Intelligent spare part storing and taking device

A technology for spare parts and access devices, applied in storage devices, transportation and packaging, etc., can solve the problems of slowing down repair time, reducing repair efficiency, shortening the service life of electronic spare parts, etc. The effect of improving storage efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

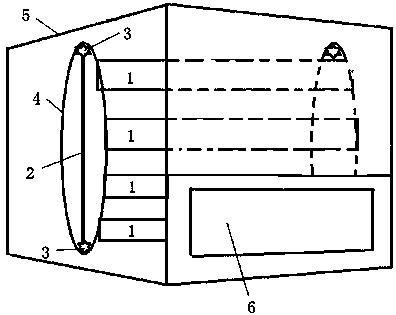

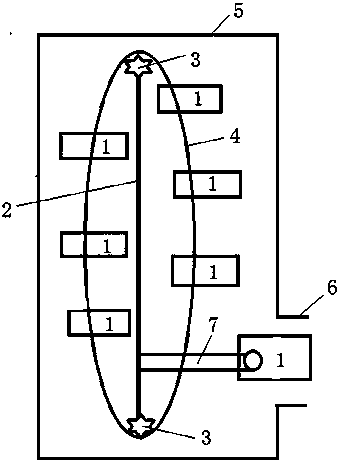

[0016] The following combination Figure 1 ~ Figure 2 , the technical content, structural features, achieved goals and effects of the present invention will be described in detail through preferred embodiments.

[0017] Such as figure 1 with figure 2 As shown, the intelligent spare parts access device provided by the present invention includes: a controller (not shown in the figure); a bracket 2 arranged vertically; a vertical rotary drive fixedly arranged on the bracket 2, and It is connected with the controller through a circuit, and under the control of the controller, it performs a vertical rotary motion around the support 2; a plurality of bins 1 are used to store spare parts inside, and each bin 1 is arranged on the vertical On the slewing drive, it follows the vertical slewing drive to carry out the slewing motion in the vertical direction; wherein, the controller is used to distribute and record the category and weight of the spare parts stored in each bin 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com