A kind of functionalized polyurethane and its preparation method and application

A polyurethane and functionalized technology, applied in the field of functionalized polyurethane and its preparation, can solve the problems of reduced mechanical properties, limited application, creep and the like, and achieves the effects of good creep resistance, simple method and good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1

[0037] Embodiment 1 one-step method solvent polymerization

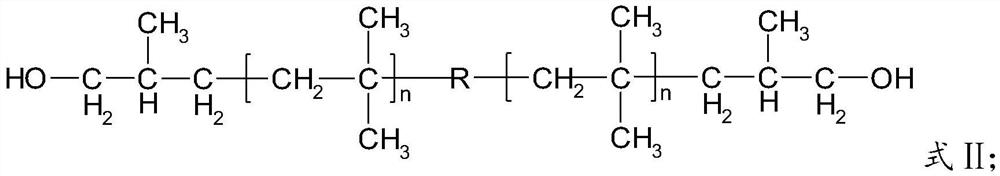

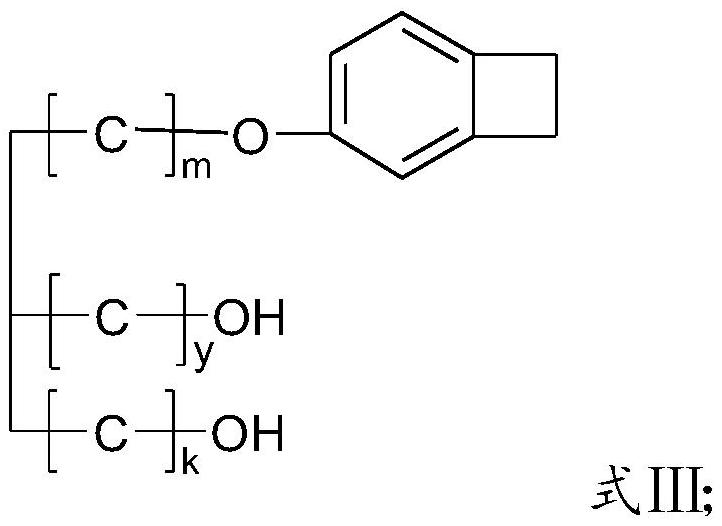

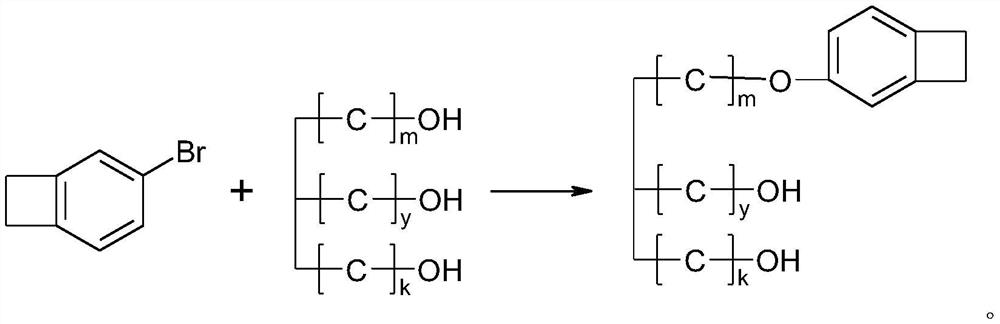

[0038] Add 400ml of tetrahydrofuran / N,N-dimethylacetamide (volume ratio 1:6) solvent, 30g polycarbonate diol (polycarbonate containing 1,6-hexanediol in Ube, Japan) into the four-necked bottle UH-CARB50 (molecular weight 500)) and 30g polyisobutylene glycol (molecular weight 1000), stir, be warmed up to 70 ℃; Add chain extender 10g ethylene glycol and 10g 4-benzocyclobutenyl glycol (m= 1, y=1, k=1), fully stirred to completely dissolve the reactant; then add 20g of 4,4'-diphenylmethane diisocyanate (MDI), heat up to 100°C, react for 6 hours, stop stirring, Cool to obtain a polyurethane solution with a solid content of about 25%.

Embodiment 2 1

[0039] Embodiment 2 one-step method solvent polymerization

[0040] Add 400ml of tetrahydrofuran / N,N-dimethylacetamide (volume ratio 1:6) solvent, 30g polycarbonate diol (polycarbonate containing 1,6-hexanediol in Ube, Japan) into the four-necked bottle UH-CARB200 (molecular weight 2000)) and 30g polyisobutylene glycol (molecular weight 2000), stir, be warmed up to 70 ℃; Add chain extender 10g butanediol and 10g 4-benzocyclobutenyl glycol (m= 1, y=1, k=1), fully stirred to completely dissolve the reactants; then add 20g of 4,4'-diphenylmethane diisocyanate (MDI), heat up to 100°C, react for 6 hours, stop stirring, Cool to obtain a polyurethane solution with a solid content of about 26%.

Embodiment 3

[0041] Embodiment 3 Two-step method solvent polymerization

[0042]Add 400ml N, N-dimethylacetamide solvent, 30g polycarbonate diol (Japanese Ube polycarbonate UH-CARB100 (molecular weight 1000) containing 1,6-hexanediol) and 30g Polyisobutylene diol (molecular weight 1000), stir, heat up to 70°C, fully dissolve; add 20g of 4,4'-diphenylmethane diisocyanate (MDI) to react for 60 minutes, measure the isocyanate content during the reaction, in Add 10g of ethylene glycol and 10g of 4-benzocyclobutenyl diol (m=1, y=1, k=1) when the isocyanate group is reduced to the theoretical amount, add the chain extender and then react for 5 hours, stop Stir and cool to obtain a polyurethane solution with a solid content of about 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com