Fast start-up method of mems gyroscope based on compound learning of parallel estimation

A fast-start, gyroscope technology, used in instruments, adaptive control, measurement devices, etc., can solve problems such as poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

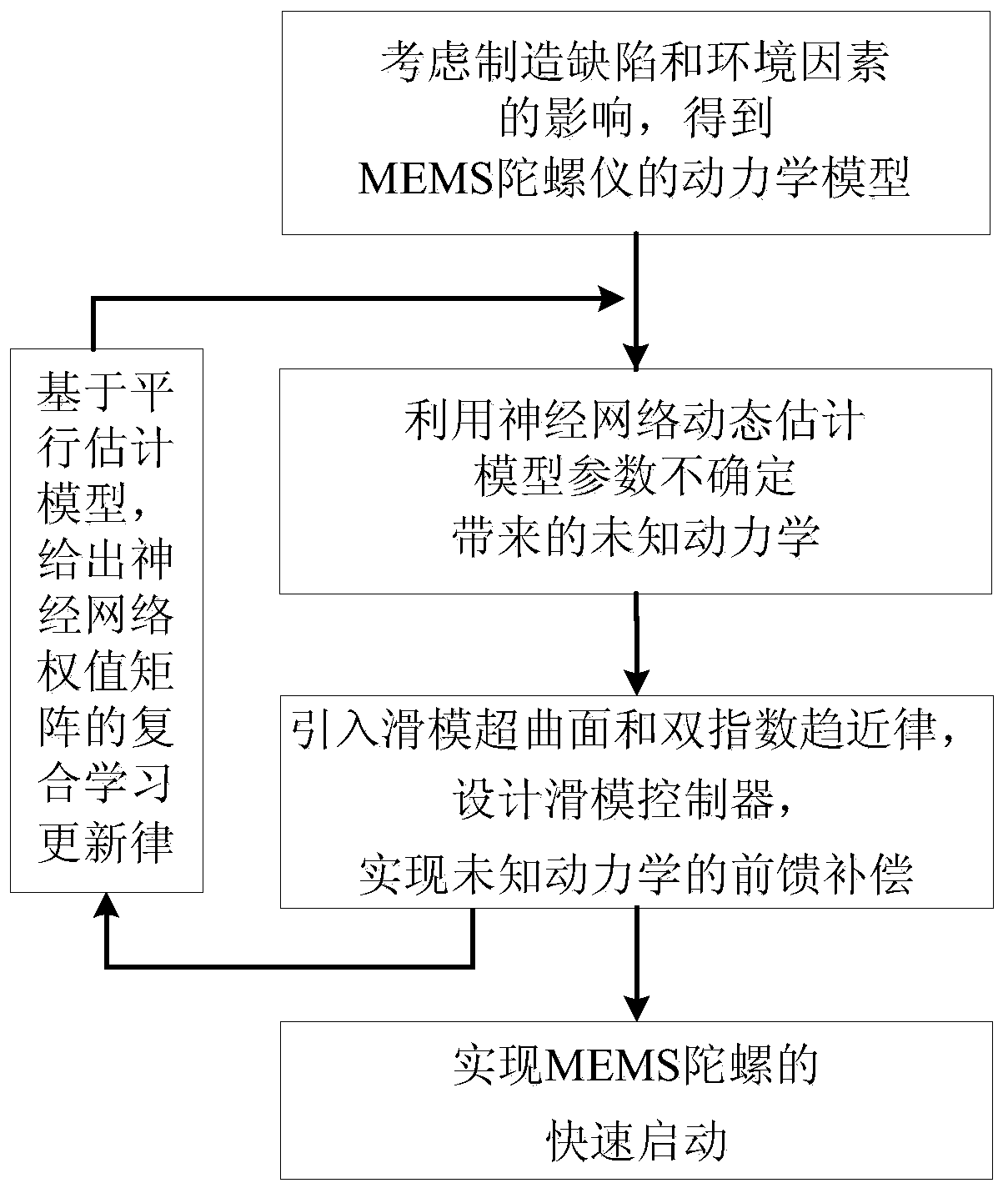

[0070] refer to figure 1 . The present invention is based on the MEMS gyroscope quick-starting method of parallel estimation compound learning The specific steps are as follows:

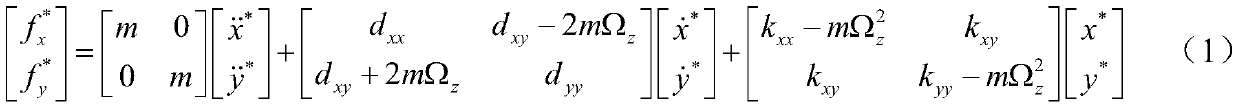

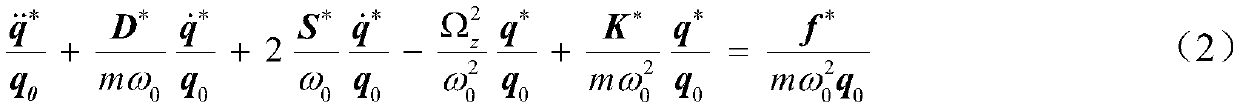

[0071] (a) The dynamic model of the MEMS gyroscope considering the quadrature error is:

[0072]

[0073] Among them, m is the mass of proof mass; Ω z Input the angular velocity for the gyro; is the electrostatic driving force; x * are the acceleration, velocity and displacement of the MEMS gyroscope proof mass along the drive axis; the y * are the acceleration, velocity and displacement of the proof mass along the detection axis; d xx , d yy is the damping coefficient; k xx , k yy is the stiffness coefficient; d xy is the damping coupling coefficient, k xy is the stiffness coupling coefficient.

[0074] In order to improve the accuracy of mechanism analysis, the MEMS gyroscope dynamic model is dimensionless. Take the dimensionless time t * = ω o t, and then divide both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com