Repair mortar for concrete member and preparation method thereof

A technology for repairing mortar and concrete, applied in the field of cement-based mortar, can solve the problems of reducing the bonding strength and mechanical strength of repairing mortar, shrinking and cracking of repairing mortar, and excessively fast water loss, so as to improve volume stability and reduce water-to-binder ratio. , Improve the effect of sag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: be used for the repair mortar of concrete component, specifically adopt following method to prepare, comprise the steps:

[0043] S1 admixture: Take 418.5kg of cement, add 28kg of silica fume, 23.5kg of expansion agent, 23.5kg of quick-setting agent, 28.2kg of rubber powder, 0.94kg of defoamer and 9.4kg of shrinkage-reducing polycarboxylate superplasticizer, mix well, Prepare powder material.

[0044] Preparation of S2 mortar: Take 90kg of water, pour it into a mixing pot, add powder materials, stir at a speed of 70 rpm for 120s, add 500kg of dry sand with a particle size of 0.15-0.3mm, and continue stirring for 120s to prepare a mortar for concrete Component repair mortar.

Embodiment 2

[0045] Embodiment 2: be used for the repair mortar of concrete component, specifically adopt following method to prepare, comprise the steps:

[0046] S1 admixture: Take 418.5kg of cement, add 28kg of silica fume, 23.5kg of plastic expansion agent, 23.5kg of quick-setting agent, 28.2kg of rubber powder, 0.94kg of defoamer and 9.4kg of shrinkage-reducing polycarboxylate superplasticizer, and mix well , to obtain a powder material.

[0047] S2 sand mixing: Take 100kg of sand with a particle size of 0.075-0.15mm, add 150kg of sand with a particle size of 0.15-0.3mm and 250kg of sand with a particle size of 0.3-0.6mm, the sand is dry sand, and mix evenly to obtain a gradation sand.

[0048] S3 mortar preparation: Take 90kg of water, pour it into a mixing pot, add powder materials, stir at a speed of 70 rpm for 120s, add graded sand, and continue stirring for 120s to prepare repair mortar for concrete components.

