Goods allocation optimization method applied to Flying-V untraditional layout warehouse

A technology of storage space allocation and optimization method, which is applied in the field of warehouse management, and can solve problems such as defects in the storage space allocation of Flying-V-shaped layout warehouses that cannot be effectively solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

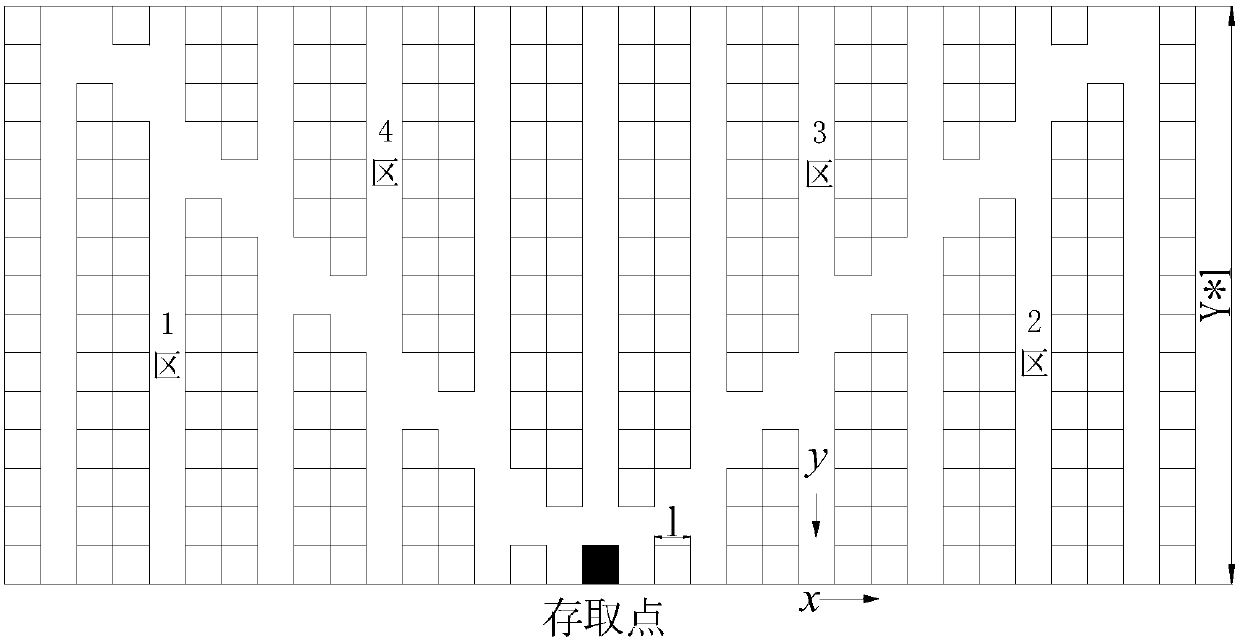

[0084] Below in conjunction with accompanying drawing, the present invention will be further described.

