High-pressure atomizing system for laboratory

A high-pressure spray, laboratory-use technology, applied in the field of thermal experiments, can solve the problems of increasing the overall energy consumption of the laboratory, difficult adjustment and control of temperature indicators, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

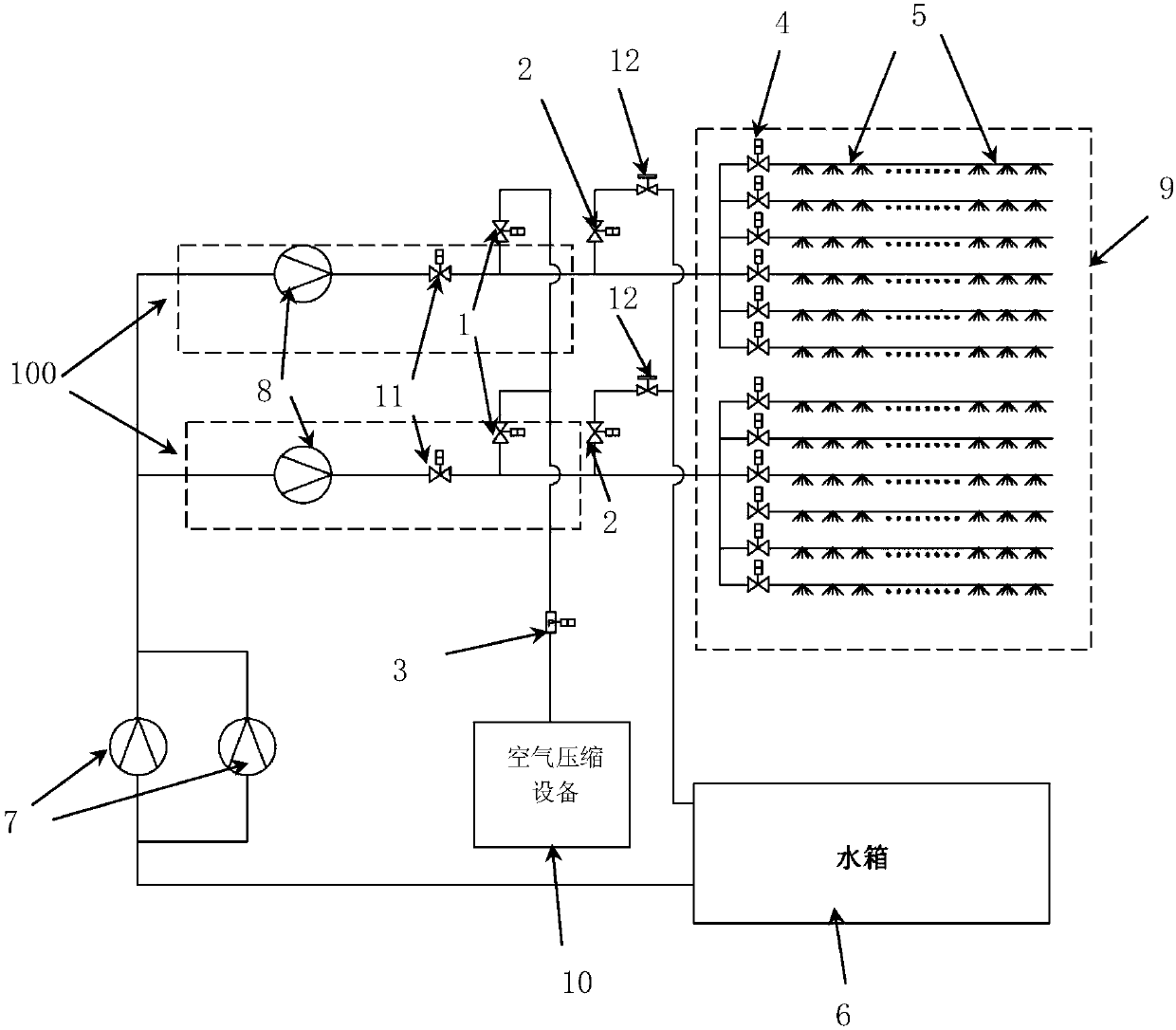

[0038] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] see figure 1 , the present invention provides a laboratory high-pressure spraying system, comprising a water tank 6, the water outlet at the lower left end of the water tank 6 communicates with the water inlets of two water supply pumps 7 (through hollow pipelines);

[0040] The water outlets of each of the water supply pumps 7 are connected to two water pressurization pipelines 100 after converging;

[0041] The water outlet of each water boosting pipeline 100 is connected with a plurality of atomizing humidification pipelines, and the water boosting pipeline 100 is used to pressurize the water from the water supply pump 7 and then output it to The atomizing humidification pipeline is used for spraying.

[0042] In the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com