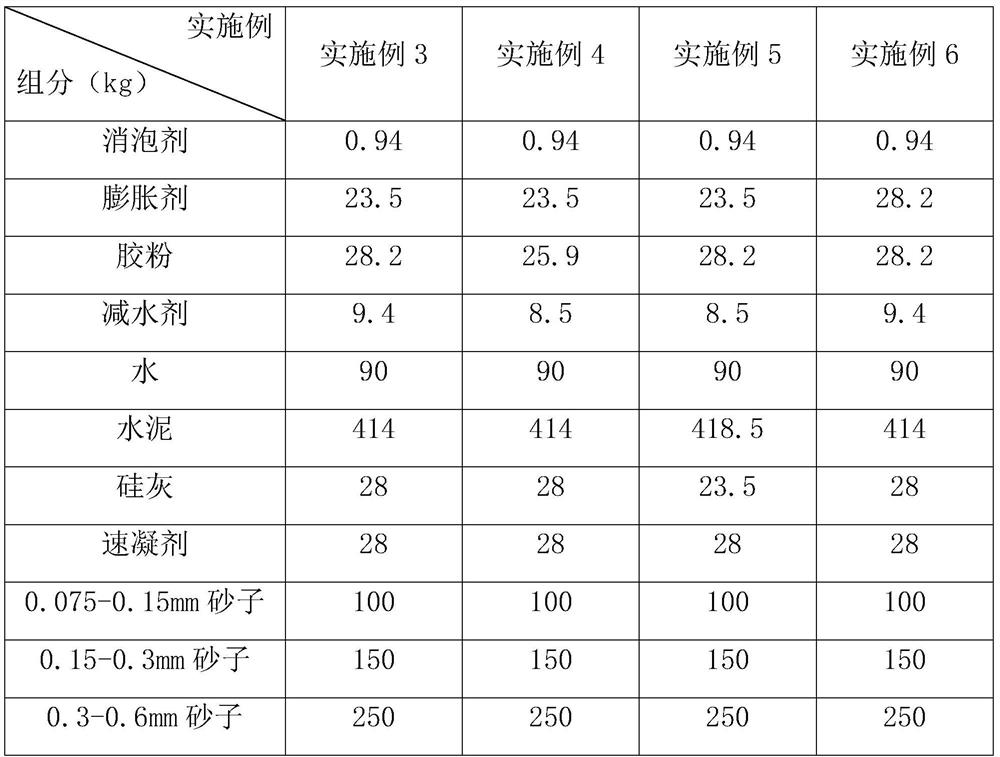

Embodiment 3-6

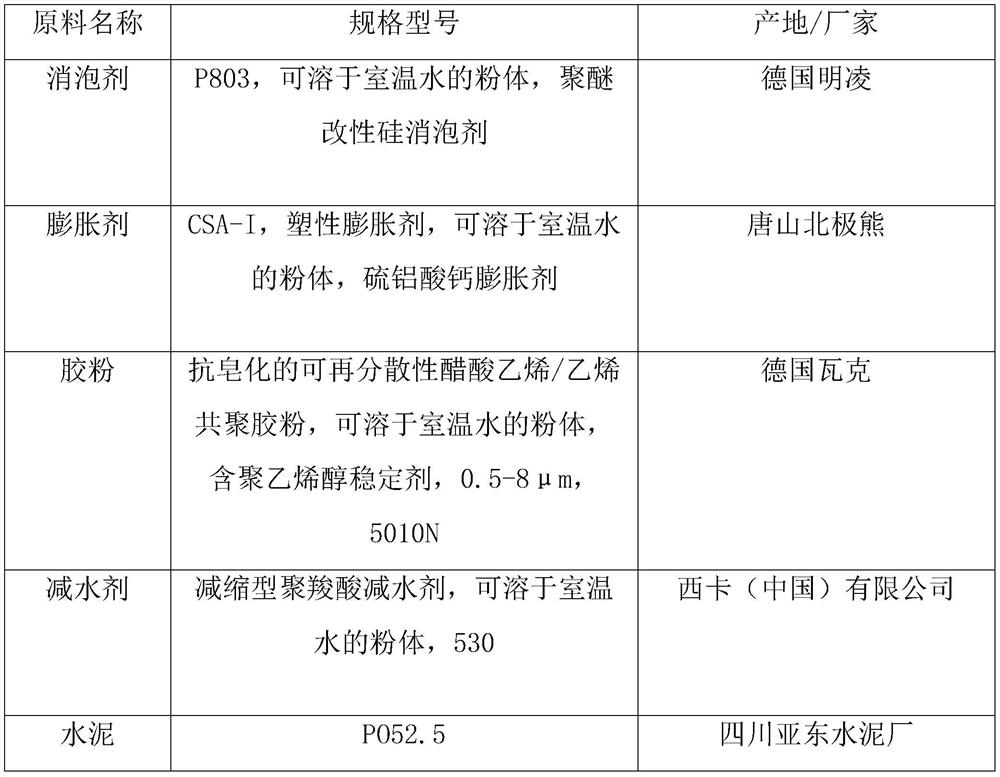

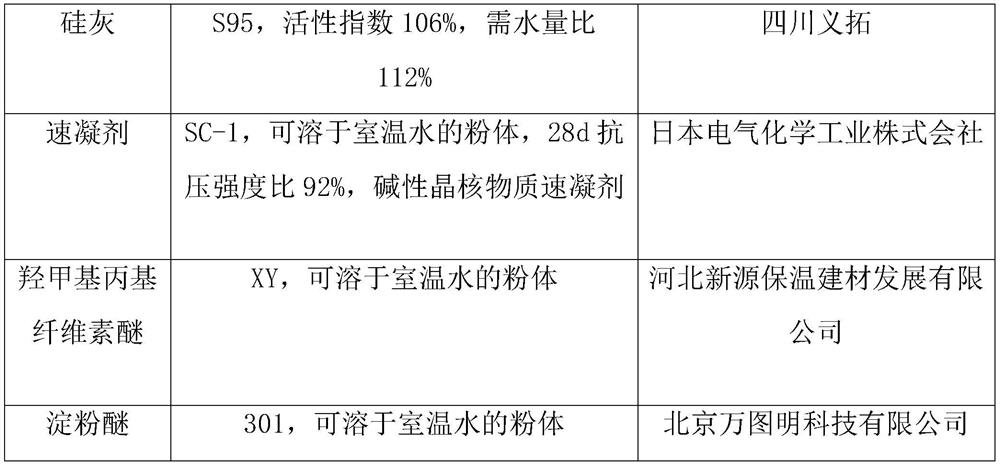

[0050] The difference between Example 3-6 and Example 2 is that the addition amount of each raw material in Example 3-6 is different, and the others are consistent with Example 2. The addition amount of each raw material in Example 3-6 is shown in Table 2.

[0051] The addition of each raw material of table 2 embodiment 3-6

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com