Circular mirror frame

A mirror frame, circular technology, applied in the field of auto parts, can solve the problems of affecting the driving safety of the driver, large error of the rear view mirror, inability to adjust, etc., and achieve the effects of easy mirror assembly, high assembly precision and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings.

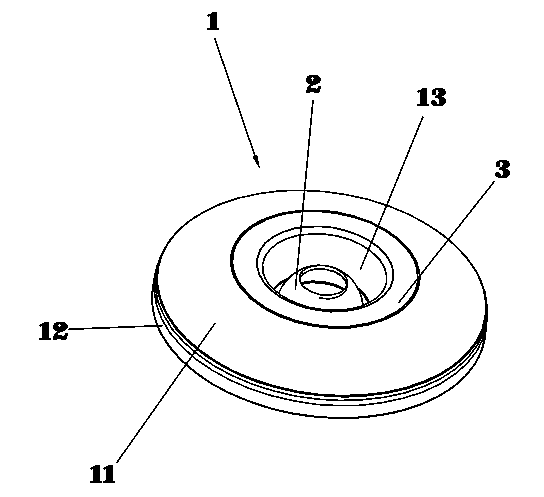

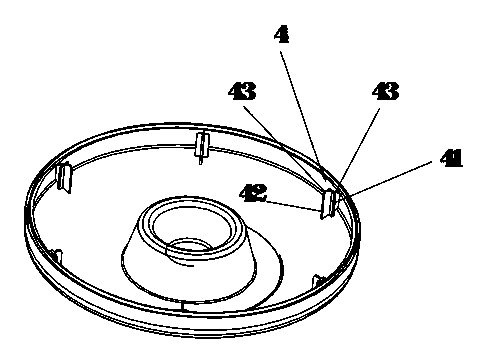

[0012] like Figure 1-2 As shown, a circular mirror frame includes an outer frame cover 1, and the outer frame cover 1 includes a truncated cone-shaped cover 11 and a sleeve 12 located at the bottom of the cover 11 and fixedly connected thereto. The middle part of the housing is provided with an inwardly recessed cavity 13, and a boss 2 is arranged inside the cavity 13, and a notch 3 for embedding a mirror surface is provided on the periphery of the cavity 13 on the casing 11. Located inside the casing 11 is a rib 4 for strengthening the joint strength between the casing 11 and the sleeve 12), the rib 4 is provided with a transverse rib 41 and a longitudinal rib 42, and the transverse rib 41 and the longitudinal rib 42 Staggered and connected to the casing 11 and the sleeve 12 at the same time. The longitudinal rib 42 is provided with an obliquely downward chamfered su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com