Mechanical vibration test teaching device

A technology of mechanical vibration and compound vibration, applied in the direction of instruments, teaching aids, educational appliances, etc., can solve the problems of insufficiency, lack, and increase of compound vibration manufacturing of swing simple-coordinated vibration sources, and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

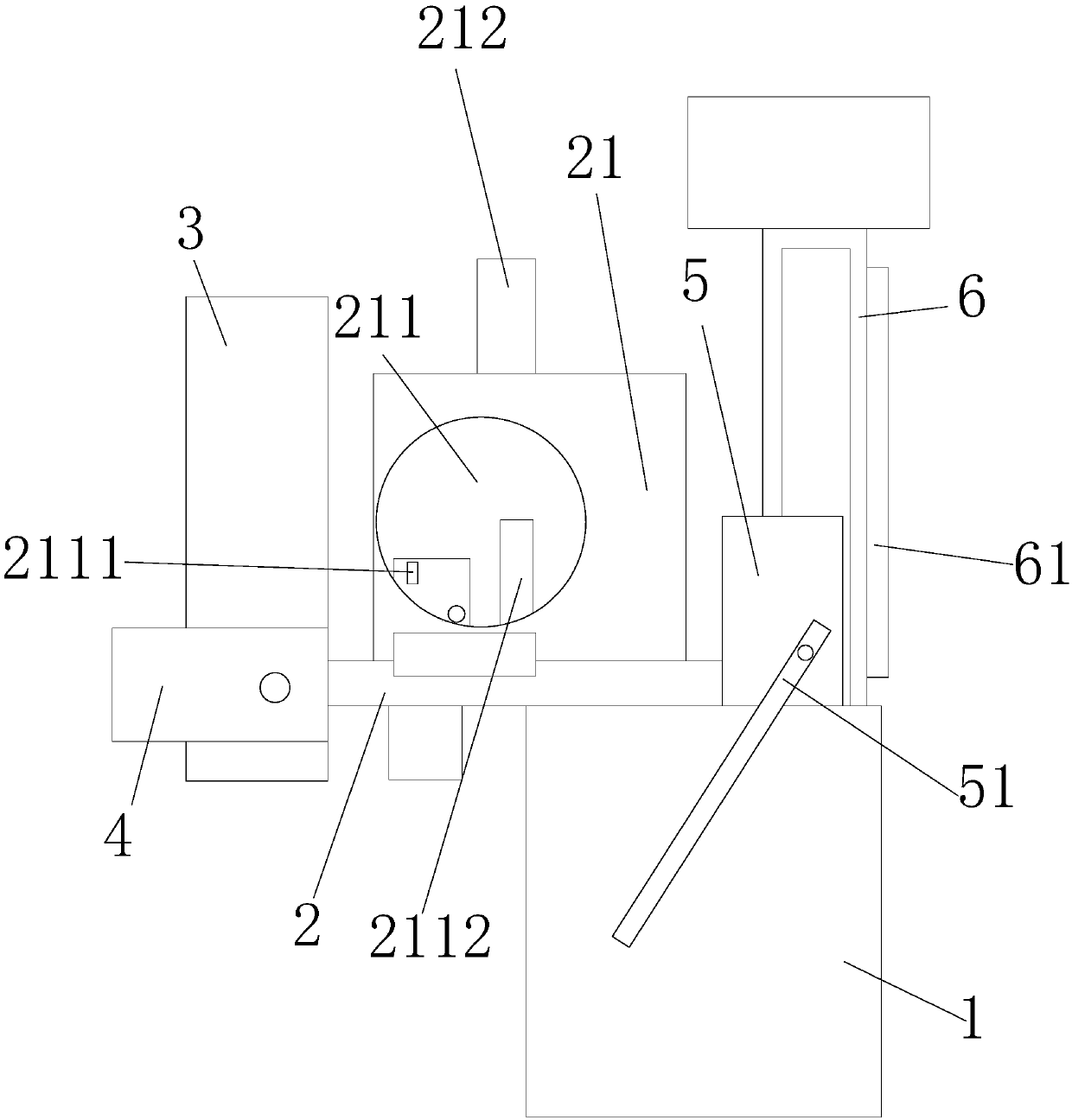

[0011] like figure 1 Shown, a kind of mechanical vibration test teaching device mainly comprises vibration chamber 1, and the upper end of described vibration chamber 1 is equipped with spring pipeline 2, and the upper side of described spring pipeline 2 is equipped with vertical plate 21, and described vertical plate 21 is equipped with a rotating disk 211 and an intubation tube 212, the rotating disk 211 is equipped with an operating table 2111 and a counterweight bias block 2112, and the spring pipe 2 is equipped with a lateral composite vibrator 3 and a hinged guide sleeve 4 , the side composite vibrator 3 and the hinged guide sleeve 4 are welded together, the spring pipe 2, the side composite vibrator 3 and the hinge guide sleeve 4 help to install the spring, the side composite vibration source to manufacture instrument accessories and according to the vibration situation to adjust the position of the auxiliary guide connecting parts.

[0012] The right end of described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com