A method for regulating humidity and electric pressure cooker

An electric pressure cooker and humidity technology, which is applied to pressure cookers, heating methods, cooking utensils, etc., can solve the problems of high energy consumption, low safety factor, and non-dry heating of humidifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

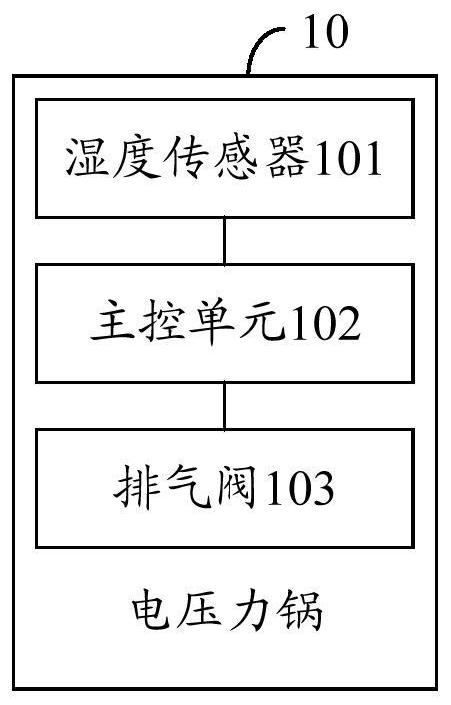

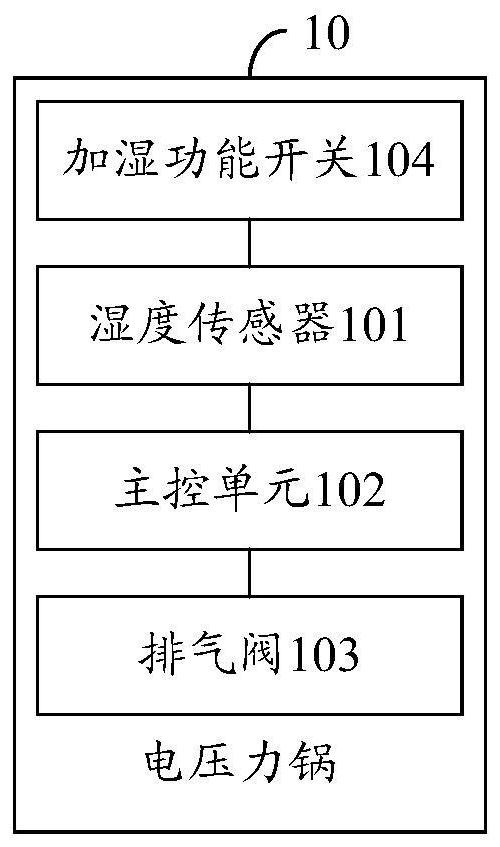

[0050] see figure 1 , which shows an electric pressure cooker 10 for regulating humidity provided by an embodiment of the present invention. The electric pressure cooker 10 may include: a humidity sensor 101, a main control unit 102 and an exhaust valve 103; the humidity sensor 101 and the exhaust valve 103 are connected to the main Control unit 102 is connected; Wherein,

[0051] The humidity sensor 101 is used to detect the current indoor humidity and transmit the current humidity to the main control unit 102;

[0052] The main control unit 102 is configured to generate a control instruction according to the current humidity and the working state of the electric pressure cooker, and transmit the control instruction to the exhaust valve 103;

[0053] The exhaust valve 103 is used to open or close according to the control command.

[0054] It should be noted that, by figure 1 In the method shown, the main control unit 102 controls the opening or closing of the exhaust valve 1...

Embodiment 2

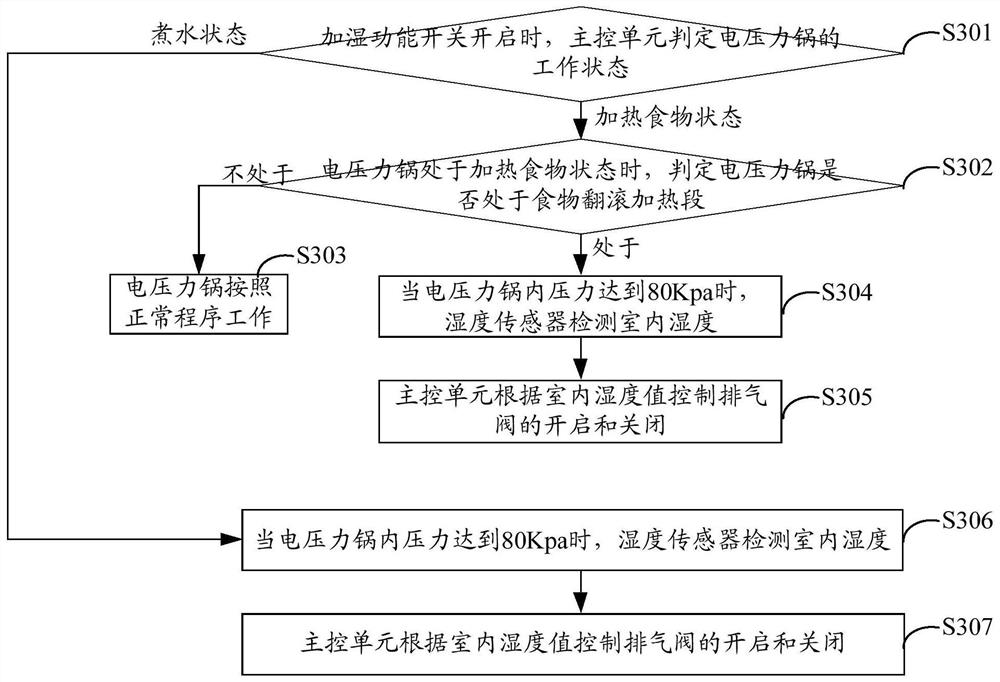

[0072] Based on the same technical idea of the foregoing embodiments, see image 3 , which shows a specific flow of a method for adjusting humidity provided by an embodiment of the present invention, which can be applied to figure 1 The shown electric pressure cooker can specifically be an electric pressure cooker, and the process can include:

[0073] S301: When the humidification function switch is turned on, the main control unit determines the working state of the electric pressure cooker; when it is in the state of heating food, go to S302; when it is in the state of boiling water, go to S306;

[0074] It should be noted that the humidification function switch may specifically be a physical switch or a touch switch, and the humidity adjustment control of the subsequent electric pressure cooker is turned on or off by receiving the user's operation.

[0075] S302: When the electric pressure cooker is in the state of heating food, determine whether the electric pressure c...

Embodiment 3

[0089] Based on the same technical idea of the foregoing embodiments, see Figure 7 , which shows a method for adjusting humidity provided by an embodiment of the present invention, which is applied to figure 1 An electric pressure cooker as shown; the method may include:

[0090] S701: the humidity sensor detects the current indoor humidity;

[0091] S702: the main control unit generates a control instruction according to the current humidity and the working state of the electric pressure cooker;

[0092] S703: The exhaust valve is opened or closed according to the control instruction.

[0093] Exemplarily, an electromagnetic coil is provided in the exhaust valve, and the opening and closing of the exhaust valve is controlled correspondingly by energizing and de-energizing the electromagnetic coil. Correspondingly, the control instruction can be specifically used to control the Energizing or de-energizing the solenoid coil.

[0094] Exemplarily, since the embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com