A device and method for vacuum thermal correction profile of titanium alloy welding components

A technology for welding components and titanium alloys, which is used in forming tools, metal processing equipment, manufacturing tools, etc., and can solve problems such as the inability to guarantee the profile requirements of the profile and the deformation of the part profile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with embodiment.

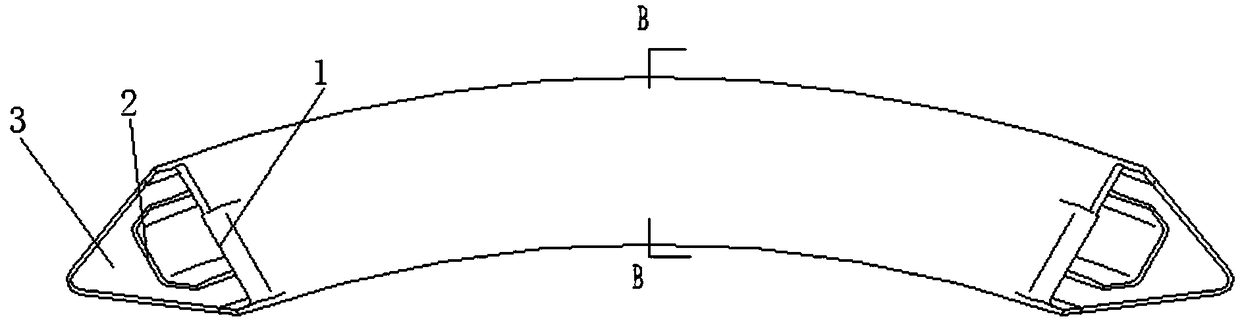

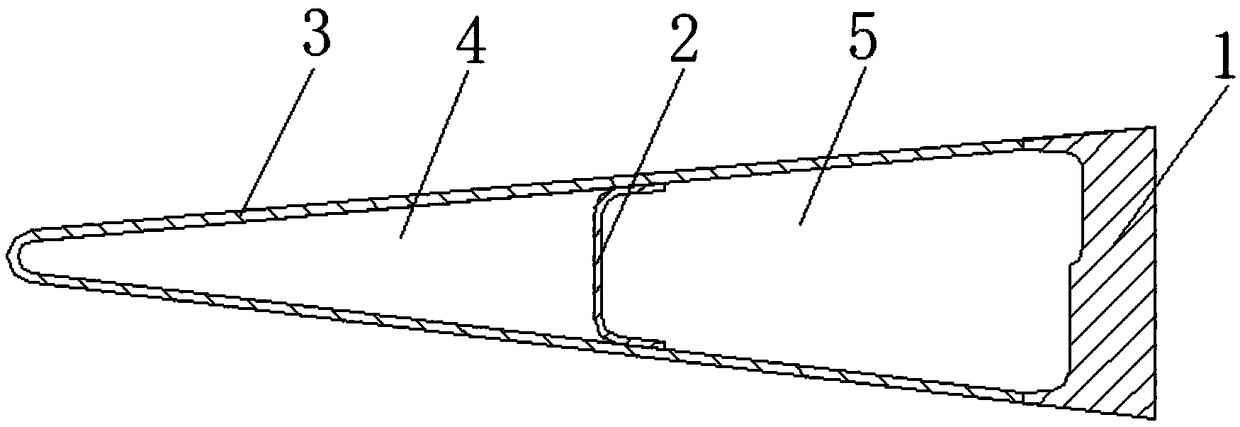

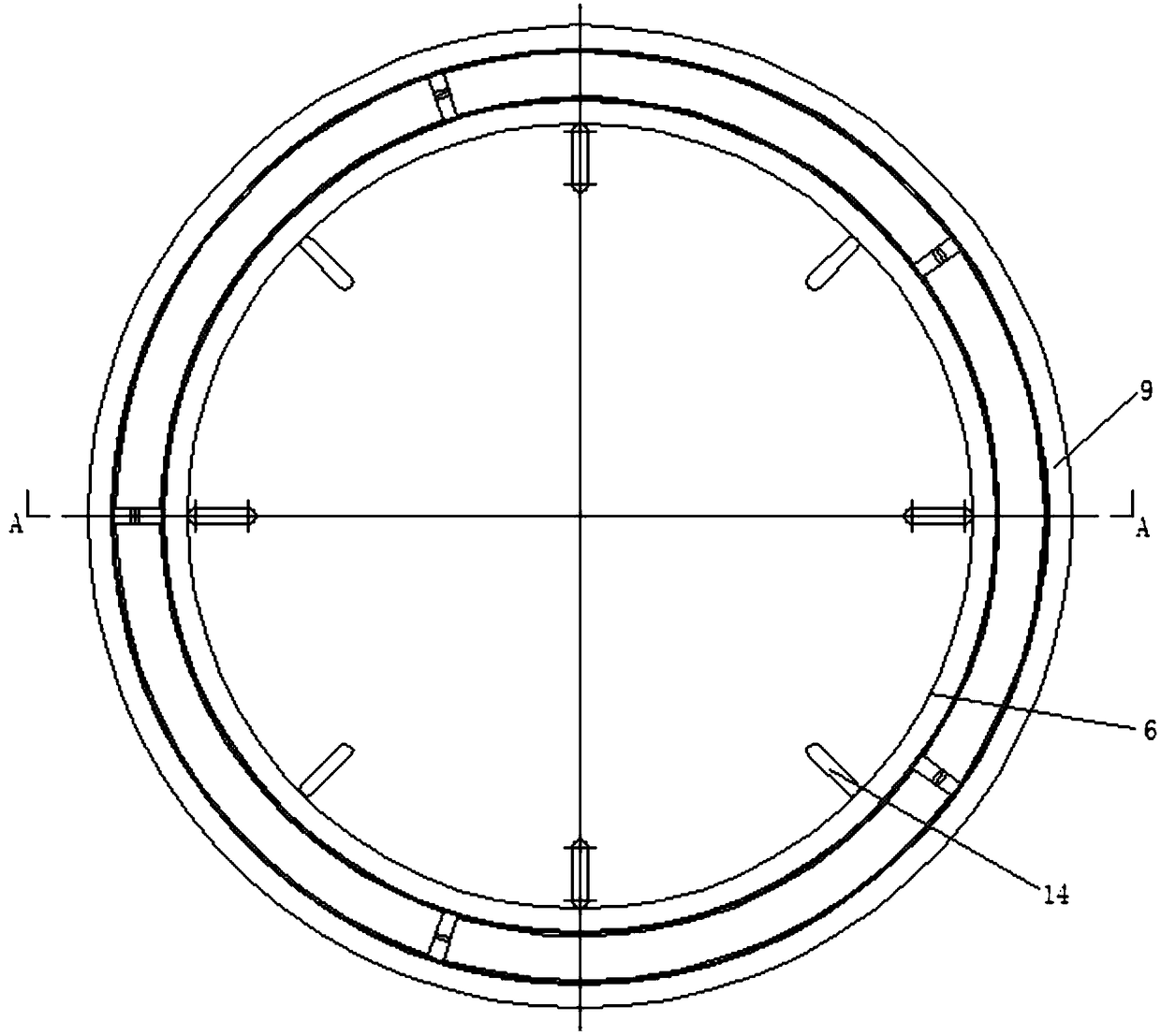

[0028] The invention provides a device for vacuum thermal correction profile of titanium alloy welded components, which is used to correct profile deformation of titanium alloy welded components, according to Figure 1 ~ Figure 2 As shown, the titanium alloy welding member is composed of a single piece 1, a single piece 2 and a single piece 3, the single piece 3 is a V-shaped piece, the single piece 2 is a U-shaped piece, and the single piece 2 is a U-shaped piece. The two U-shaped sides of the single piece 2 are overlapped on the two V-shaped sides of the single piece 3 3, the single piece 1 is located at the open end of the single piece 3, and it is overlapped on the said single piece 3. The two V-shaped edge ends of the single piece three 3 form a cylindrical structure with a triangular cross-sectional shape with the single piece three 3, and a first void is formed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com