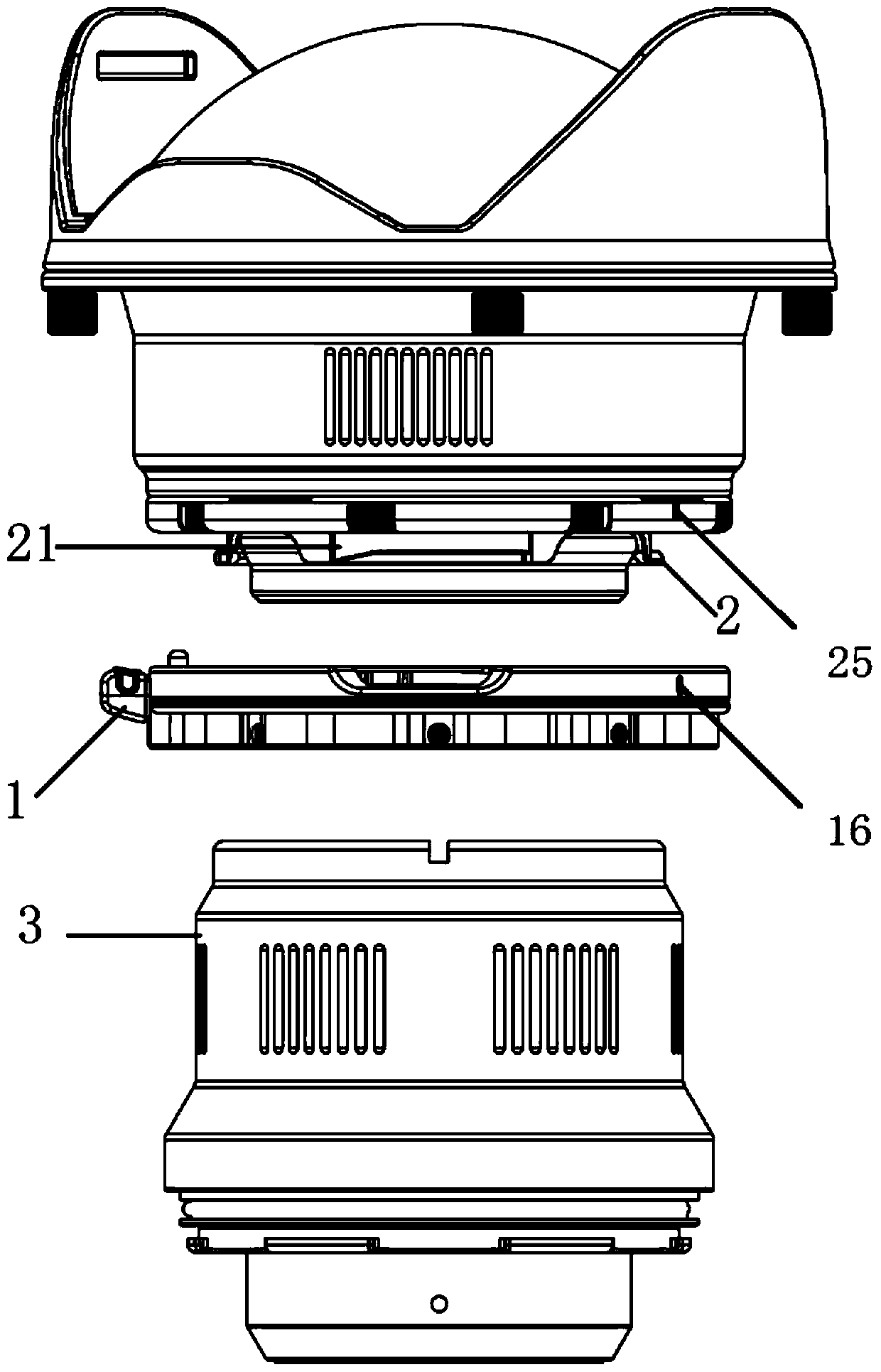

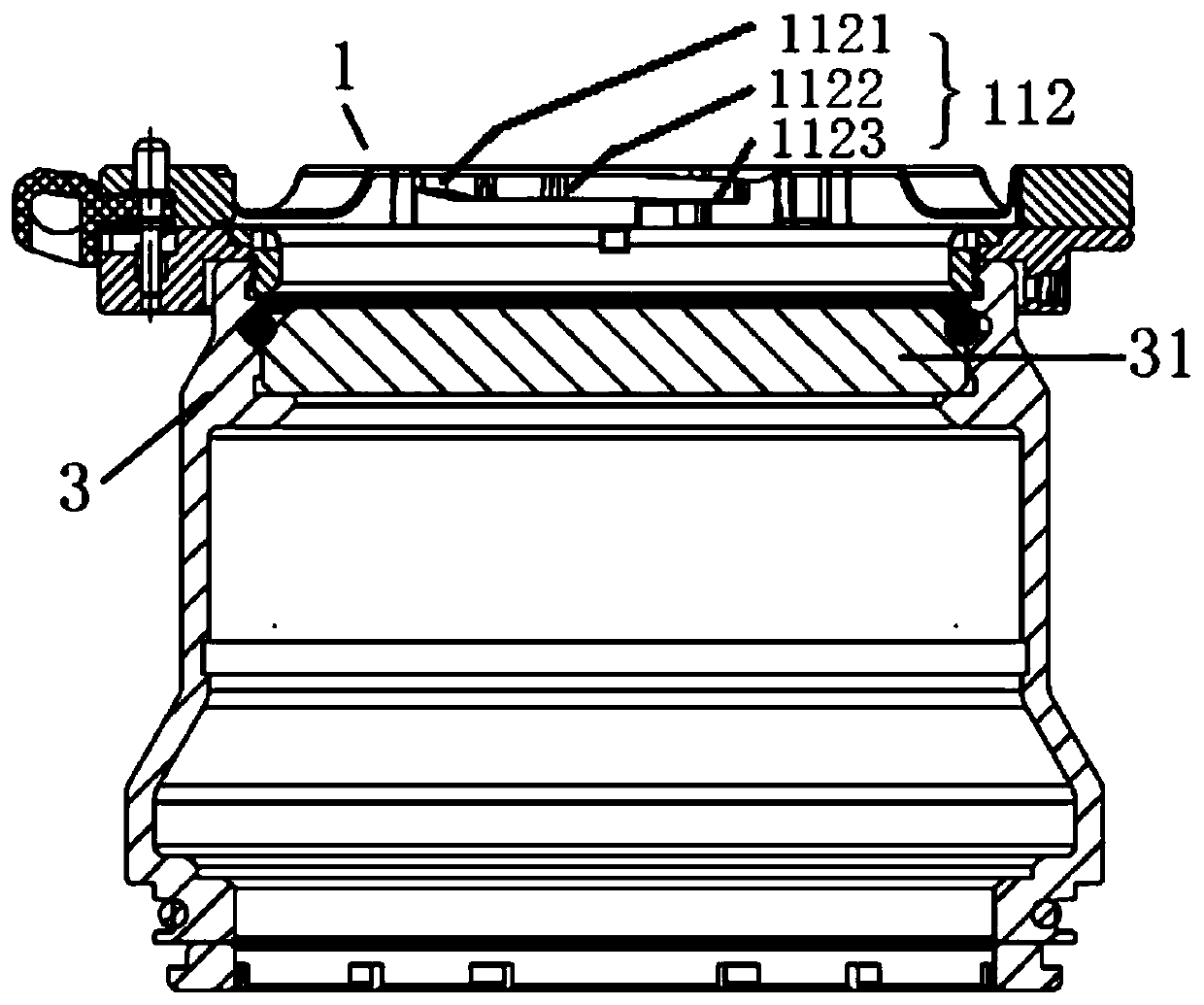

[0023] See figure 1 , The rotary quick-installation interface device of this embodiment is composed of a mounting base 1 and a connecting piece 2 . The connecting piece 2 is arranged on the image side of the conversion lens, and is integrally formed with the conversion lens or connected by screws or threads. The mounting base 1 is arranged on the object side of the visible window 31 of the waterproof lens barrel 3 , and is integrally formed with the waterproof lens barrel 3 or connected by threads. By installing the rotary quick-installation interface device formed by the female base 1 and the connecting piece 2, the conversion lens can be quickly and labor-savingly completed on the waterproof lens barrel 3.

