Cutting circular saw

A circular saw and saw blade technology, applied in the field of electric tools, can solve the problems of blocking sight, easy shaking, low processing accuracy, etc., and achieve the effect of reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

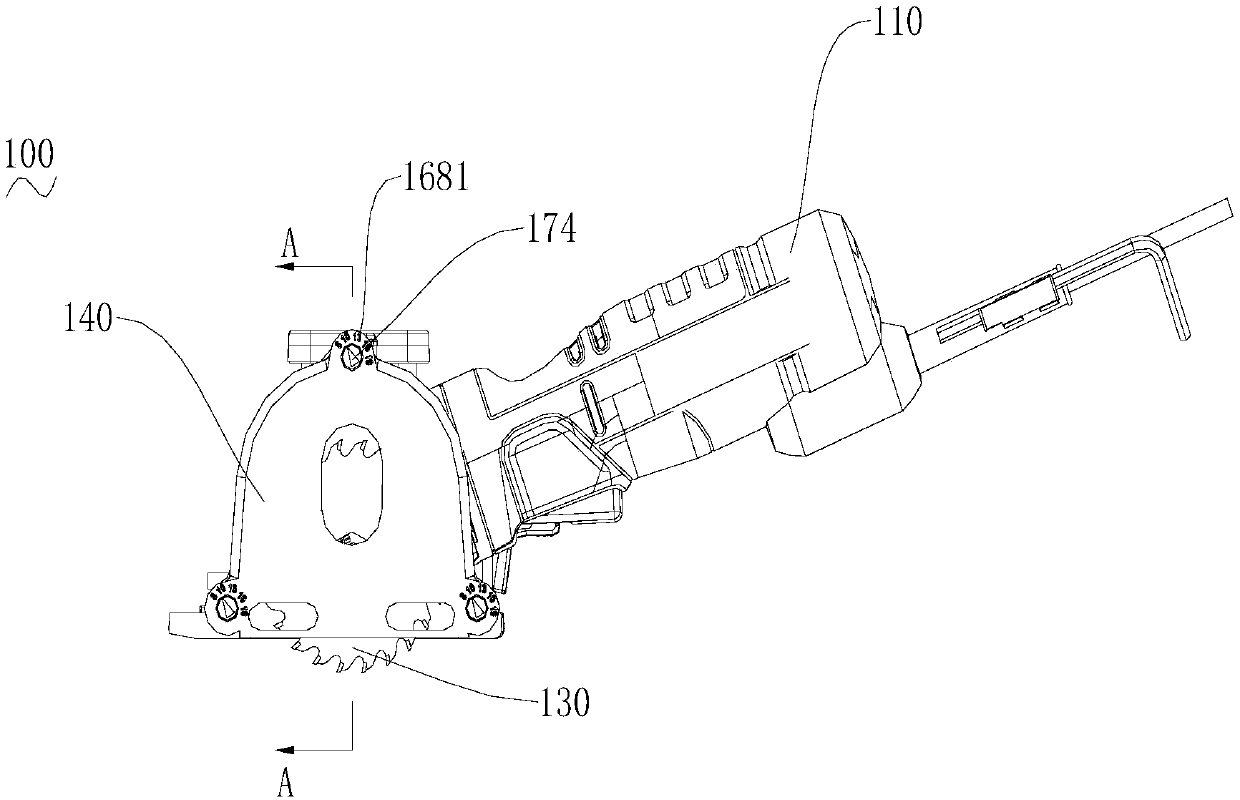

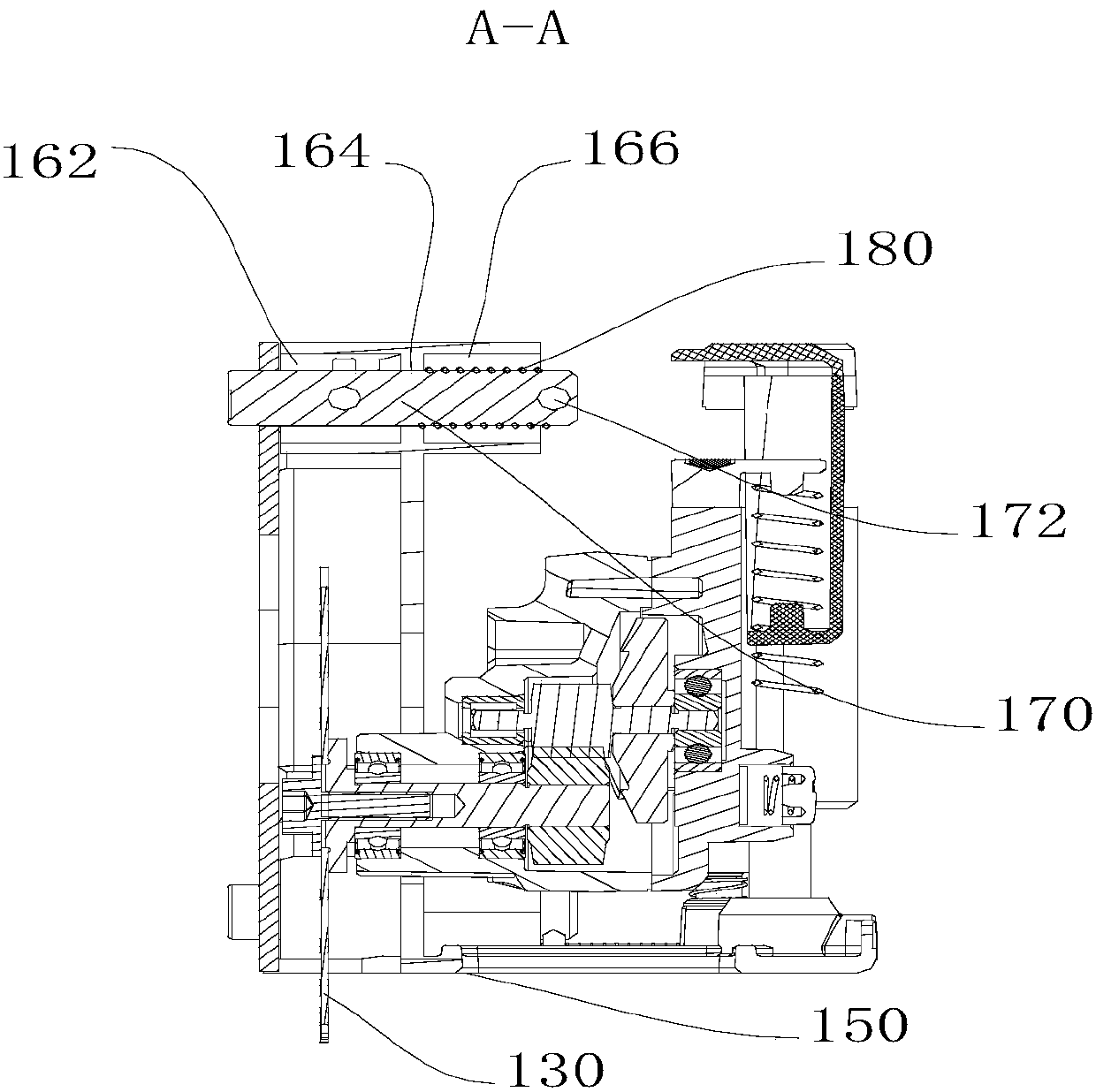

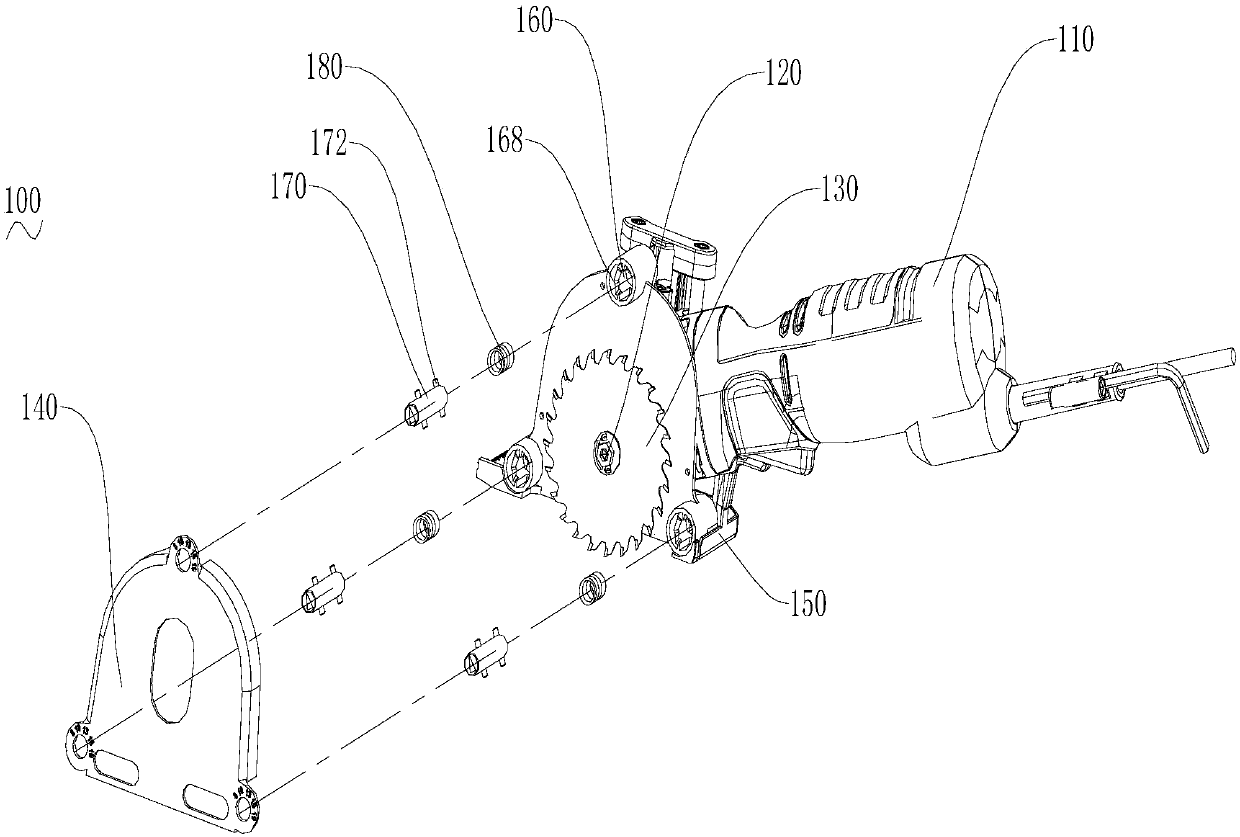

[0035] The cutting circular saw of the present invention comprises a casing 110, a motor is installed in the rear casing of the casing 110, a transmission mechanism and an output shaft 120 are installed in the front casing, and a saw blade 130 is installed on the output shaft 120, for To eliminate potential safety hazards, a shield 140 covering the saw blade 130 is also installed on the casing 110 . The front