High speed loading device for gantry polishing machine

A polishing machine, gantry-type technology, applied in grinding/polishing safety devices, surface polishing machine tools, grinding drive devices, etc. Effects of stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

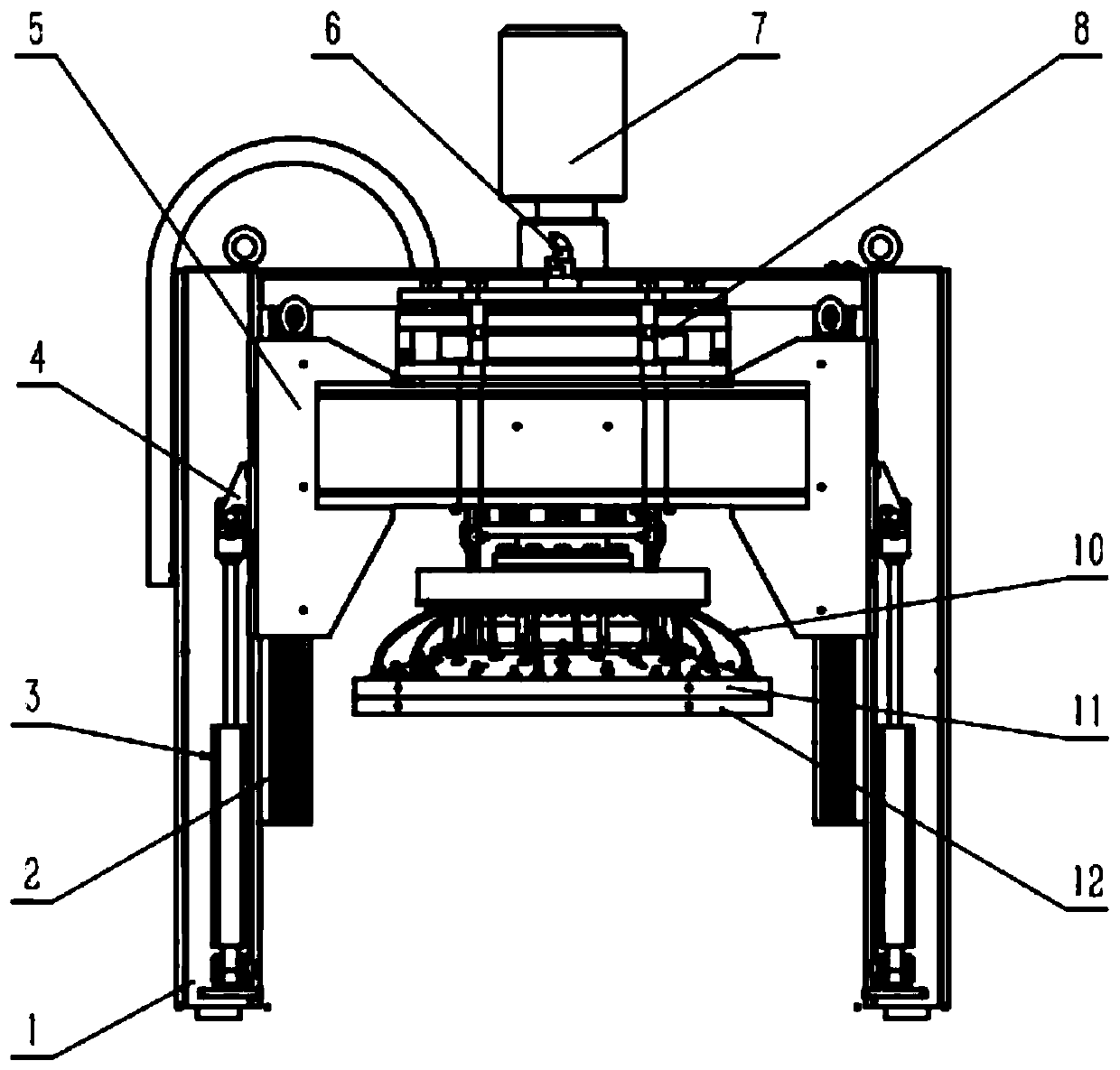

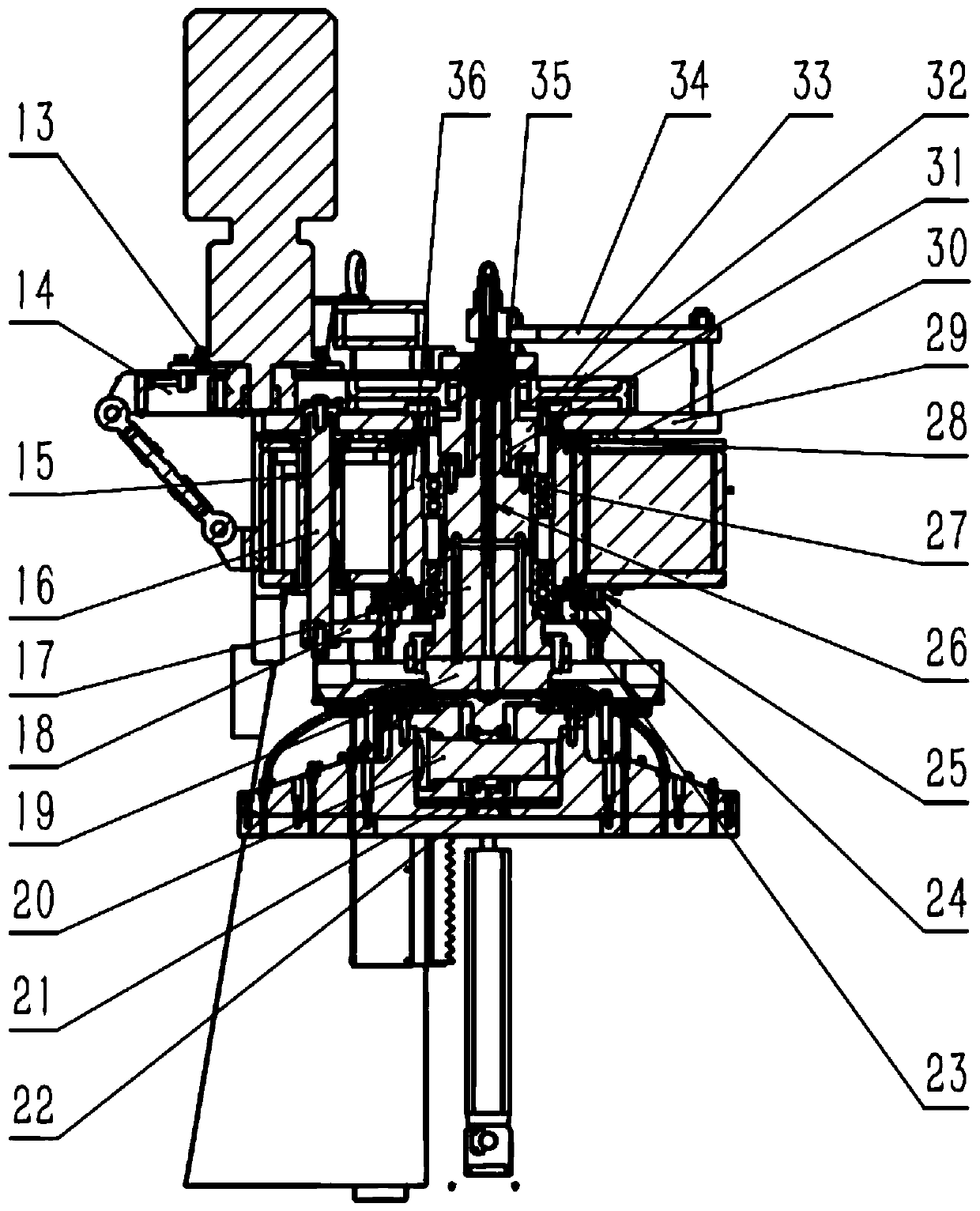

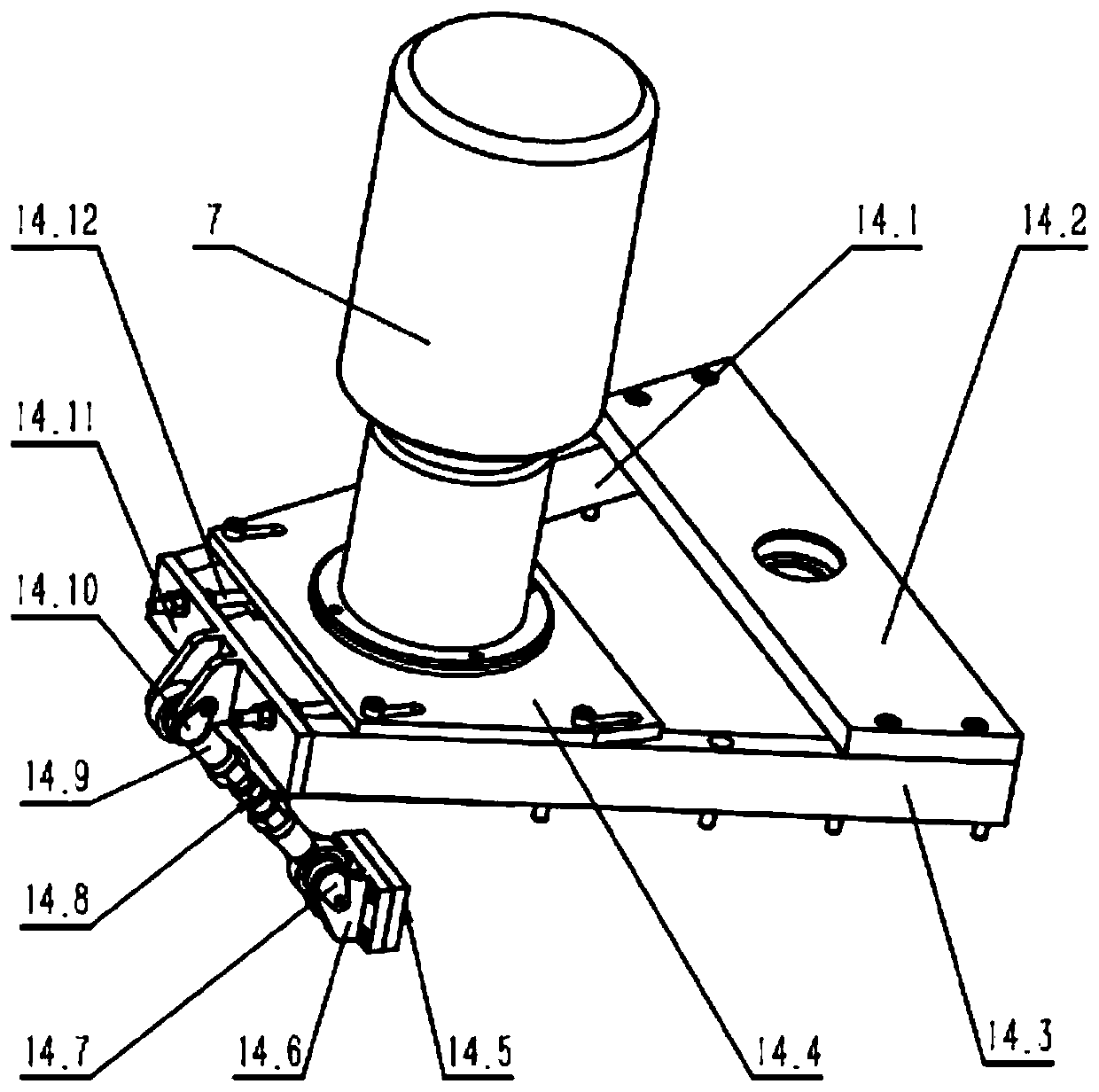

[0020] refer to figure 1 , figure 2 and image 3 , this embodiment includes gantry 1, linear slide rail 2, oil cylinder 3, hinge seat I4, sliding seat 5, rotary joint 6, motor 7, timing belt 8, hose 10, upper plate gland 11, upper polishing plate 12 , small synchronous pulley 13, motor installation assembly 14, guide sleeve 15, guide rod 16, upper main shaft 17, connecting plate 18, lower main shaft 19, pin shaft I20, joint bearing 21, gland 22, lower support plate 23, lower Damping ring 24, rubber damping pad 25, cooling pipe 26, bearing 27, upper damping ring 28, upper support plate 29, damping airbag 30, expansion sleeve 31, large synchronous pulley 32, shaft coupling 33, Counterweight plate 34, self-aligning bearing 35 and bearing seat 36;

[0021] The sliding seat 5 is connected with the gantry 1 through two left and right linear slide rails 2, the upper end of the oil cylinder 3 is connected with the sliding seat 5 through the hinge seat I4, and the sliding seat 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com