Patents

Literature

33results about How to "Achieve width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

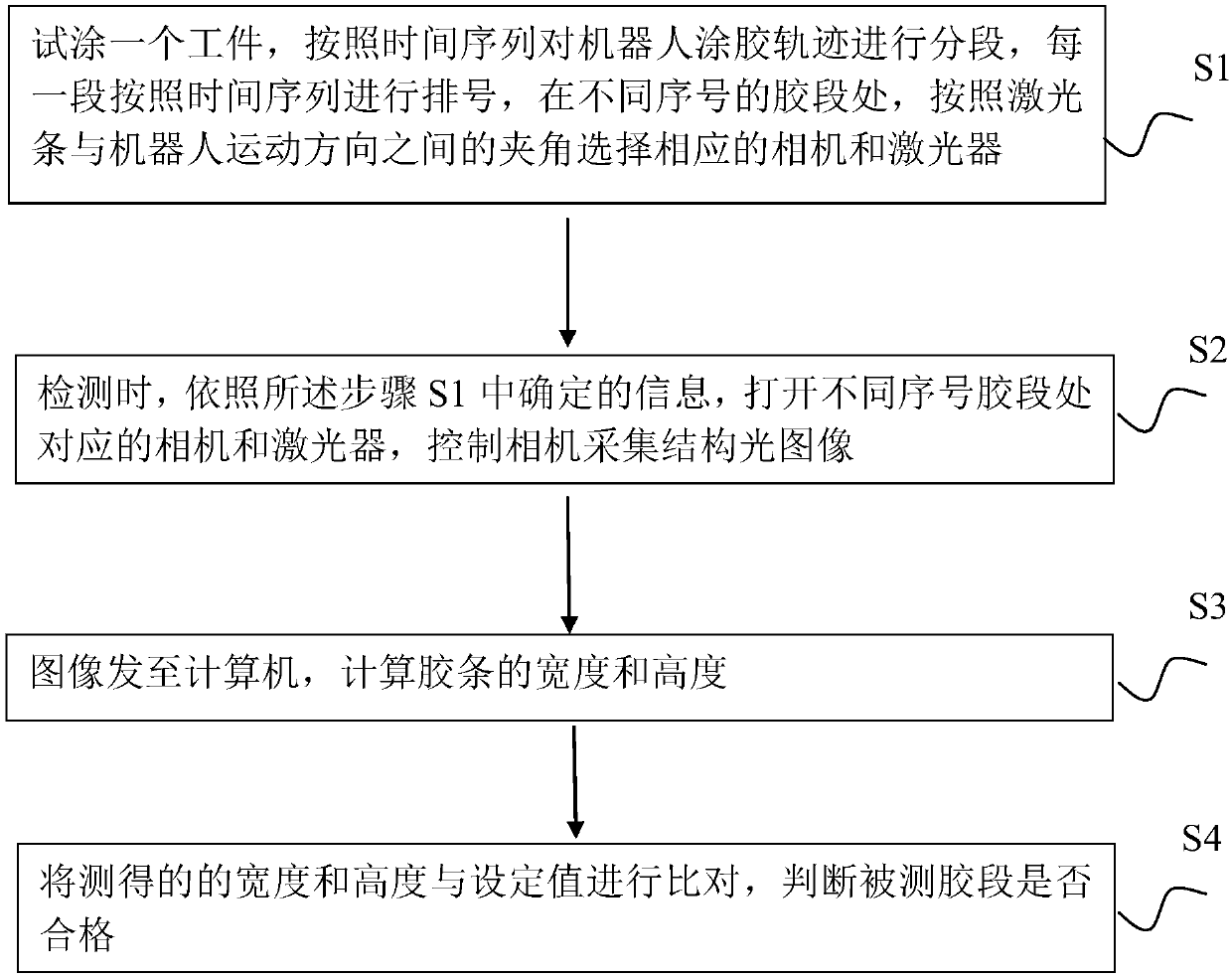

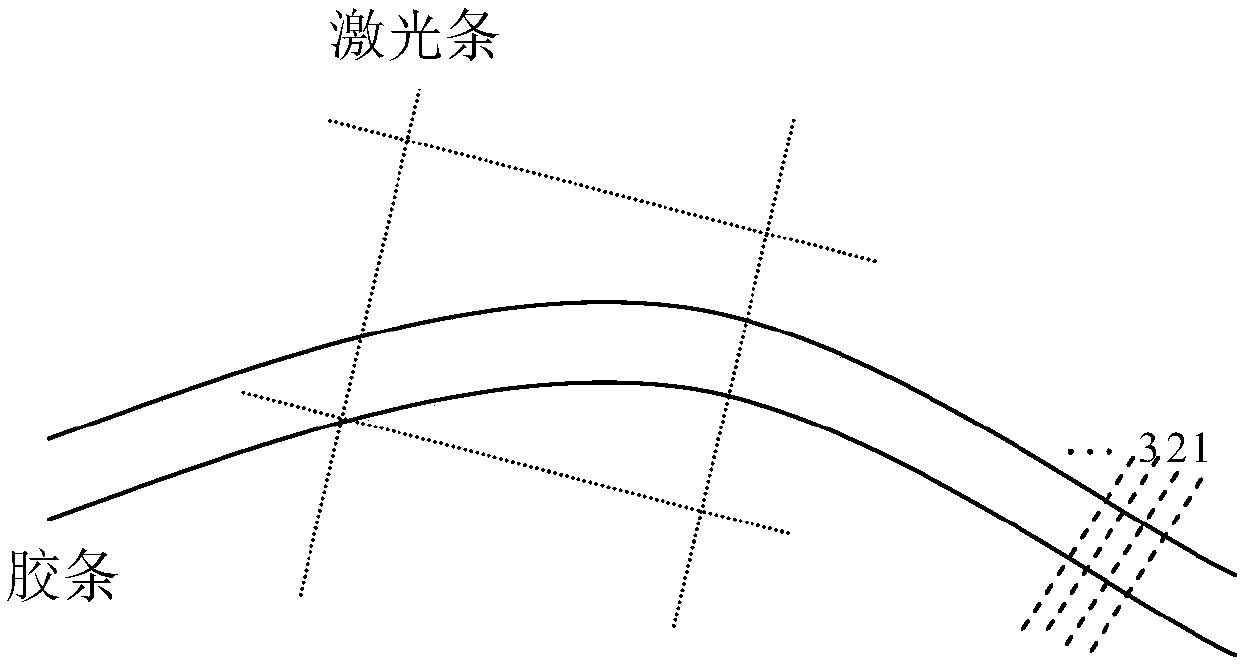

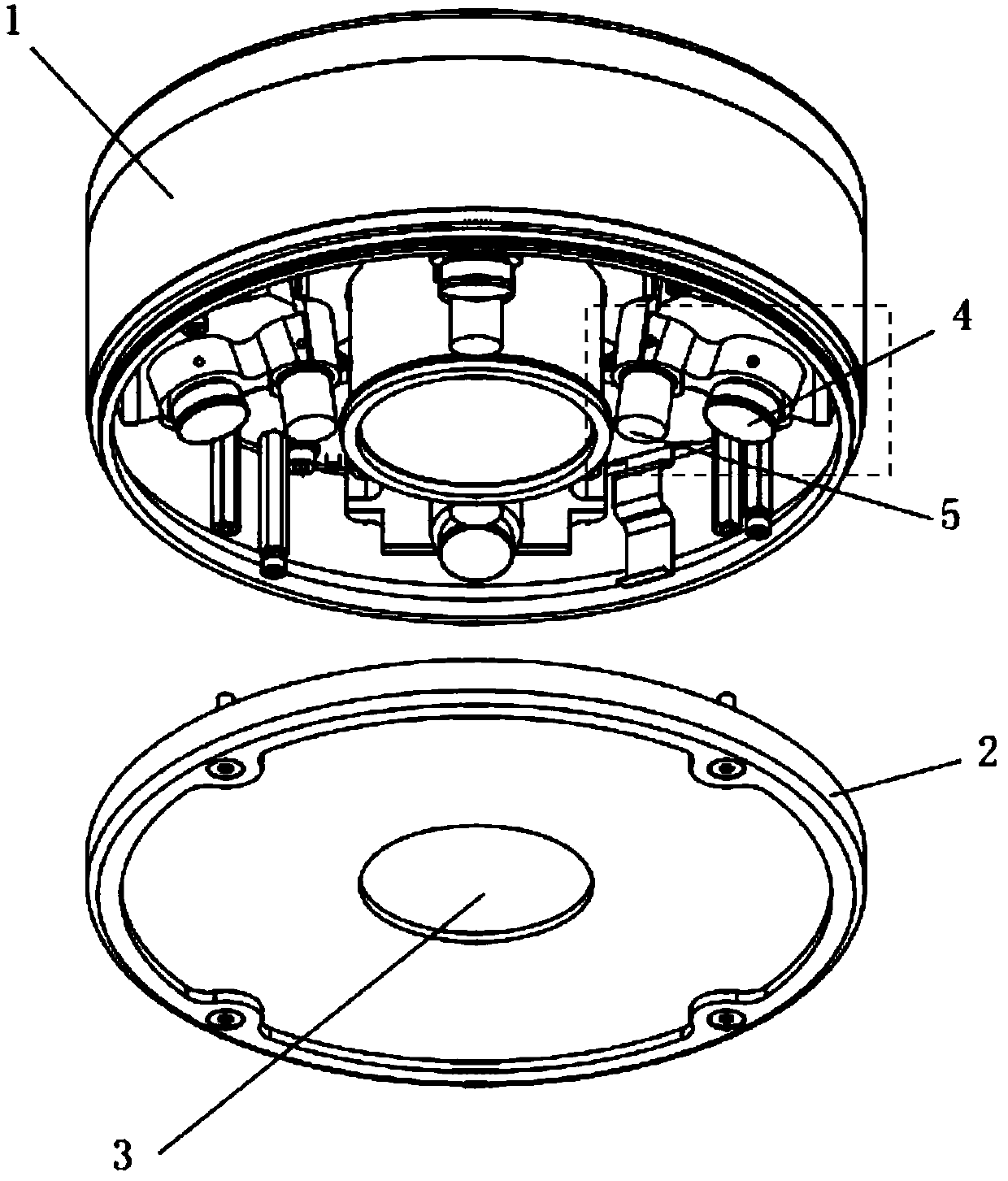