bottom of the casing 110 has a base 150, and the base 150 is provided with a through hole for the saw blade 130 to pass through. When cutting, the operator operates the circular saw so that the saw blade 130 is exposed downward from the through hole of the base, and the motor The output shaft 120 is driven to rotate through the transmission mechanism, and the saw blade 130 is driven to rotate for cutting.

[0036] The casing 110 is equipped with a distance adjustment device that can extend out of the casing parallel to the output shaft 120 and beyond the outer surface of ...

Embodiment 2

[0049] Such as Figure 5 As shown, a cutting circular saw includes a casing 110, an output shaft and a power drive device for driving the output shaft to rotate are arranged in the casing, a saw blade 130 is installed on the output shaft, and a saw blade 130 is arranged on the casing. There is a base 150 at the front bottom of the casing 110, and the base 150 is provided with a through hole for the saw blade 130 to pass through. When cutting, the operator operates the circular saw to make the saw blade 130 pass through the through hole of the base The center is exposed downward, and the motor drives the output shaft to rotate through the transmission mechanism, driving the saw blade 130 to rotate for cutting.

[0050] The cutting circular saw is equipped with a distance adjusting device that can extend parallel to the output shaft outside the casing, exceed the outer surface of the shield and be positioned. This distance adjusting device is a runner 190 installed on the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com