Adjustable blade base for element foot cutter

A cutting machine, adjustable technology, applied in the field of cutting machine, can solve problems such as single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

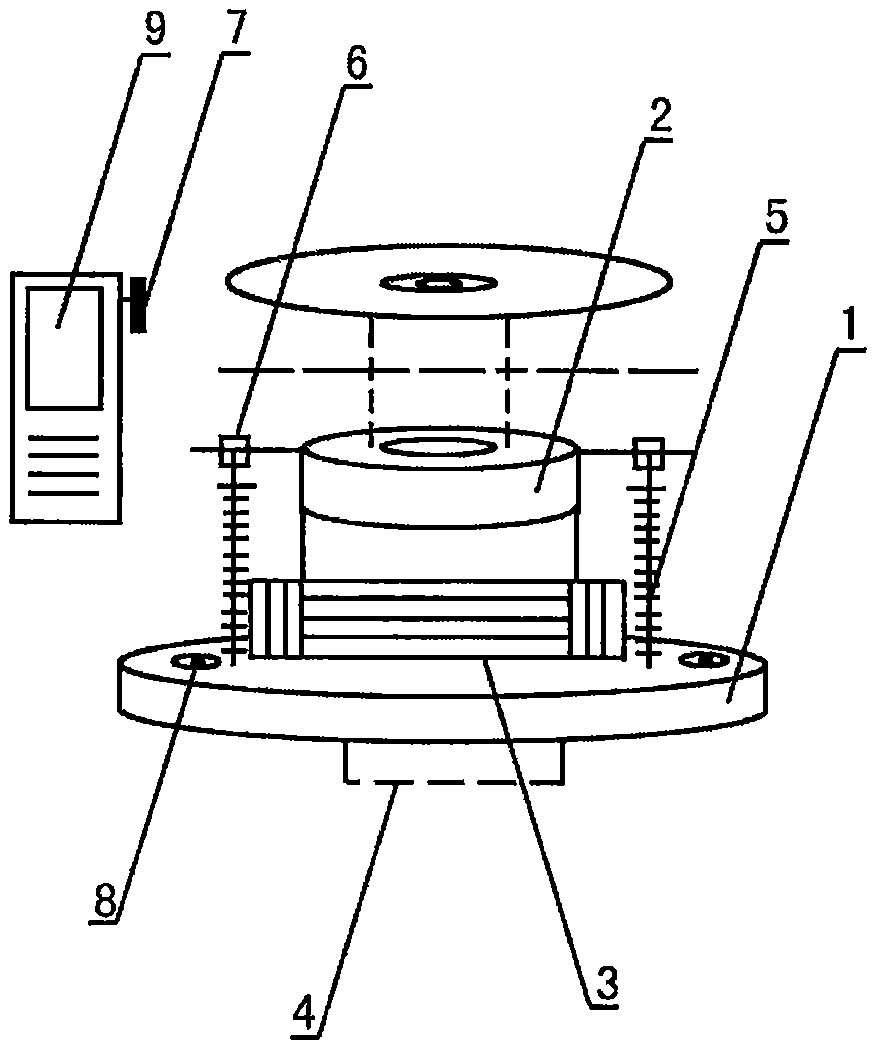

[0012] Embodiment: as shown in the accompanying drawing. An adjustable blade base of a component cutting machine, including a base (1), the base (1) is designed as a multi-layer disc structure, the upper end is equipped with a positioning plate device (2) with adjustable inclination, and the middle part is equipped with a pneumatic lift The column (3) is connected to the air source through the connecting port (4) at the bottom, and the detection components of the structure such as the height measuring bracket (5) and the levelness monitoring device (6) are arranged on both sides of the base (1), and the blade is locked on the On the positioning plate device (2), adjust the height and inclination of the corresponding parts of the base (1) according to the length of the cutting leg required by the component and the particularity of the cutting part to perform targeted cutting.

[0013] An adjustable blade base of a component cutting machine is provided with a prompting device (7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com