Control method of side guide plate of hot-rolling coiler

A control method and side guide plate technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems affecting operating efficiency and achieve the effects of improving operating efficiency, reducing wear, and reducing replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

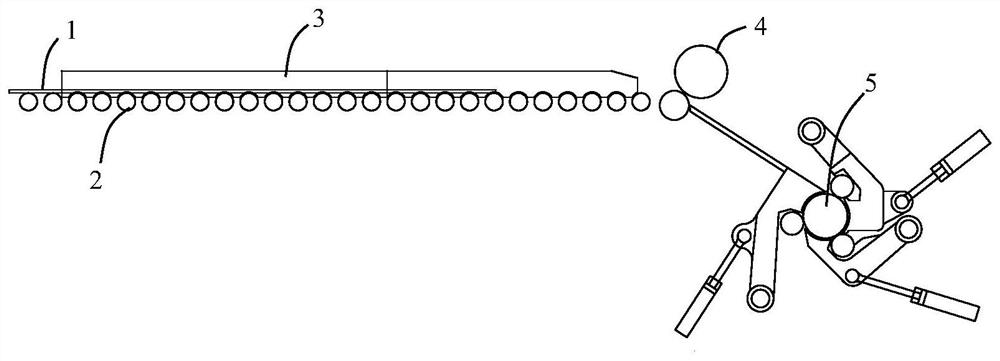

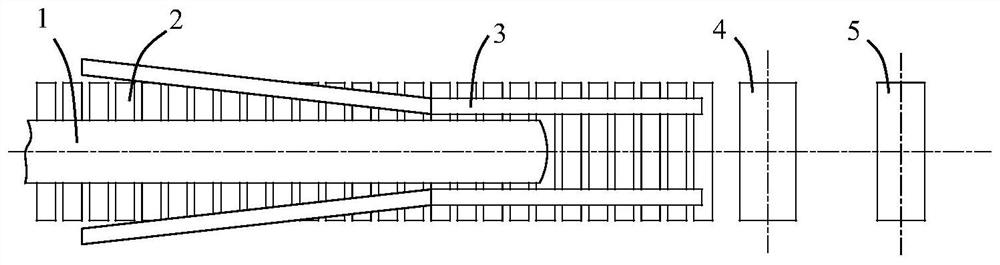

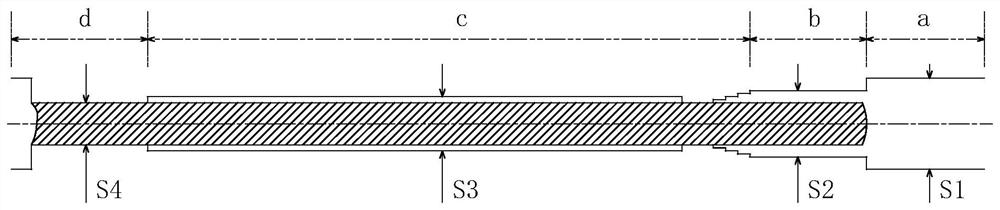

[0044] Such as image 3 Shown, the control method of the side guide plate of the hot rolling coiler of the present invention is as follows:

[0045] (1) Belt threading stage: the control unit controls the opening degree adjustment mechanism of the side guide plate to adjust the opening degree of the side guide plate to the first opening degree S 1 ,

[0046] S 1 =B+W+B 1 ,

[0047] where S 1 is the first opening, that is, the opening of the side guide plate in the belt threading stage,

[0048] B is the strip width,

[0049] W is the short-stroke opening of the side guide plate,

[0050] B 1 add value to standby;

[0051] The strip threading stage refers to the stage from when the head of the strip exits the finishing stand to when the head bites into the pinch roller. see image 3 In part a, the side guide plate mainly plays a guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com