Rubber and plastic air pipe

A trachea, rubber and plastic technology, applied in the direction of hose, pipe, pipeline protection, etc., can solve the problems of PU trachea, such as large, broken, hard and brittle pipe body, so as to achieve not easy to wear, long service life, good self-strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

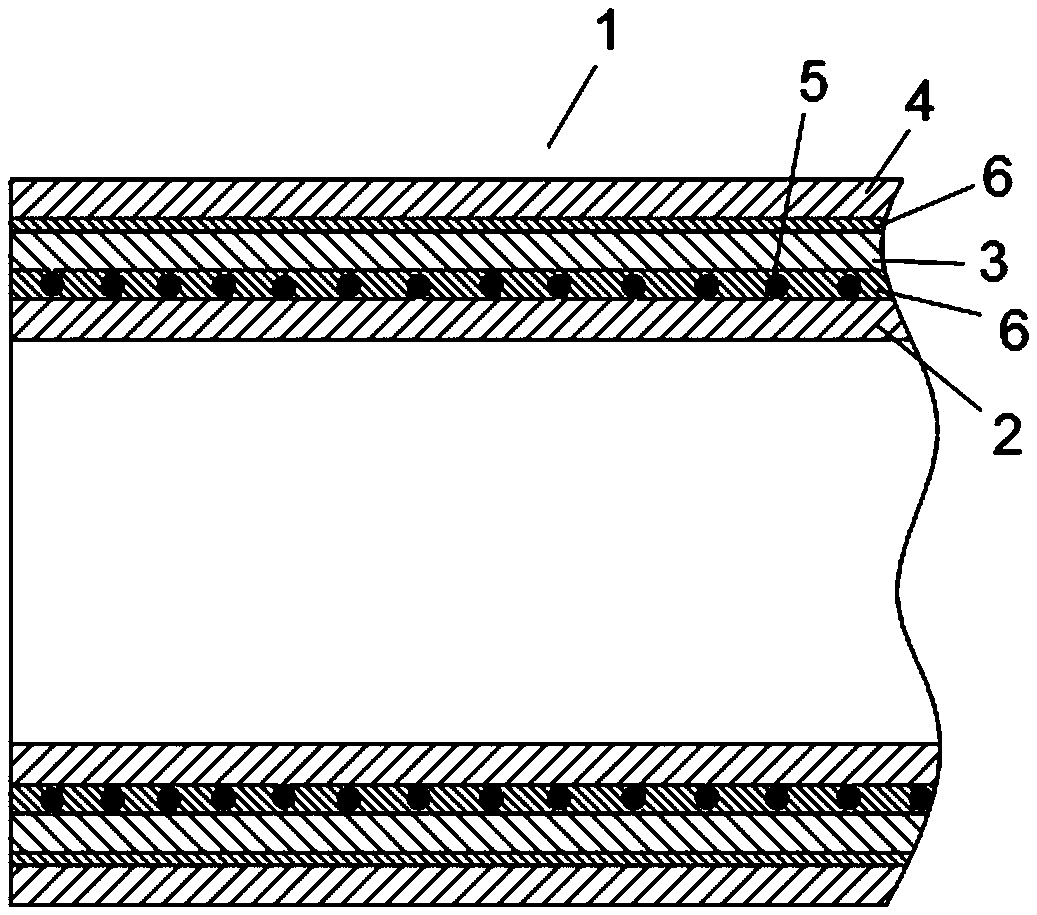

[0010] Such as figure 1 As shown, the present invention provides a rubber-plastic trachea, comprising a tube body 1, the tube body 1 is respectively provided with a rubber layer 2, a polyester layer 3, a plastic layer 4 from the inside to the outside, the polyester layer 3 and the rubber layer A diagonally wound metal wire 5 is arranged between the 2, and the rubber layer 2 and the polyester layer 3, and the plastic layer 4 and the polyester layer 3 are bonded by an adhesive layer 6.

[0011] Preferably, the material of the plastic layer 4 is PVC, and the metal wire 5 is stainless steel wire. The material of the plastic layer 4 can also be formed by adding PE, PP, etc. to PVC, and the rubber layer 2 is formed by mixing nitrile rubber and isoprene rubber.

[0012] The invention is resistant to high pressure, low temperature and high temperature, has good strength, is not easy to wear, and has a long service life.

[0013] The above is only a preferred embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com