Leg fixing device for milking cows

A fixing device and leg technology, which is applied in the field of livestock breeding tools, can solve the problems of thread grinding, complicated operation, inconvenient use, etc., and achieve the effect of preventing thread grinding, simple operation, and preventing kicking injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

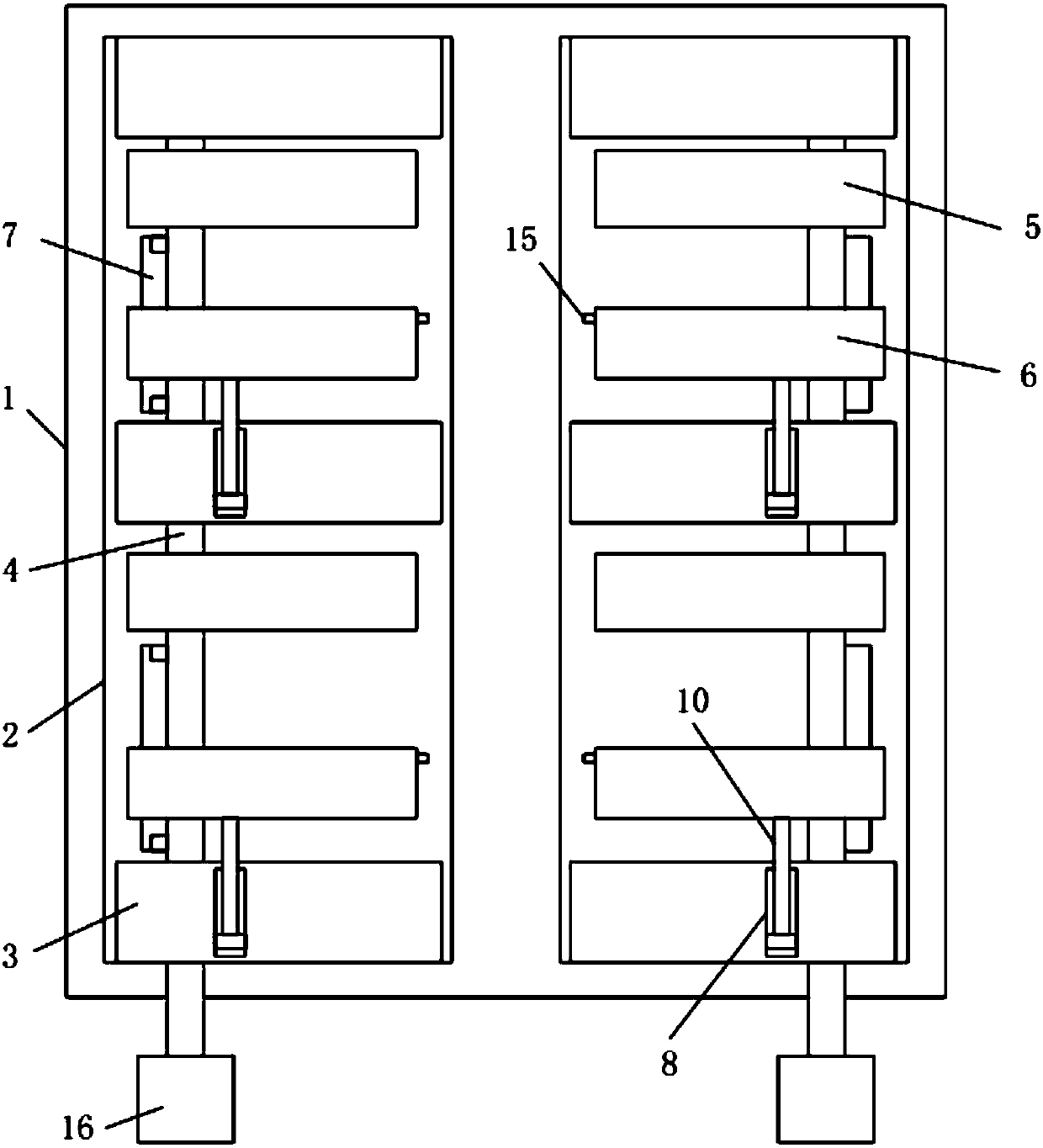

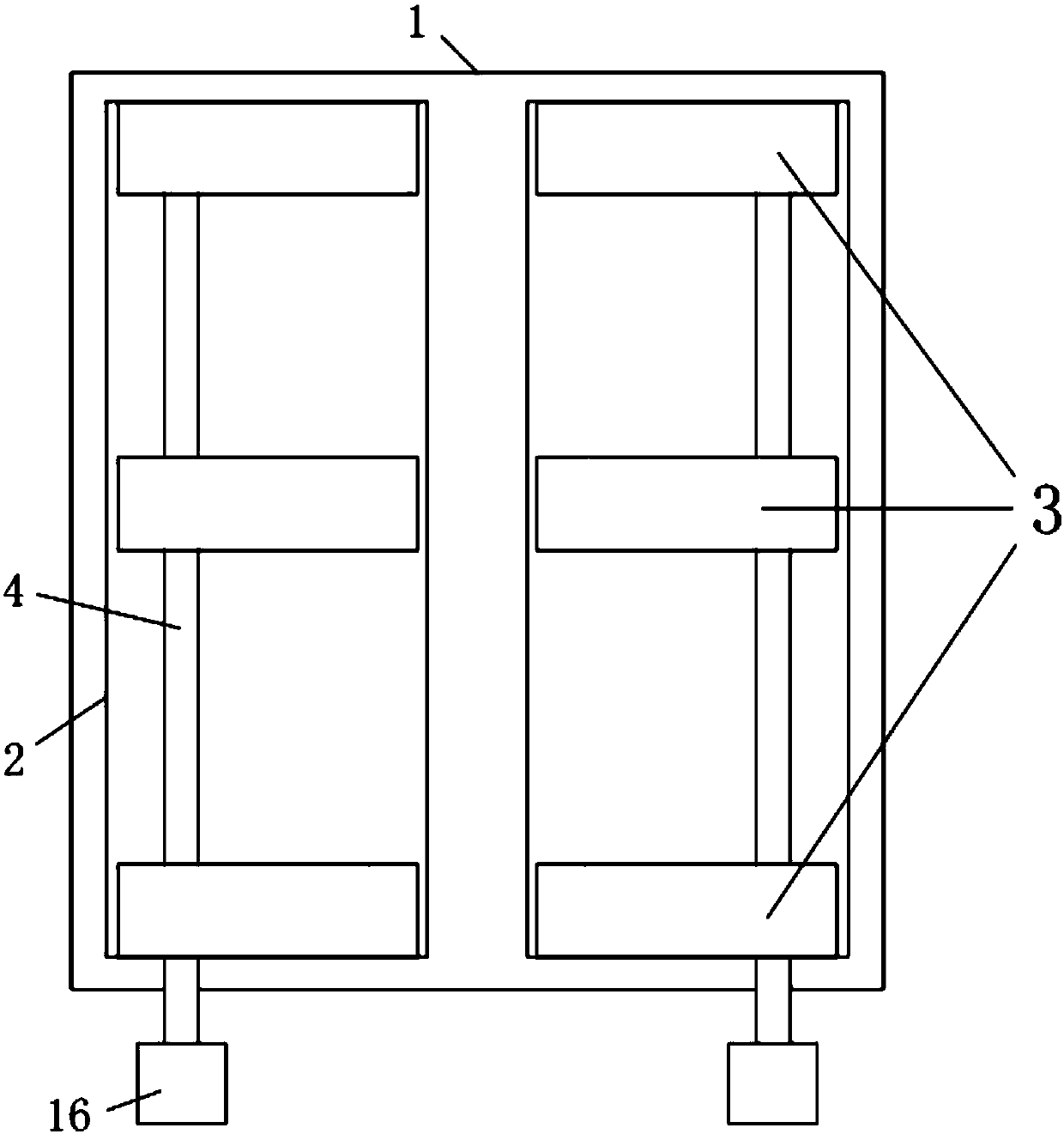

[0031] A leg fixing device for milking cows, including a main board 1 and a fixing mechanism, the main board 1 is used to place under the body of the cow, and the fixing mechanism is used to clamp the cow leg 100 for fixing.

