Multi-stage continuous heating device, heating method and household appliances using the device

A heating device and heating tube technology, which is applied in the field of household appliances and multi-stage continuous heating devices, can solve the problems of limited heating space of the heating reed, low space utilization of the heating reed, and large size of the heating reed, so as to improve the availability space, improve the efficiency of steam output, and avoid the effects of dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

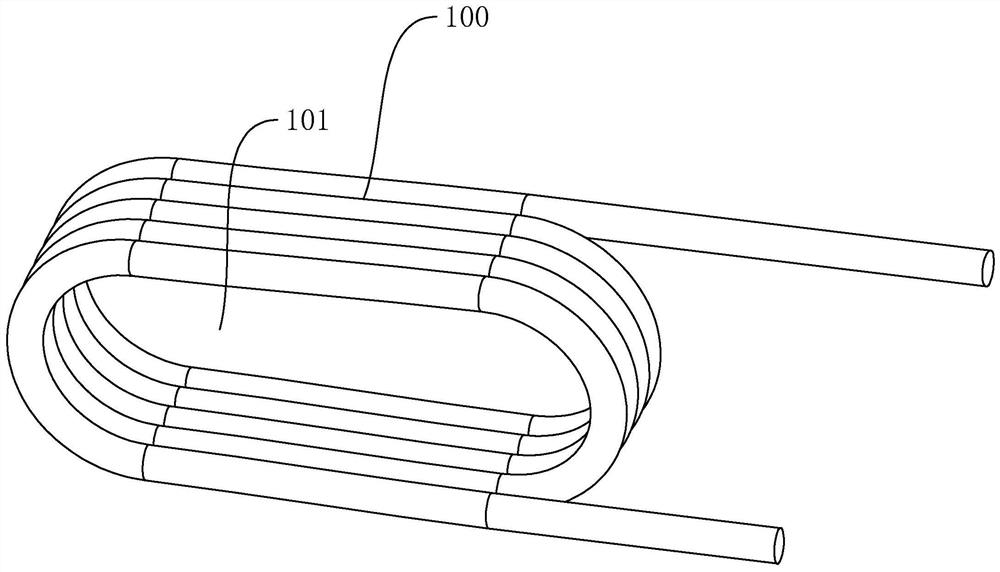

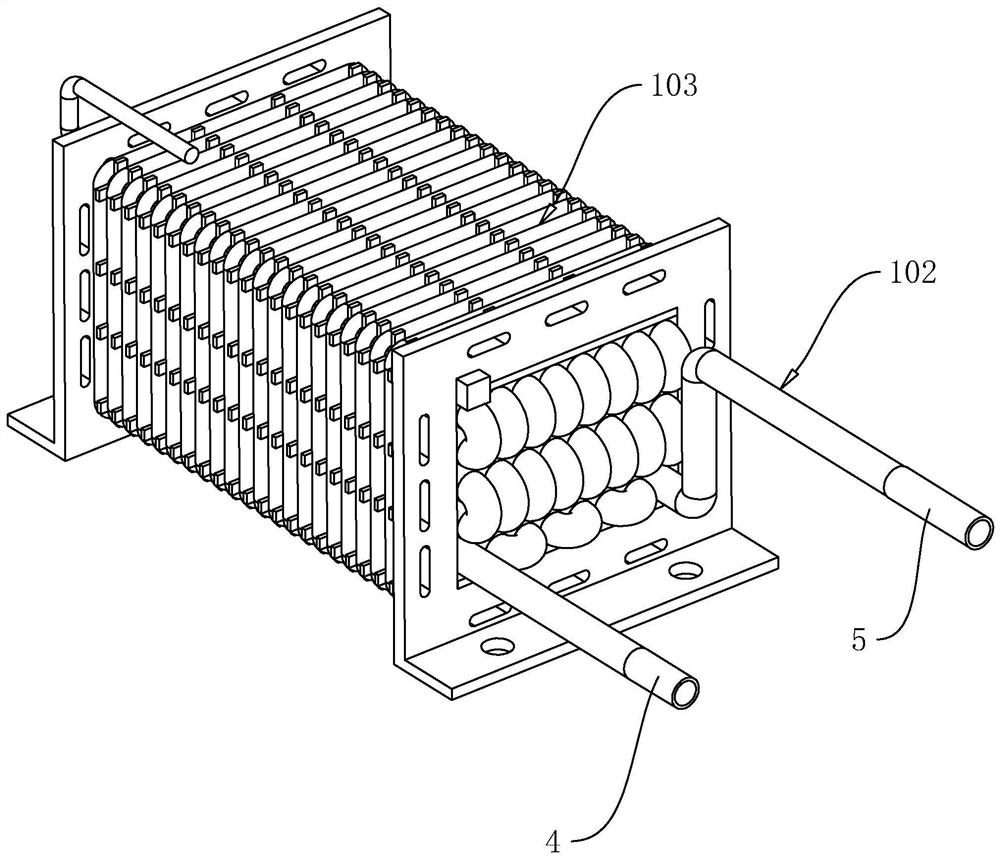

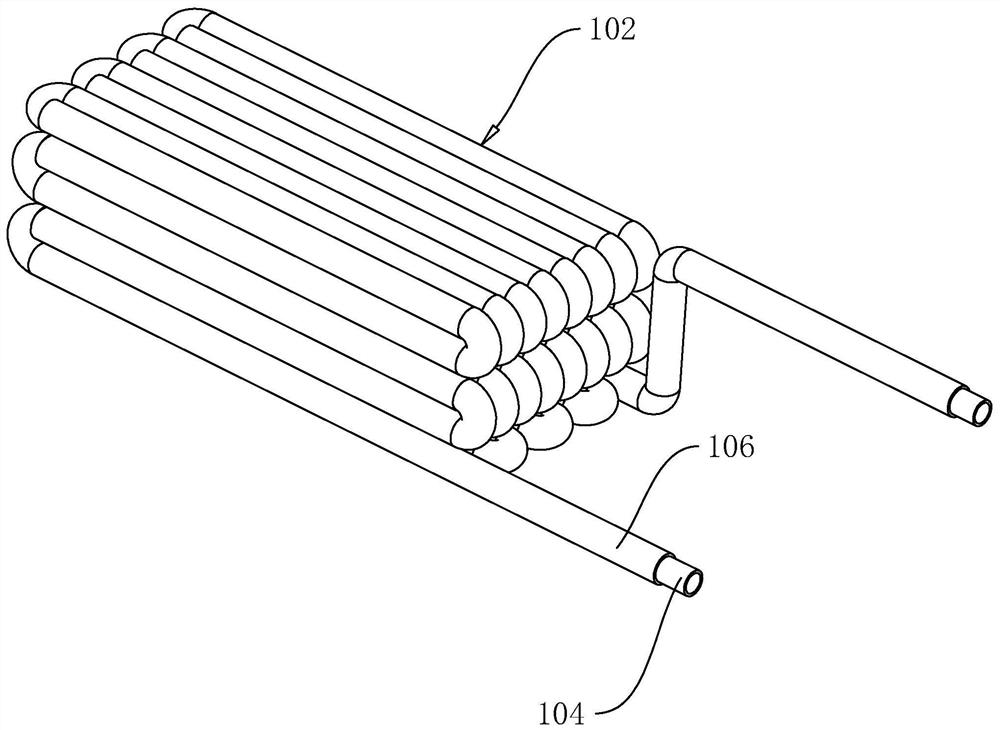

[0051] refer to figure 2 , 3 , the multi-stage continuous heating device includes a water inlet pipe 4, a heating assembly 102, and a steam outlet pipe 5. In this embodiment, the heating assembly 102 includes a circular single-chamber heating pipe and an electromagnetic coil 103, and the single-chamber heating pipe is provided with One, in other embodiments, multiple single-chamber heating tubes can be provided according to actual needs. The single-chamber heating tube includes a magnetically conductive iron tube 106 and a stainless steel tube 104. The outer wall of the stainless steel tube 104 is closely attached to the inner wall of the iron tube 106. In fact, the iron tube 106 and the stainless steel tube 104 form a composite tube in a nesting relationship. In addition, the inner wall of the stainless steel pipe 104 constitutes a heating chamber of the heating component 102, and the heating chamber provides a storage space for the water to be heated.

[0052] refer to ...

Embodiment 2

