Cloth winding machine convenient to operate

A cloth rolling machine and cloth rolling roller technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of cumbersome operation and complex structure of the cloth rolling machine, and achieve simple and convenient operation, simple structure, The effect of ensuring the quality of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

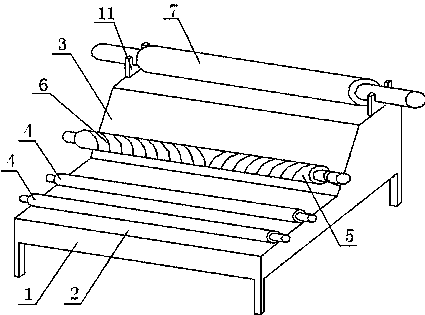

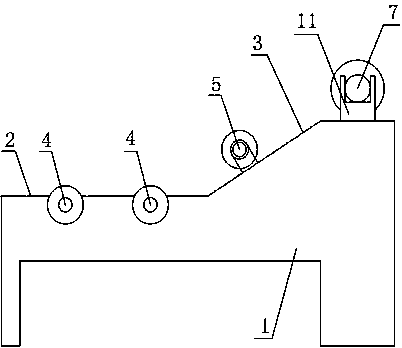

[0019] Such as figure 1 and figure 2 The cloth rolling machine shown is easy to operate, including a frame 1, a plane 2 is provided on the frame 1, and a slope 3 inclined upward from the plane 2, and at least two planes 2 are provided on the plane 2 of the frame 1 A first cloth guide roller 4, the second cloth guide roller 5 is arranged on the slope 3 of the frame 1, and the first cloth guide roller 4 and the second cloth guide roller 5 are all parallel to the plane 2 and the slope 3 intersection line, the second cloth guide roller 5 is provided with an anti-slip ring 6; the top of the inclined surface 3 is provided with a cloth rolling roller 7, and the first cloth guide roller 4 rotates toward the direction that the top is close to the inclined surface 3, and the The second cloth guide roller 5 rotates in the same direction as the first cloth guide roller 4, and the cloth roll 7 rotates in the opposite direction to the first cloth guide roller 4; Two "female" holders 11 a...

Embodiment 2

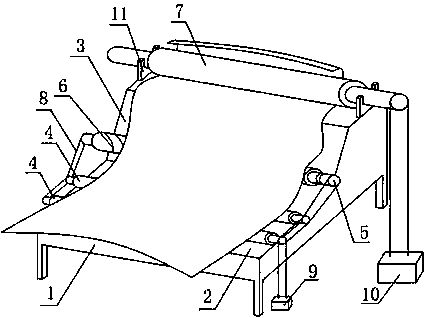

[0021] Such as image 3 The cloth rolling machine shown is easy to operate, on the basis of Embodiment 1, the first cloth guide roller 4 and the second cloth guide roller 5 are linked by a belt 8; the first cloth guide roller 4, the second cloth guide roller The cloth roller 5 is driven by a first motor 9 , and the cloth winding roller 7 is driven by a second motor 10 ; the first motor 9 and the second motor 10 rotate at the same speed. Since the second cloth guide roller 5 and the first cloth guide roller 4 rotate in the same direction, the first cloth guide roller 4 and the second cloth guide roller 5 are linked through the belt 8, so that the two sets of cloth guide rollers can move synchronously , further simplify the structure of the present invention, and facilitate the user to control the cloth guide roller. The first cloth guide roller 4 and the second cloth guide roller 5 are driven by a first motor 9, and the cloth winding roller 7 is driven by a second motor 10; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com