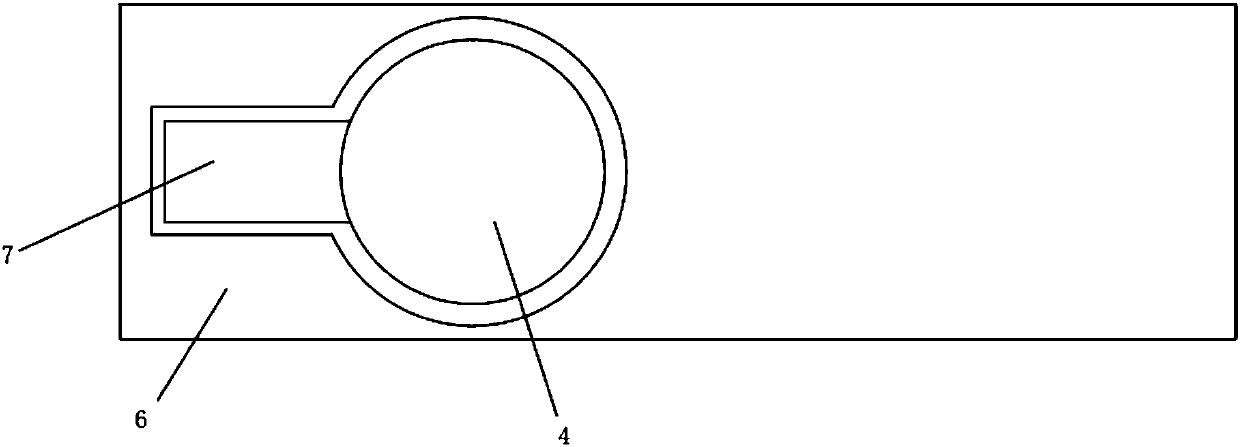

[0032] Two substrates 2 are symmetrically fixed on the mainboard 1. The two substrates 2 are not in contact with each other and are directly welded on the mainboard 1. Three mounting plates 3 are arranged at intervals on the substrate 2, and three mounting plates 3 are fixed on each substrate 2. A rotating shaft 4 is movably inserted in the mounting plate 3. One end of the rotating shaft 4 passes through the two mounting plates 3 in turn, and finally rotates and is inserted on the last mounting plate 3. A handle 16 is fixed at one end of the rotating shaft 4, which is convenient for milking Personnel rotate the rotating shaft 4 so that the rotating shaft 4 can freely complete the rotation. The fixing mechanism is arranged between every two mounting plates...

Embodiment 2

[0035] A leg fixing device for milking cows, including a main board 1 and a fixing mechanism, the main board 1 is used to place under the body of the cow, and the fixing mechanism is used to clamp the cow leg 100 for fixing.

[0036] Two substrates 2 are symmetrically fixed on the mainboard 1. The two substrates 2 are not in contact with each other and are directly welded on the mainboard 1. Three mounting plates 3 are arranged at intervals on the substrate 2, and three mounting plates 3 are fixed on each substrate 2. A rotating shaft 4 is movably inserted in the mounting plate 3, and one end of the rotating shaft 4 passes through the two mounting plates 3 in turn, and finally rotates and is inserted on the last mounting plate 3, so that the rotating shaft 4 can complete the rotation freely, and the fixing mechanism is arranged on Between every two mounting plates 3 , two sets of fixing mechanisms are provided on each base plate 2 , corresponding to four corbels 100 .

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com