Electric water heater provided with water inlet guide pipe

An electric water heater and a diversion tube technology, which is applied in the directions of water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of lowering the water level of the water storage tank 1, potential safety hazards of the electric water heater, and dry burning of the electric water heater, etc. To achieve the effect of eliminating potential safety hazards, reducing water backflow, and preventing dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

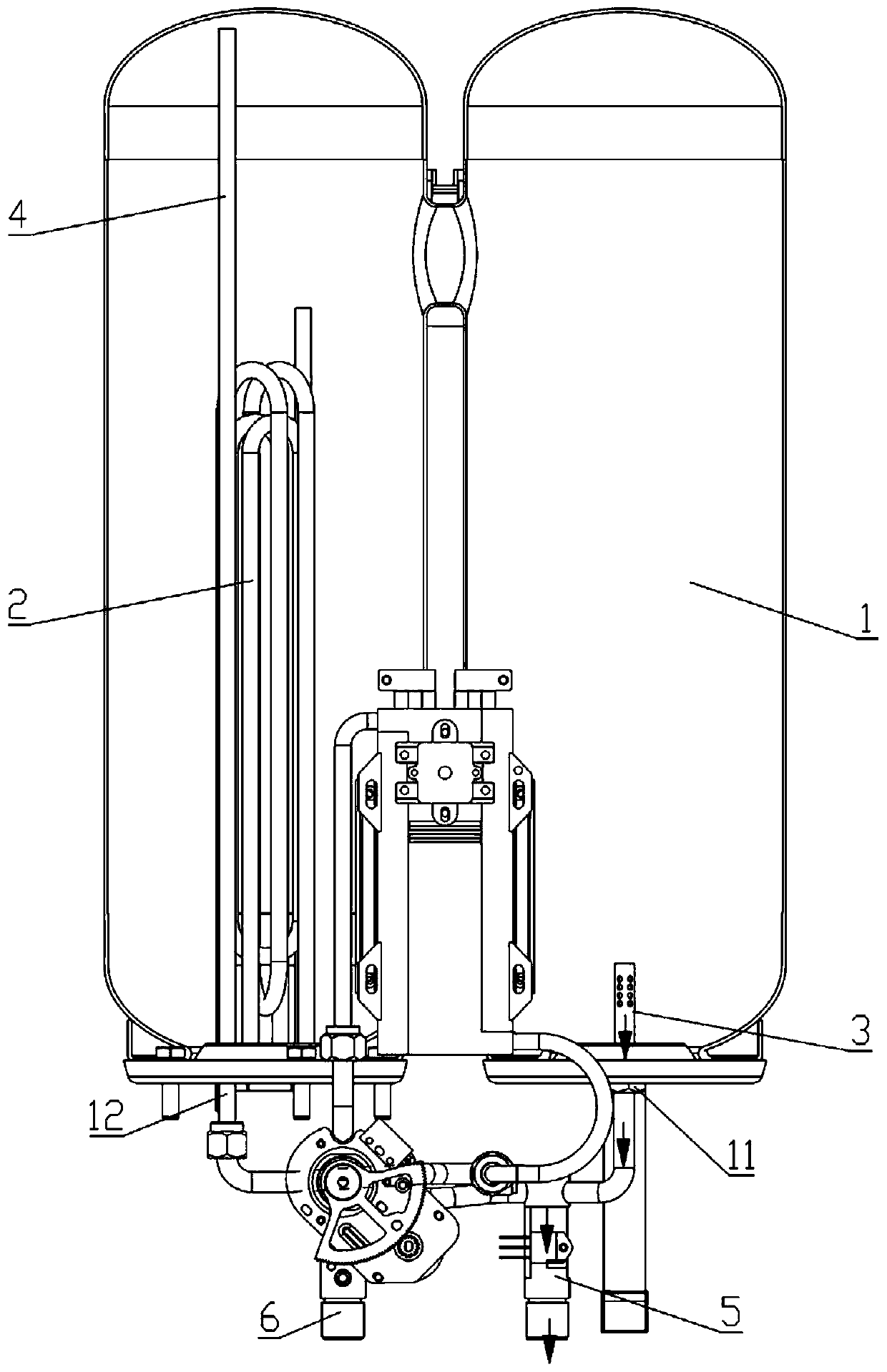

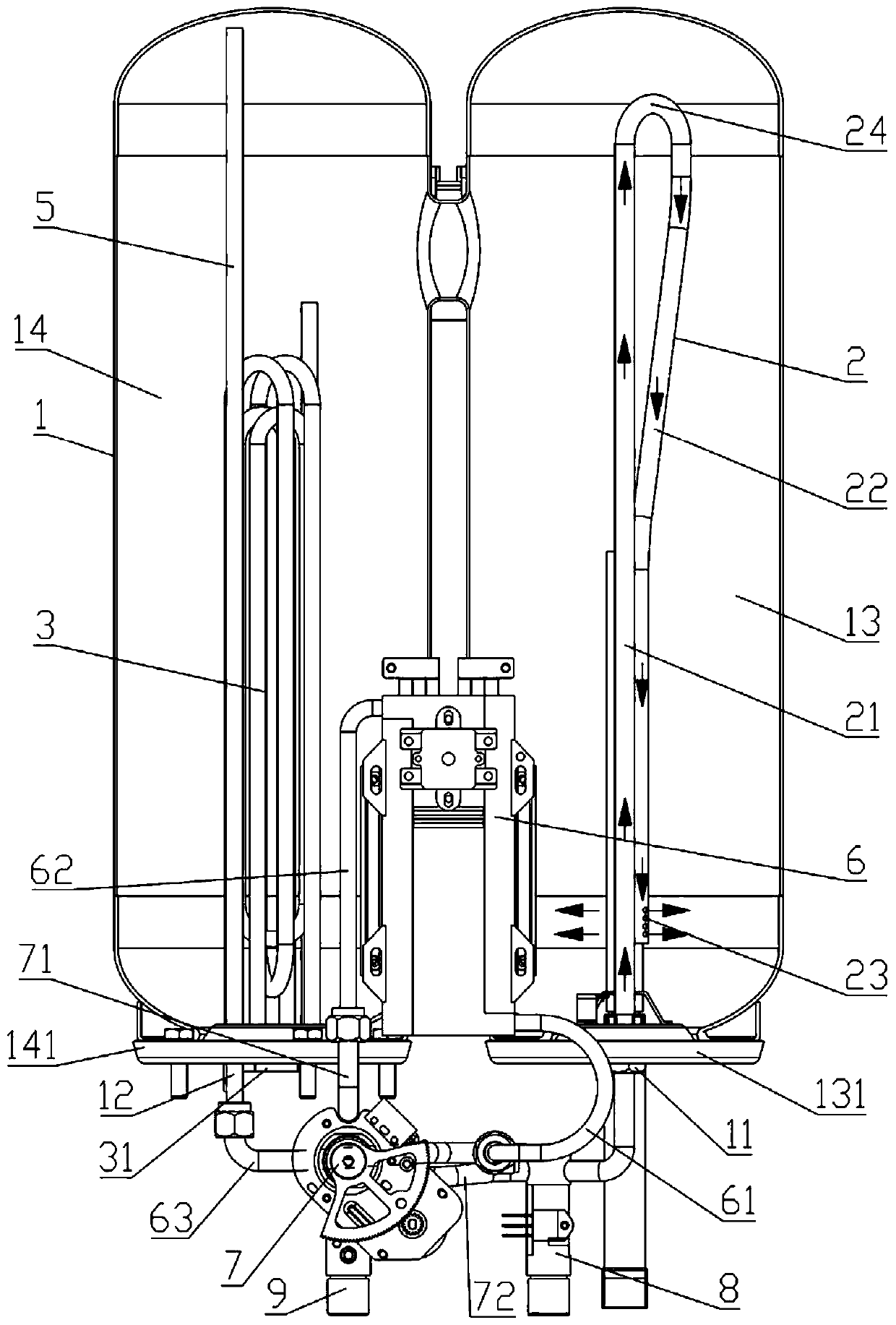

[0023] refer to figure 2 , an electric water heater provided with a water inlet diversion pipe, which includes a water storage liner 1, an inlet water diversion pipe, a preheating electric heating pipe 3, an outlet water diversion pipe 5, a cast aluminum electric heater and a constant temperature outlet valve 7 .

[0024] The water storage inner tank 1 has a first inner tank part 13 and a second inner tank part 14 arranged symmetrically from left to right and connected to each other. The bottom ends of the first inner tank part 13 and the second inner tank part 14 are respectively provided with second A mounting base 131 and a second mounting base 141 . The first mounting seat 131 has an inner tank water inlet and an inner tank water inlet joint 11 . The second mounting base 141 has an inner tank water outlet and is provided with an inner tank water outlet joint 12 .

[0025] The preheating electric heating tube 3 is installed in the second liner part 14 of the water stora...