[0063] refer to Figure 6 , the heating assembly 102 includes a single-chamber heating tube with a zigzag cross section. In this embodiment, except that the section of the heating assembly 102 is different, the single-chamber heating tube includes a magnet-conducting tube 106 and a stainless steel tube 104 with a square section, and the rest are the same as in the first embodiment. refer to Figure 7, the single-chamber heating tube with a zigzag cross section can be further adapted to the rectangular accommodation channel 224, and in view of this, the space utilization rate of the accommodation channel 224 can be further improved, thereby facilitating the improvement of heating efficiency and steam output speed. In addition, a round pipe 105 is connected to the cold water inlet end and the steam outlet end of the single-chamber heating pipe, and the round pipe 105 communicates with the single-chamber heating pipe. The mutual cooperation of the pipes 104 can further facilita...

Embodiment 3

[0065] refer to Figure 8 , 9 , the heating assembly 102 includes a multi-chamber heating tube with a nine-square grid cross section. In this embodiment, except for the cross-sectional shape, the others are the same as in Embodiment 1. At the same time, the multi-chamber heating tube is provided with a, refer to Figure 8 , one chamber of the multi-chamber heating pipe corresponds to one heating chamber, that is, in this embodiment, there are 9 heating chambers, by increasing the number of heating chambers, the contact area of the water to be heated can be effectively increased, thereby improving The heating efficiency can indirectly improve the steam output efficiency. In other embodiments, the number of heating chambers can be set as required. In addition, a round pipe 105 is connected to the cold water inlet end and the steam outlet end of the multi-chamber heating pipe, and the round pipe 105 communicates with the multi-chamber heating pipe. The mutual cooperation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com