Platform structure for assembling and dissembling carrying vehicle

A platform and vehicle technology, applied in the field of platform structure, can solve the problems of no load-bearing legs, narrow trestle passing surface, no side unloading function, etc., and achieve the effect of fast operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

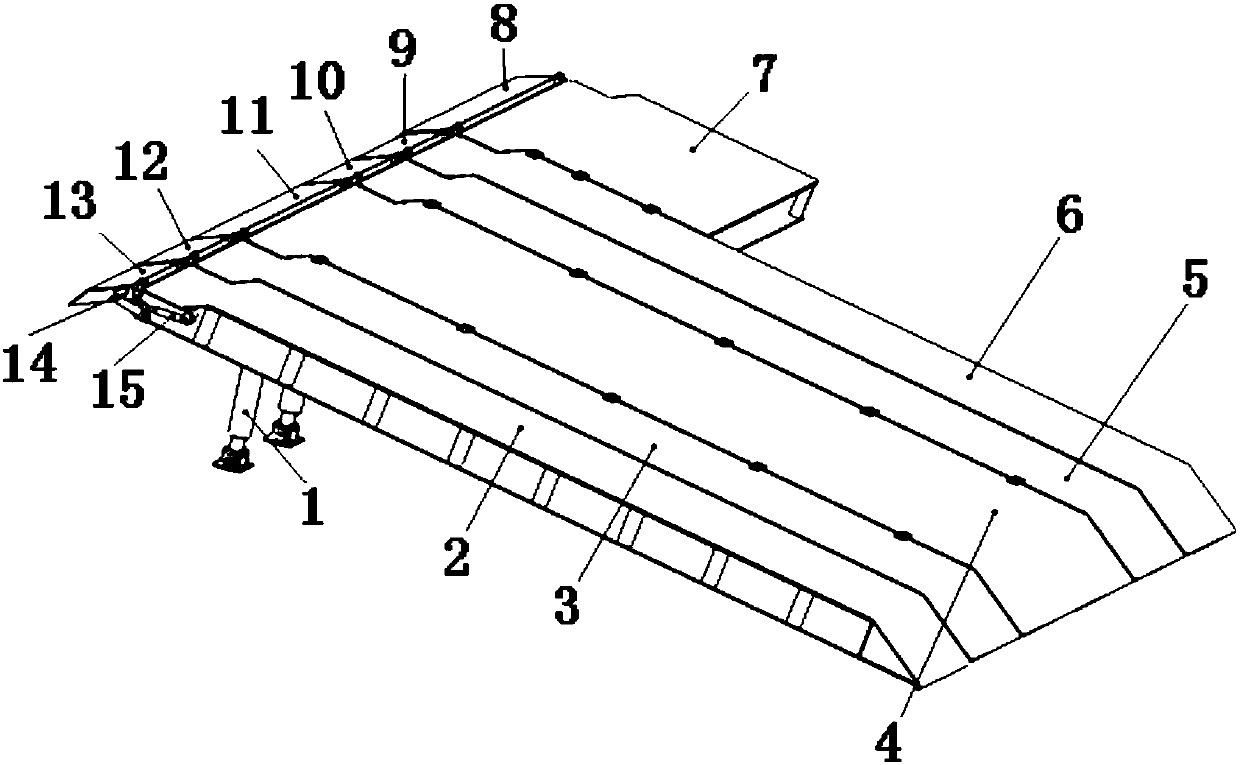

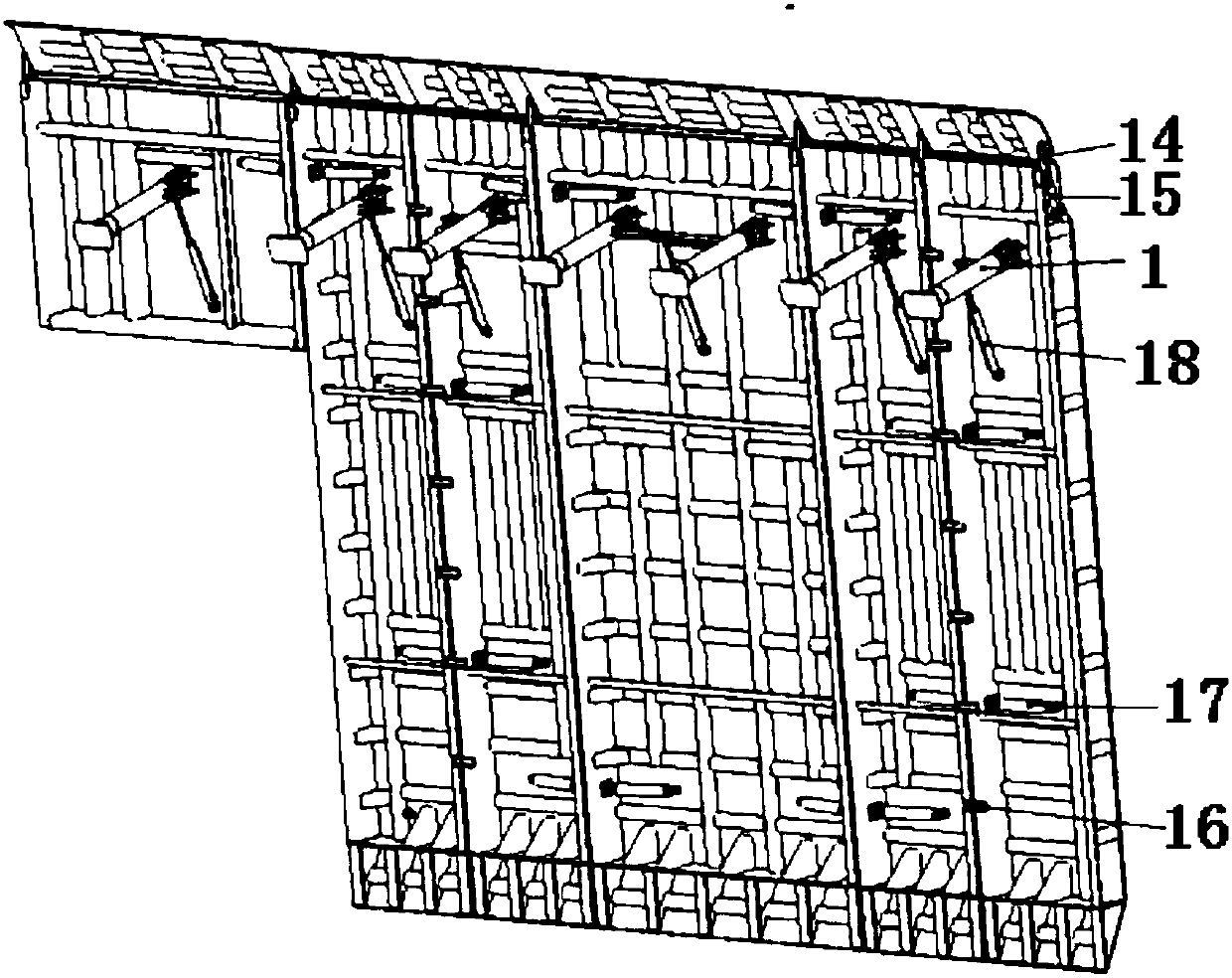

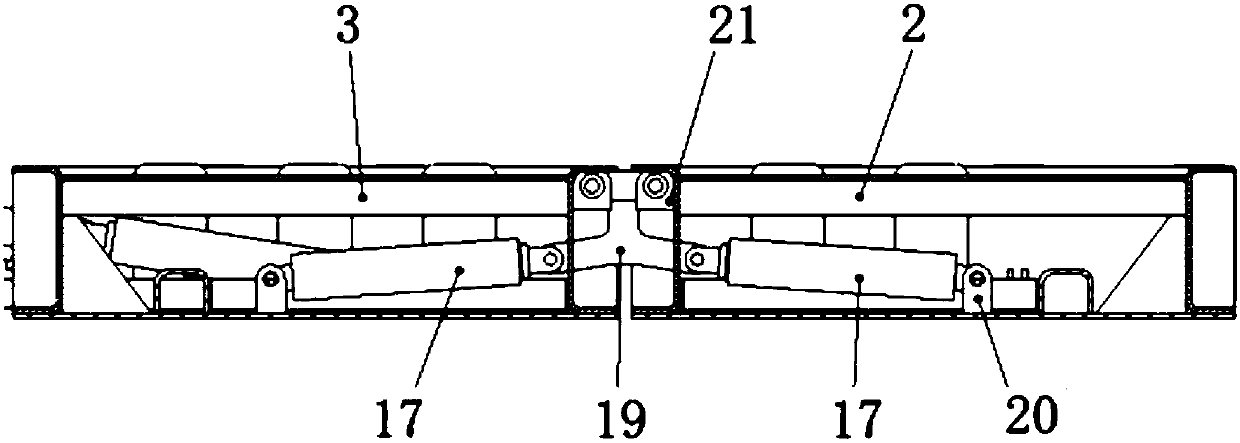

[0027] Such as figure 1 As shown, it is a platform structure for loading and unloading vehicles, including folding plate one 2 and folding plate two 3, folding plate two 3 and folding plate three 4, folding plate three 4 and folding plate four 5, folding plate four 5 and folding plate Plate five 6, foldable plate five 6 and foldable plate six 7 are all respectively connected by hinge mechanisms, and are controlled by two telescopic oil cylinders so as to realize the functions of folding and unfolding among the six foldable plates. Overlapping board six 8 and folding board six 7, overlapping board five 9 and folding board five 6, overlapping board four 10 and folding board four 5, overlapping board three 11 and folding board three 4, overlapping board two 12 and Folding plate two 3, lapping plate one 13 and folding plate one 2 are connected by folding mechanism, and the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com