Non-contact type corner box

A non-contact, corner box technology, applied in the field of conveying machinery, can solve the problems of conveying scraper and conveying pipeline wear, increase working resistance, and occupy small space, so as to ensure stable and reliable work, service life, and clear positional relationship Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

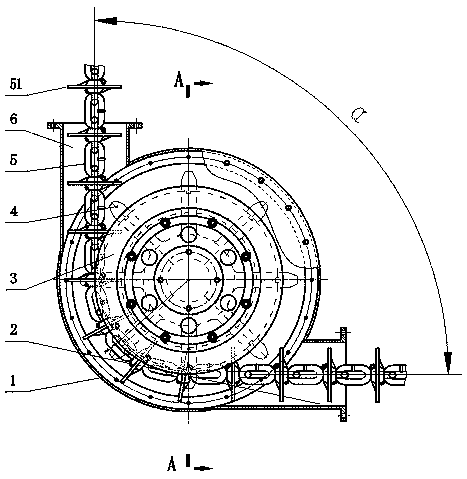

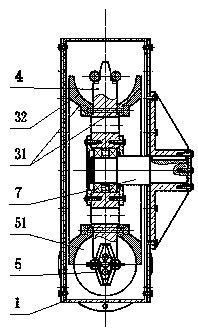

[0015] exist figure 1 and figure 2 In the non-contact corner box shown, the box shell 1 is a circular shell member, and the tube chain sprocket 4 corresponding to the tube chain 5 is arranged in the box shell 1, and the tube chain sprocket 4 passes through the bearing The rotation is supported on the sprocket shaft 7, the sprocket shaft 7 is fixedly connected to the shaft seat, and the shaft seat is fixedly connected to the box shell 1, so that the pipe chain sprocket 4 is rotatably supported on the box shell 1 through the sprocket shaft 7; the box shell 1 Feed pipe 6 and discharge pipe 2 are arranged on the circumference of the pipe chain 5, the feed pipe 6 and discharge pipe 2 are circular pipes corresponding to the circular scraper 51 on the pipe chain 5, the feed pipe 6 and the discharge pipe 2 The extended end of the feed pipe 2 is provided with a connecting flange connected to the conveying pipeline; the center line of the feed pipe 6 and the center line of the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com