Backmixing reduction control device for continuous operation of slurry reactor

A control device and reactor technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as influence, poor operation effect, serious back-mixing phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

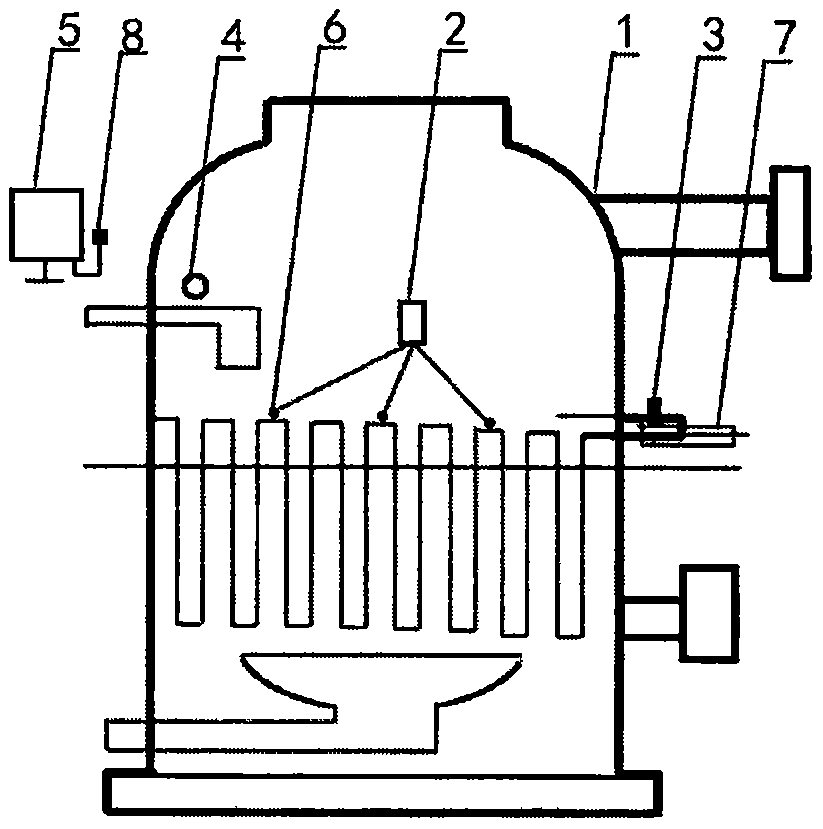

[0012] Embodiment: as shown in the accompanying drawing. The slurry reactor continuous operation back-mixing reduction control device includes a body (1), on which a temperature sensing module (2), a material sensing module (3), an information receiving module (4), and a management module ( 5), during operation, the temperature sensing module (2) senses the temperature change of the body material passing through the parts, the material sensing module (3) senses the material content of the body pipeline, the information receiving module (4) receives relevant information, and the management module (5) Process aggregated information.

[0013] The continuous operation back-mixing reduction control device of the slurry reactor is equipped with a rapid cooling module (6) on the temperature sensing module (2), and performs cooling treatment on the high-temperature pipeline according to the sensed temperature value.

[0014] The continuous operation back-mixing reduction control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com