Embodiment 2

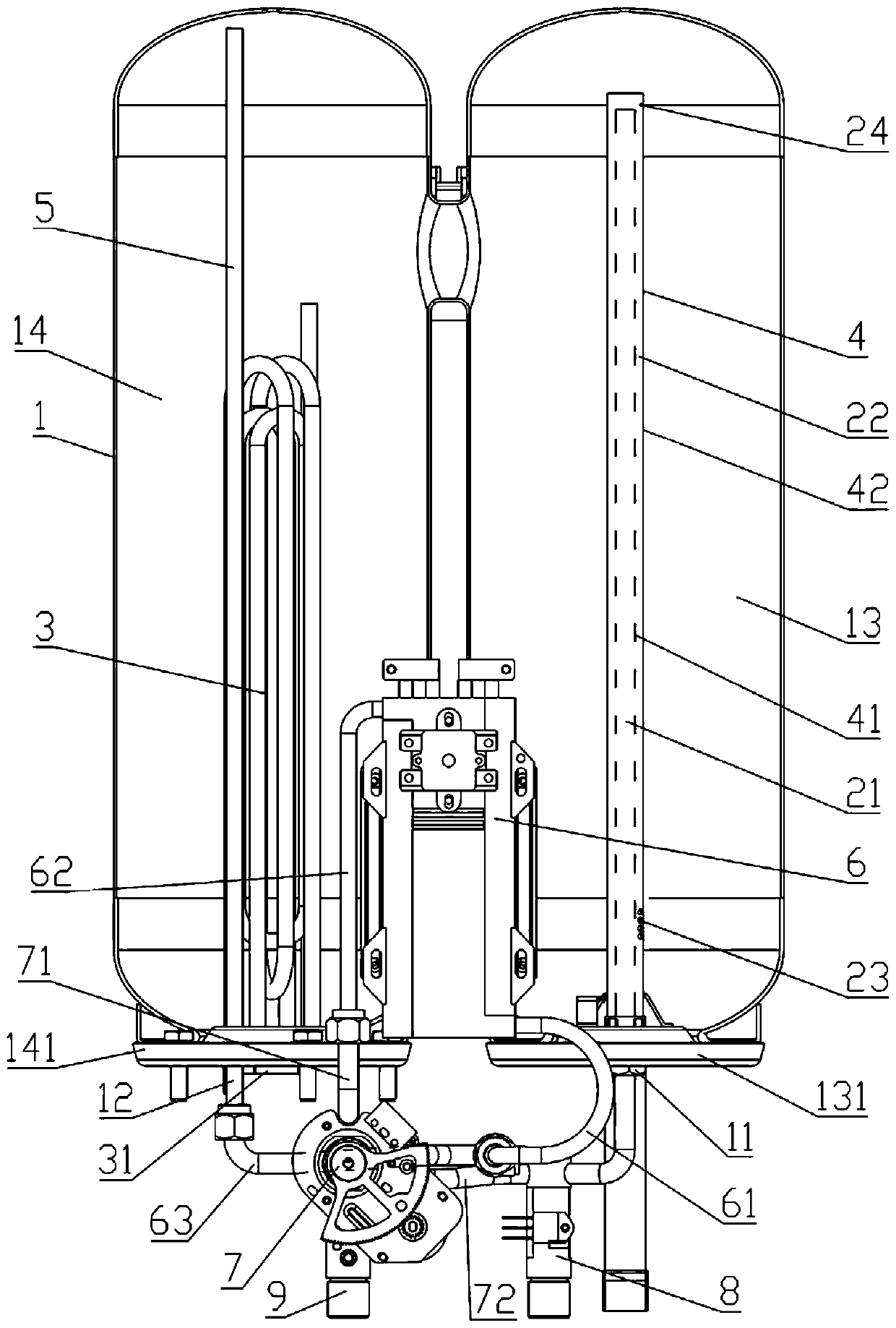

[0034] refer to image 3 and Figure 4 , The electric water heater provided with the water inlet guide pipe of this embodiment differs from Embodiment 1 in that: the water inlet guide pipe in this embodiment is a double-layer guide pipe 4 .

[0035] The double-layer guide tube 4 has an inner tube part 41 and an outer tube part 42 . The outer pipe part 42 is a tubular structure with an end plate 421 at one end and a closed end at the other end. The middle part of the end plate 421 has a socket hole, and the side wall near the end plate 421 of the outer pipe part 42 has a plurality of water supply ports 23 with a hole-shaped structure. 1. There is an exhaust hole 24 on the side wall near the closed end. The inner tube part 41 is a tubular structure with a connection port 411 at one end and a communication port 412 at the other end. The inner tube part 41 is coaxially inserted into the outer tube part 42 through the sleeve hole of the outer tube part 42, and its connection port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com