High-strength hydrolysis-resistant nylon wheel hub-free fan material and preparation method thereof

A hydrolysis-resistant, high-strength technology, applied in the field of auto parts, can solve the problems of floating fibers on the surface and poor hydrolysis resistance, and achieve good performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

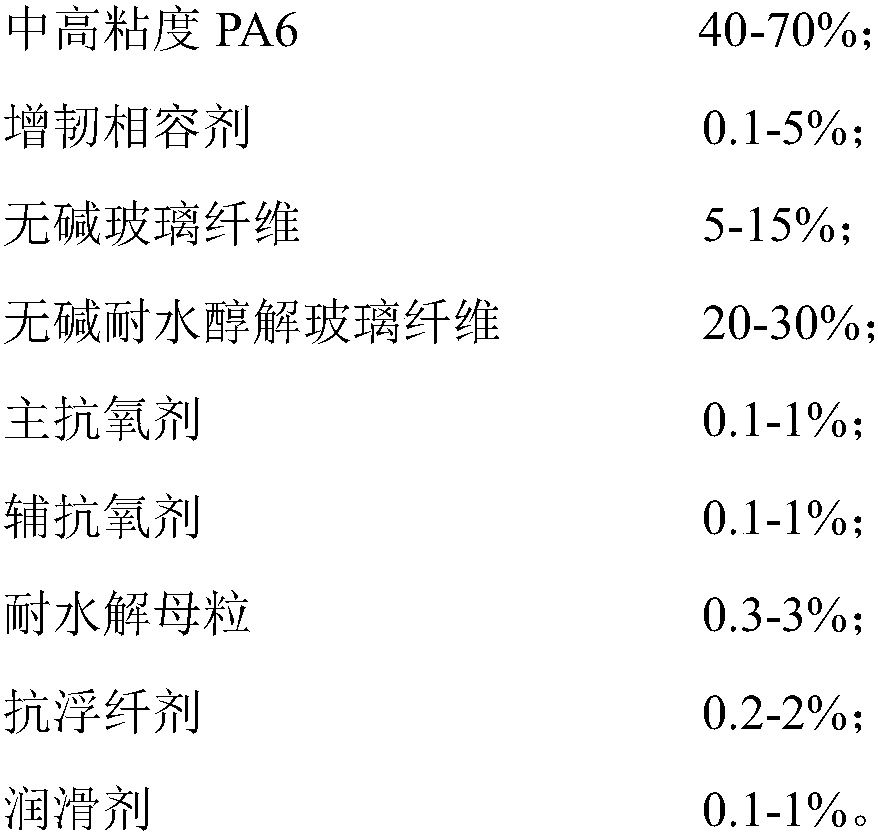

[0028] This embodiment provides a high-strength hydrolysis-resistant nylon hubless fan material, which consists of the following components by mass percentage:

[0029]

[0030] The preparation method is as follows:

[0031] (1) Add a silane coupling agent to the nylon base material containing additives according to 1% of the base material mass for coupling treatment, and send it to an electronic weight loss scale;

[0032] (2) the toughening compatibilizer is sent into another electronic weight loss scale and the nylon base material after the coupling treatment is blanked respectively in a ratio of 5%:95%, and glass fiber (including Alkali-free glass fiber and non-alkali hydroalcolysis-resistant glass fiber) blending extrusion granulation,

[0033] The rotational speed of the twin-screw machine is 300 rpm, and the temperature is 235° C., thereby obtaining a high-strength hydrolysis-resistant nylon hubless fan material.

[0034] Mechanical Properties of Materials

[0035...

Embodiment 2

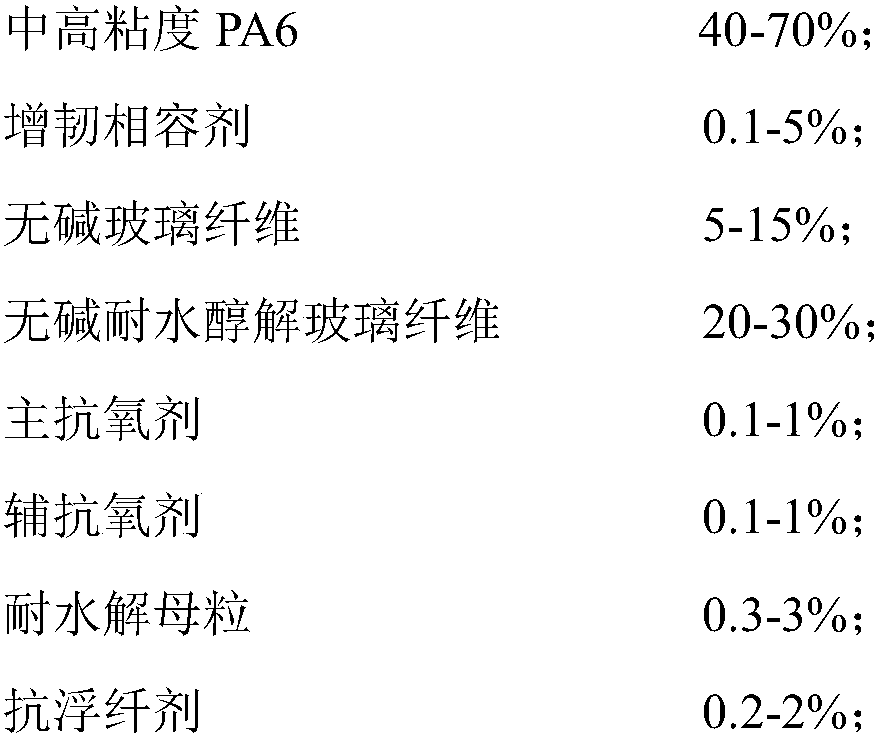

[0038] This embodiment provides a high-strength hydrolysis-resistant nylon hubless fan material, which consists of the following components by mass percentage:

[0039]

[0040] The preparation method is as follows:

[0041] (1) Add a silane coupling agent to the nylon base material containing additives according to 2% of the base material mass for coupling treatment, and send it to an electronic weight loss scale;

[0042] (2) the toughening compatibilizer is sent into another electronic weight loss scale and the nylon base material after the coupling treatment is blanked respectively in a ratio of 10%:90%, and glass fiber (including Alkali-free glass fiber and non-alkali hydroalcolysis-resistant glass fiber) blending extrusion granulation,

[0043] The rotational speed of the twin-screw machine is 350 rpm, and the temperature is 255° C., thereby obtaining a high-strength hydrolysis-resistant nylon hubless fan material.

[0044] Mechanical Properties of Materials

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com