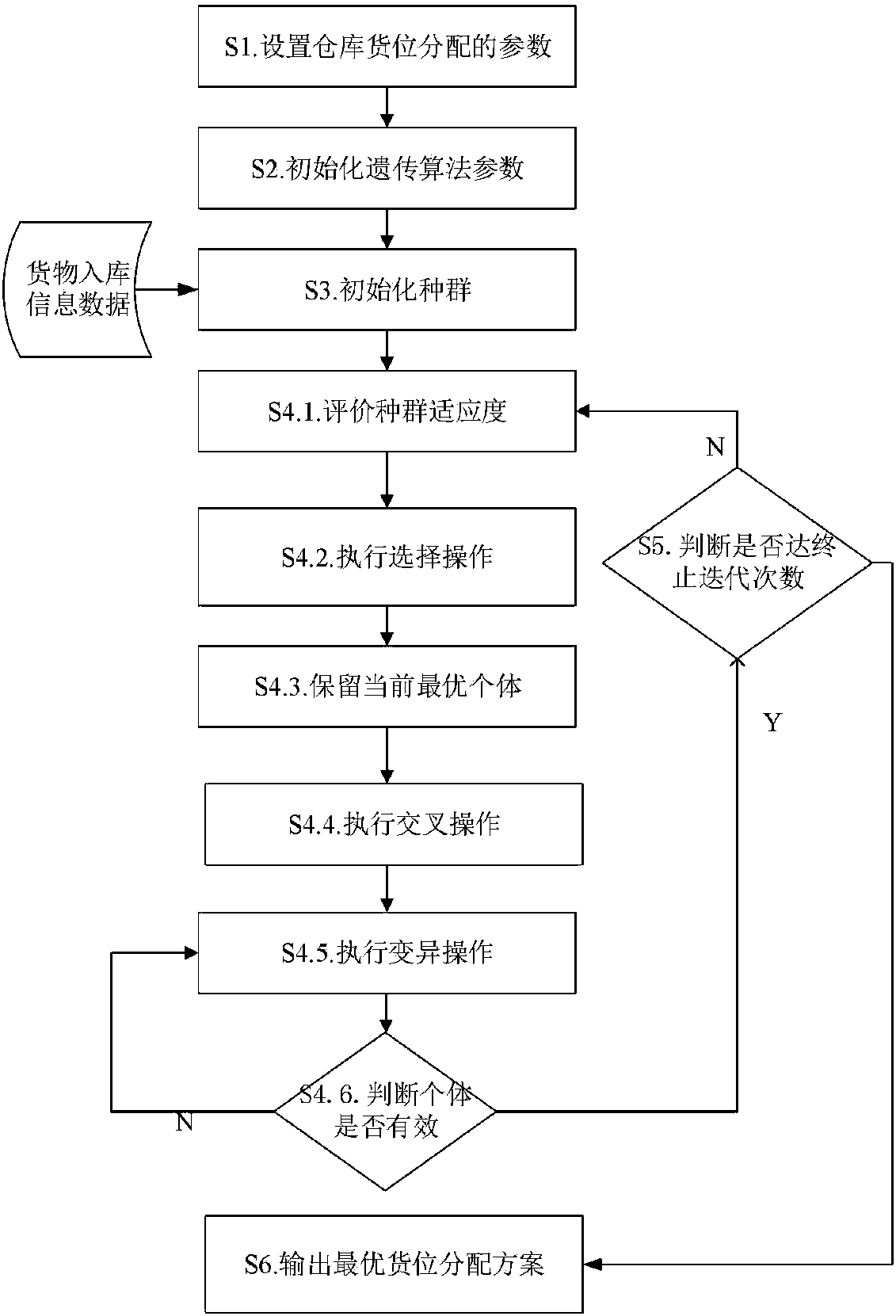

[0085] refer to figure 1 , an optimization method for cargo location allocation applied to a Flying-V non-traditional layout warehouse. The implementation steps are as follows:

[0086] S1. Set the relevant parameters in the Flying-V warehouse location allocation method;

[0087] S2. Initialize the parameters of the genetic algorithm for slot allocation;

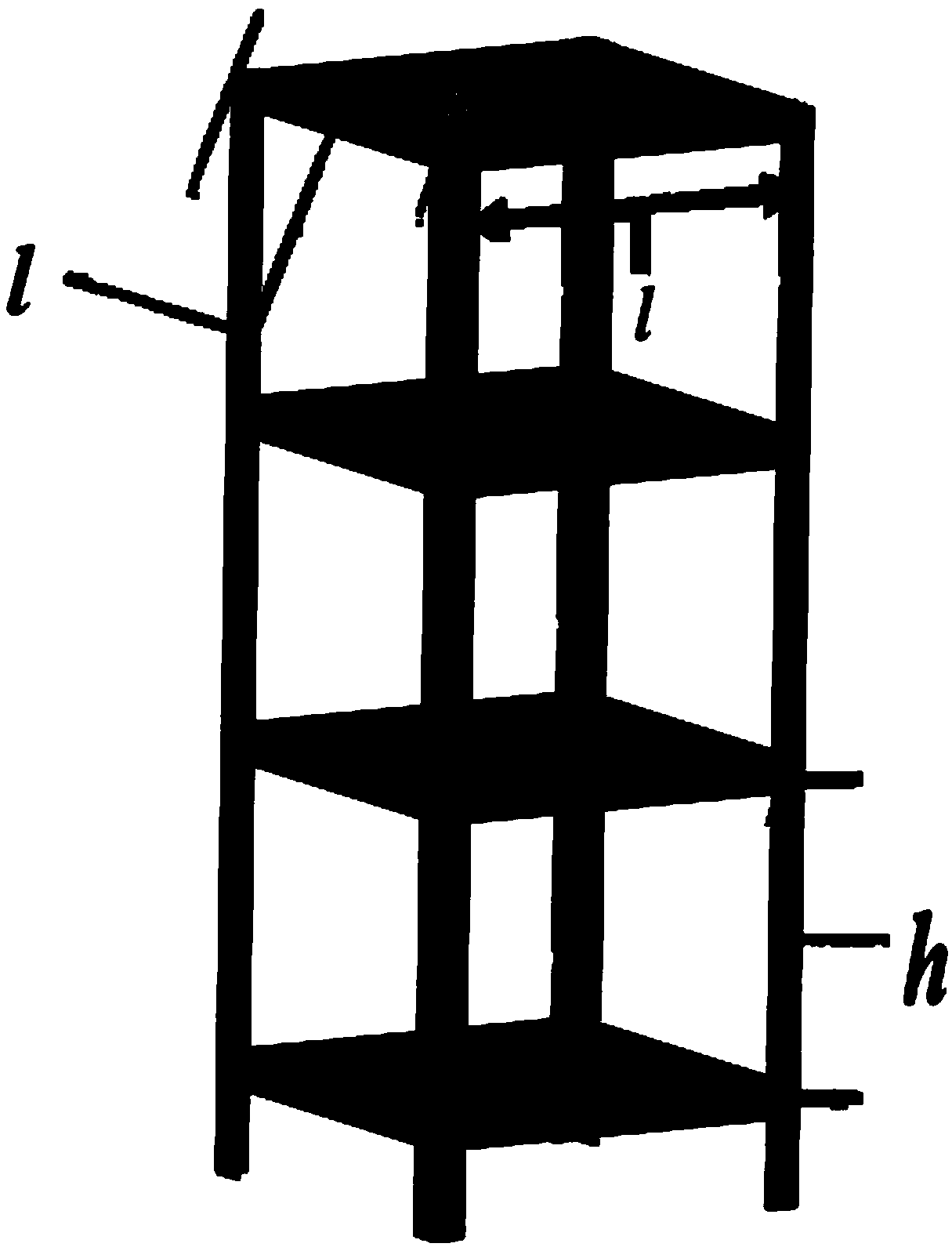

[0088] S3. Initialize the population according to the information list of goods to be put into storage. The location information of each cargo location is composed of 4 dimension parameters, which are the cargo area number, the row number of the cargo location, the column number of the cargo location, and the number of layers of the cargo location;

[0089] S4. Use the adaptive genetic algorithm to perform individual optimal selection on the population, including:

[0090] S4.1. Evaluate the objective function value a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com