Friction type steel-concrete composite beam shear connecting key

A technology of connecting keys and section steel, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in guaranteeing construction quality, difficulty in meeting large demands, and difficulty in maintenance and repair, achieving good anti-loosening ability and shortening later replacement Or maintenance time, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

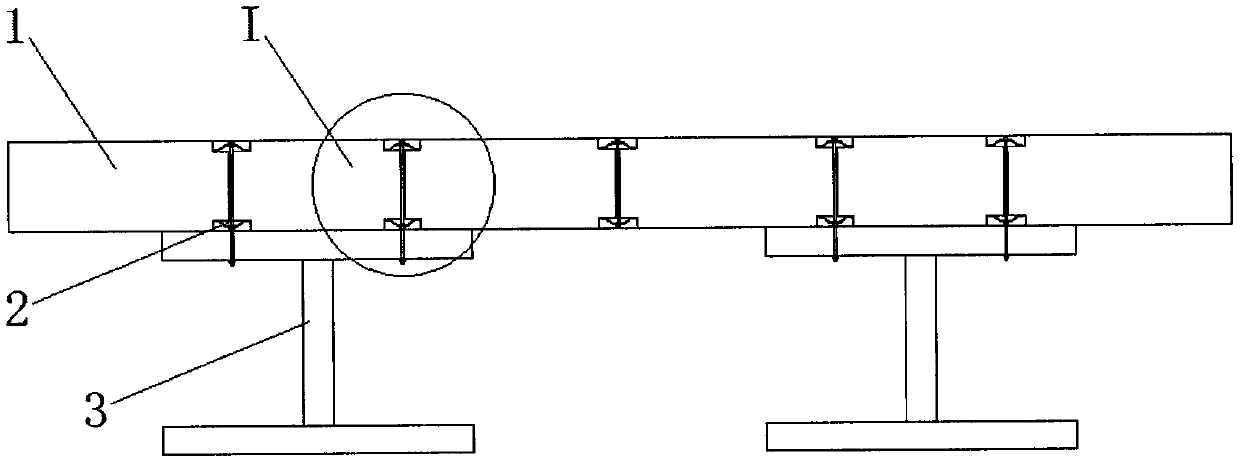

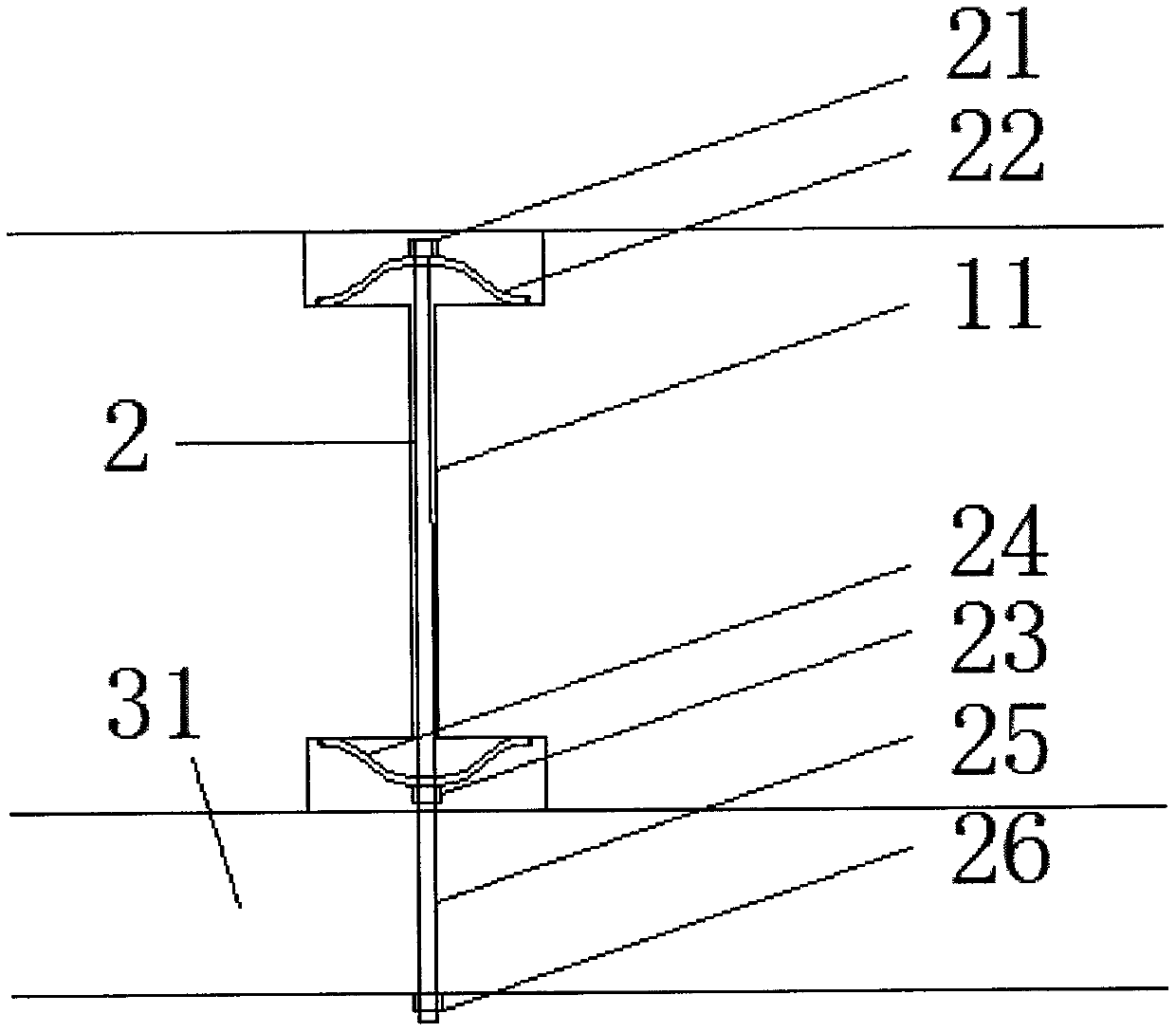

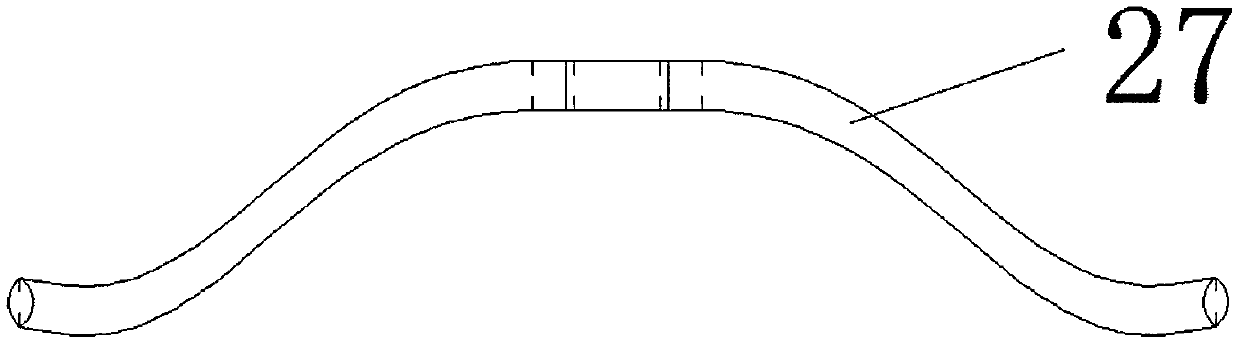

[0017] The invention provides a frictional steel-concrete composite girder shear connection key, which is characterized in that the shear force connection key comprises a prefabricated concrete bridge deck 1 , prestressed high-strength bolts 2 and a steel girder 3 . A number of cylindrical holes 11 are distributed on the precast concrete bridge deck. The upper part of the prestressed high-strength bolts 2 is connected with the precast concrete bridge deck 1 through the holes 11. The lower part of the prestressed high-strength bolts 2 is connected to the upper flange of the steel girder 3. 31 through connection; the joints between the prestressed high-strength bolts 2 and the upper and lower surfaces of the precast concrete bridge deck 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com