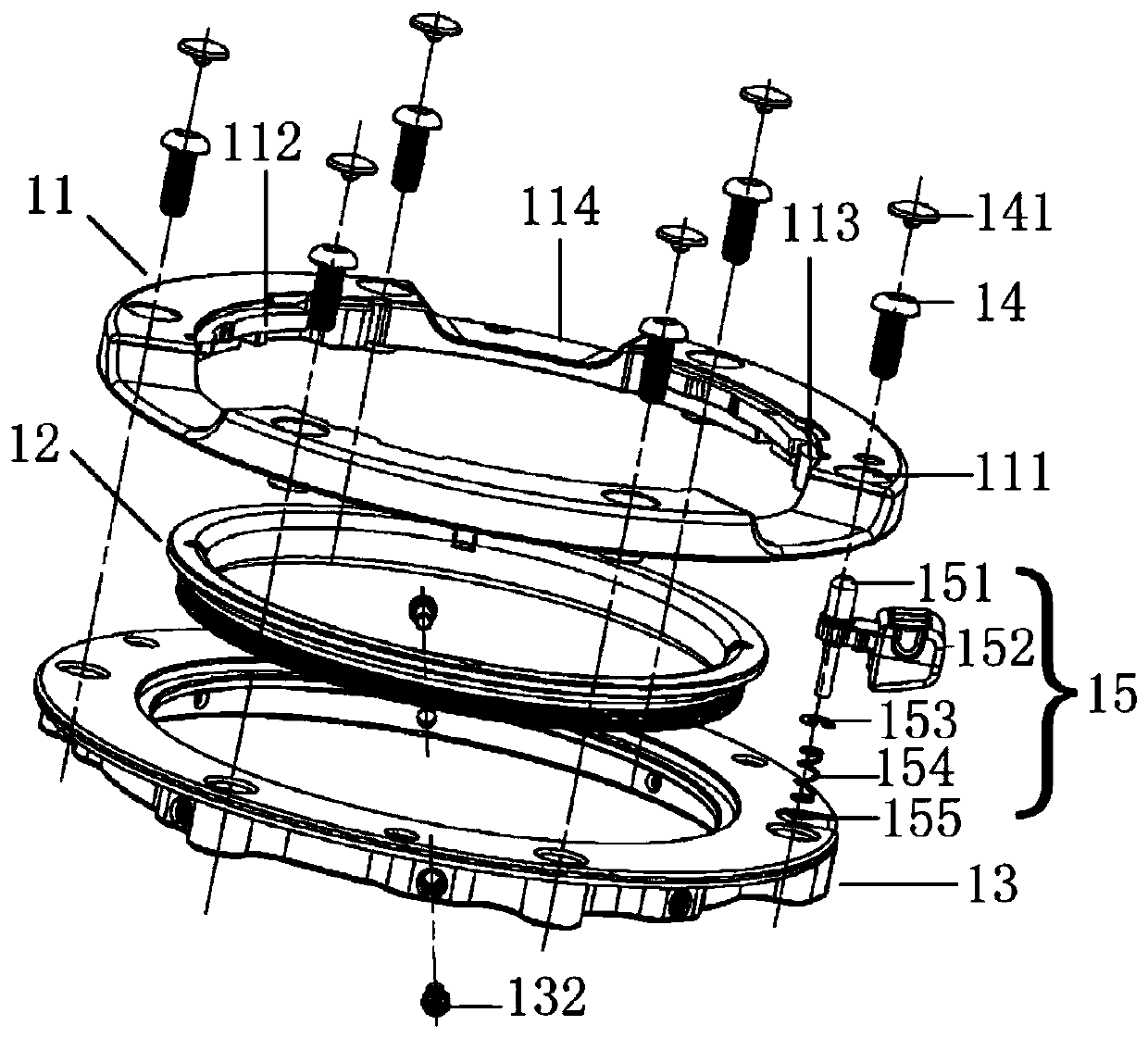

[0024] Specifically, see image 3 , the mounting base 1 is composed of a mounting base 11, a locking ring 12 and a base 13, the above three are all in the form of a ring, wherein, the mounting base 11 is provided with a number of mounting holes 111, and the number of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com