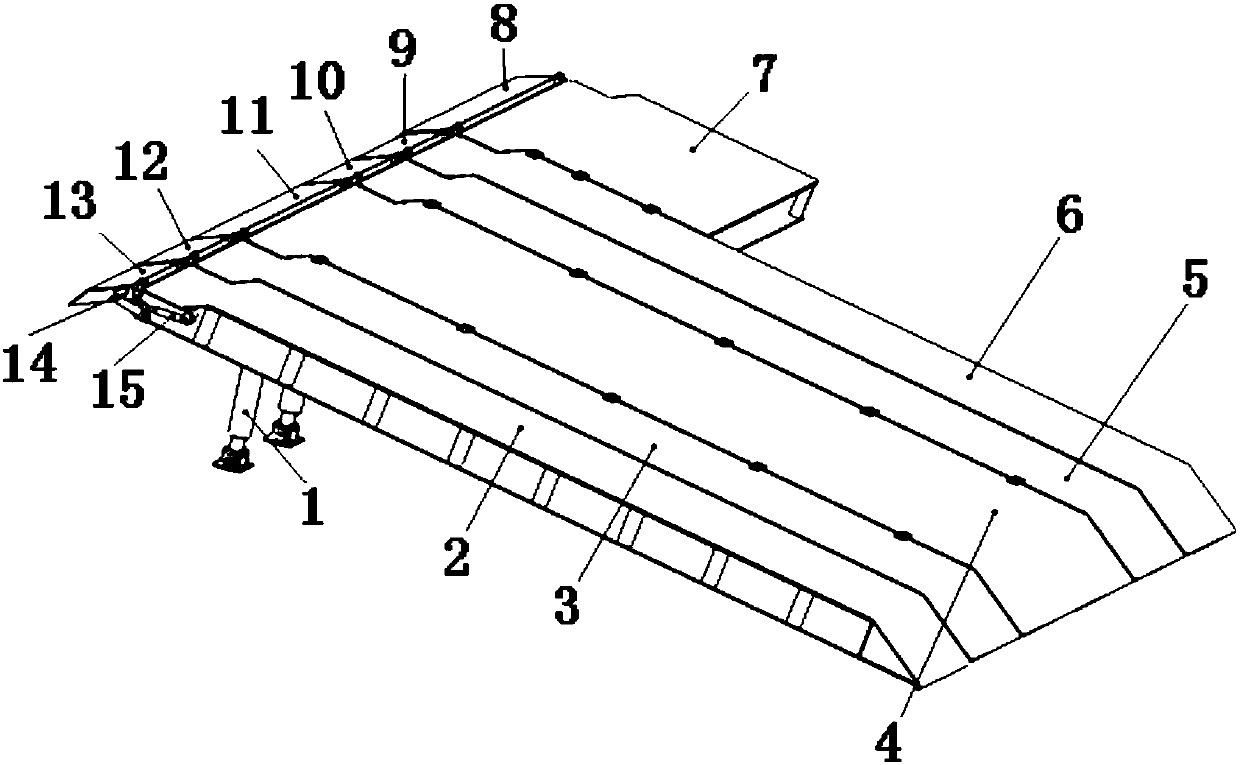

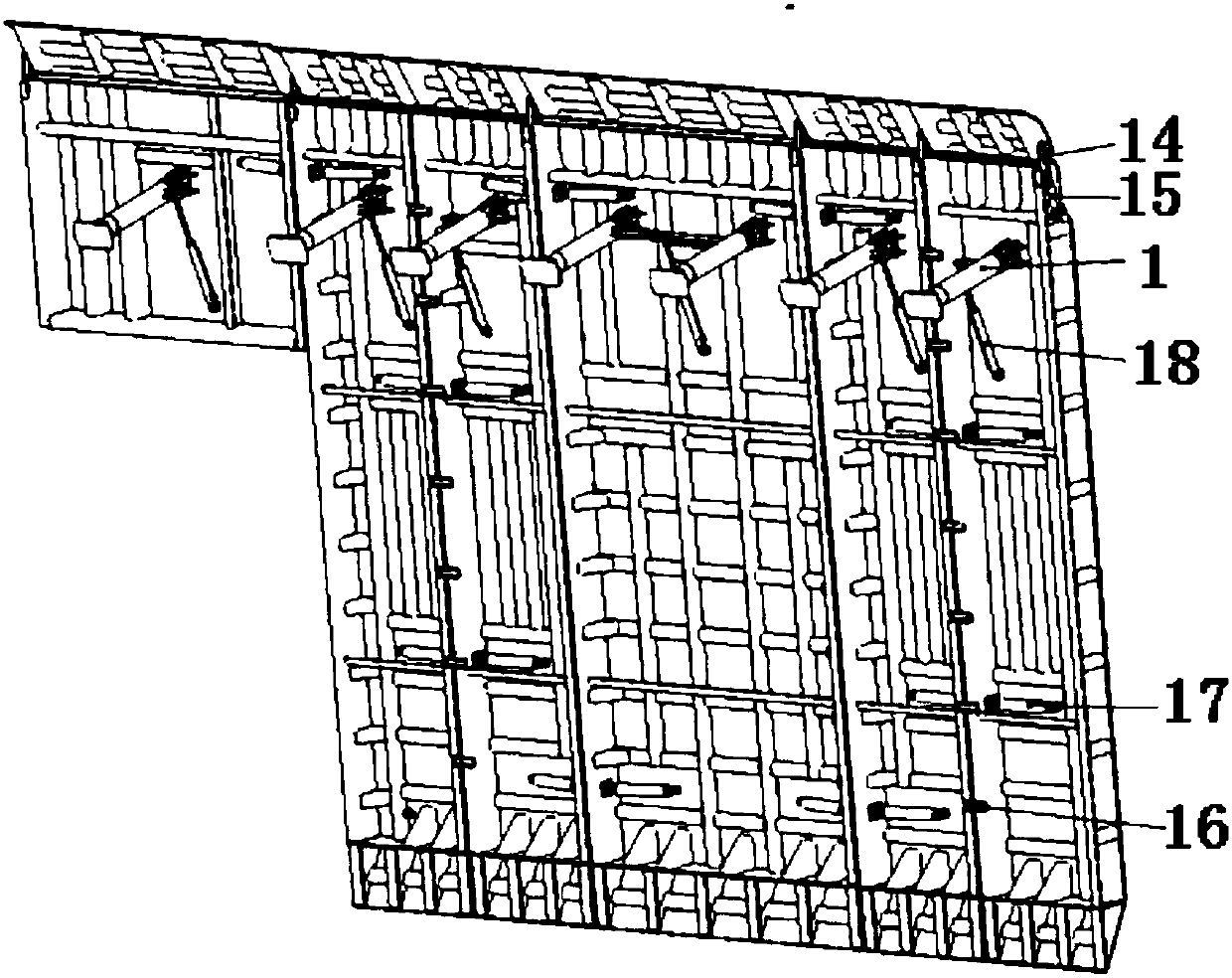

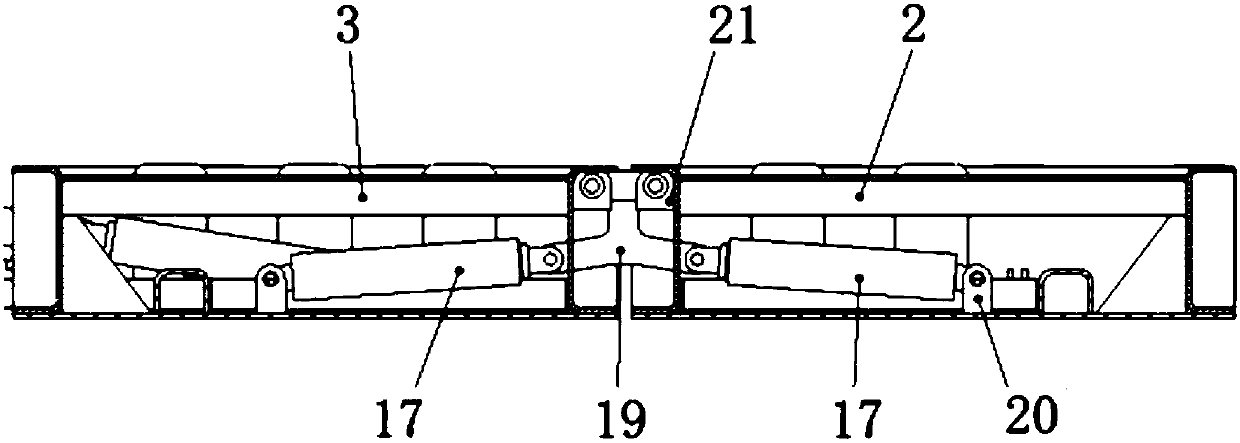

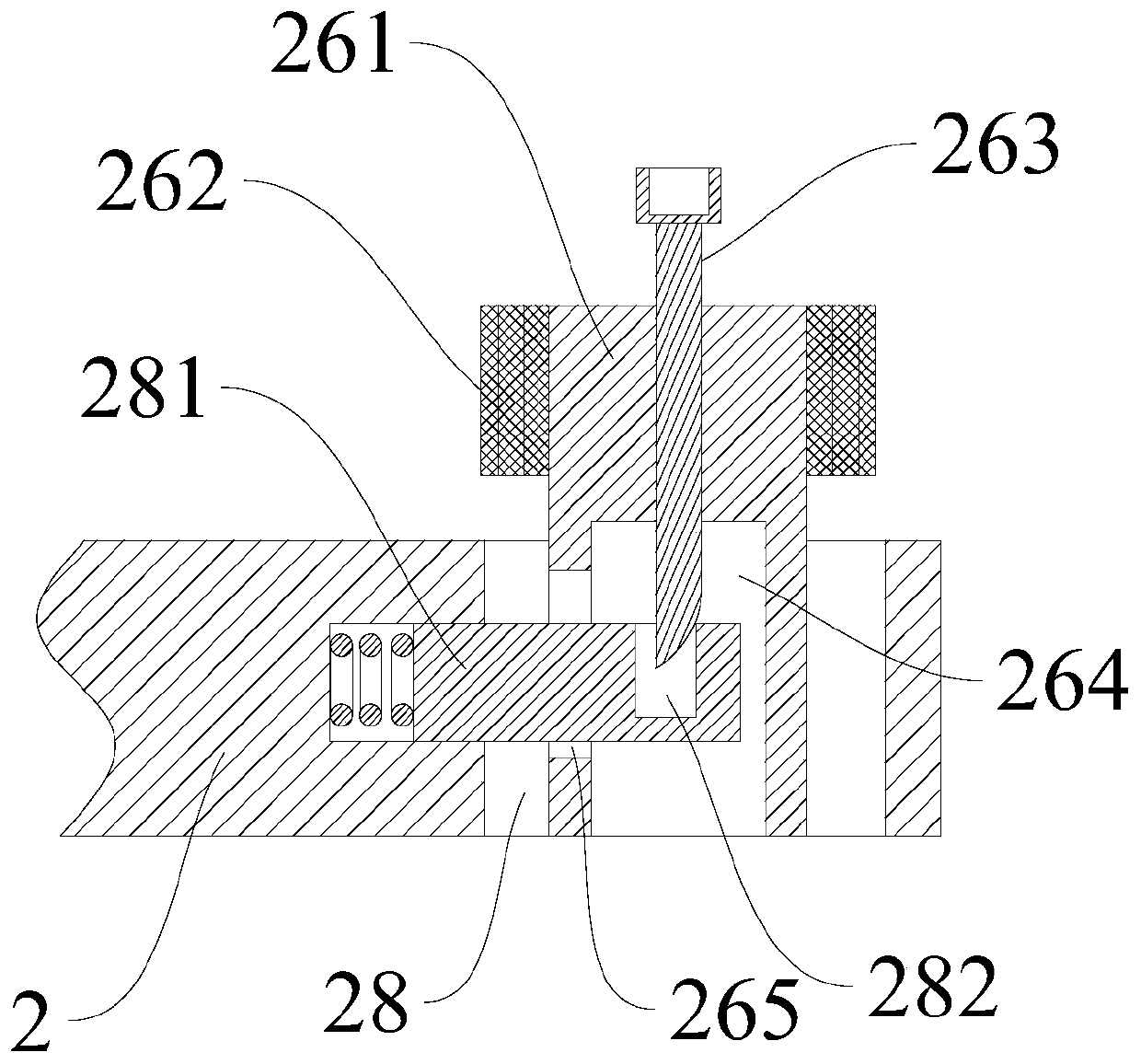

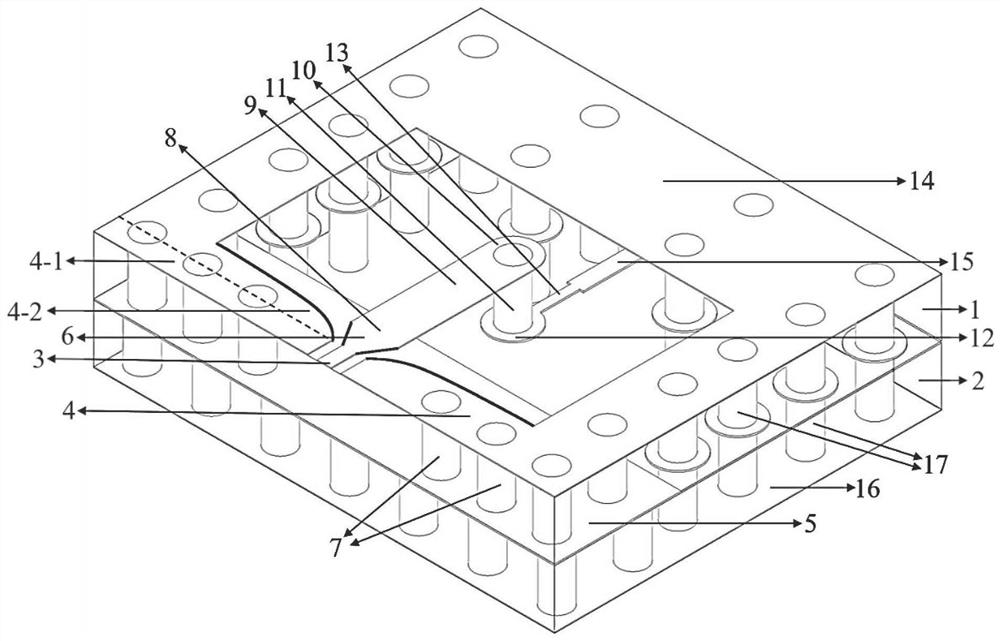

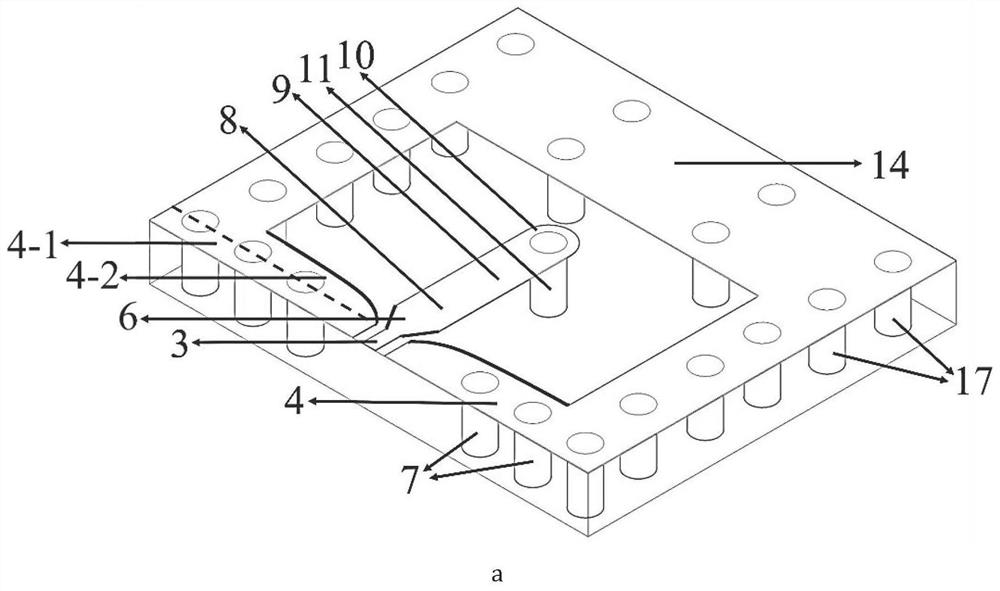

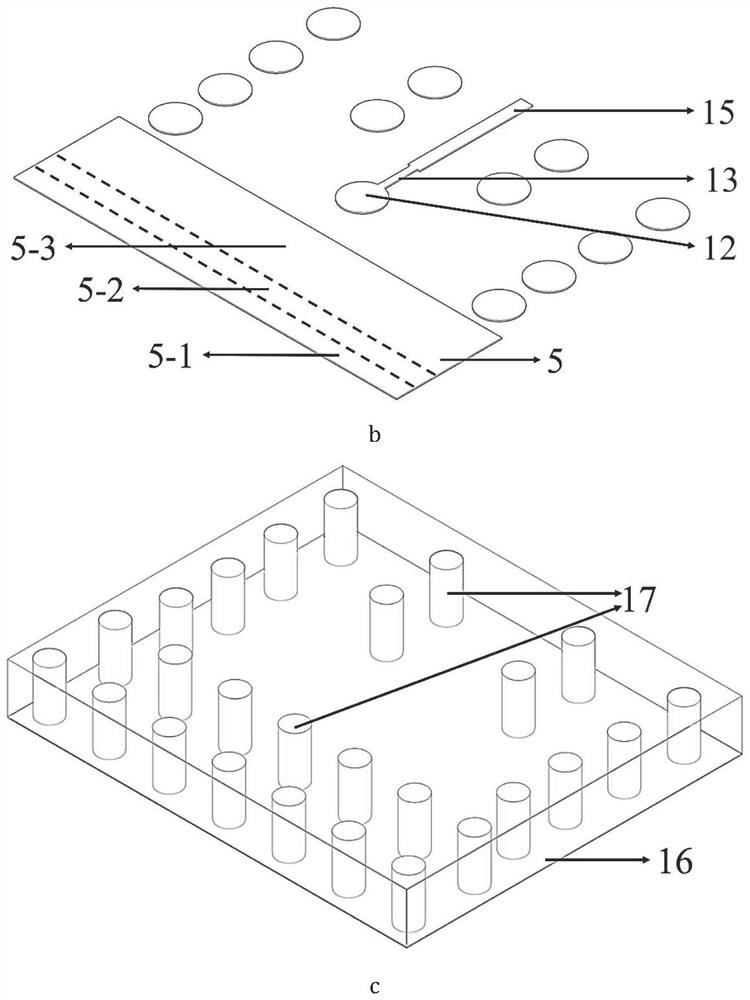

Three-dimensional real-time gluing detection method and device

PendingCN107726985AComprehensive detection contentRealize detectionUsing optical meansAlgorithmAdhesive

The invention discloses a three-dimensional real-time gluing detection method and device for detecting the width, height and continuity of adhesives in a robot gluing process in real time. The three-dimensional real-time gluing detection method is characterized by comprising the steps of first of all, carrying out a teaching process, subdividing and quantizing glued adhesive tape into different adhesive tape segments, ranking the adhesive tape segments, selecting started cameras and started lasers which correspond to the adhesive tape segments with different sequence numbers, and when detection is carried out, calculating the width and height of the adhesive tape segments to be measured based on a structured light image three-dimensional measurement principle to judge whether or not the glued adhesive tape is qualified. According to the gluing detection method and device, three-dimensional data of the adhesive tape is analyzed, and therefore the width and height of the adhesive tape can be calculated. Compared with an existing detection method, detection on height information of the adhesive tape is added. Besides, when the color of the adhesive tape is similar to or the same as that of a glued workpiece, the detection method of the device still can effectively analyze the quality of the adhesive tape.

Owner:ISVISION (TIANJIN) TECH CO LTD

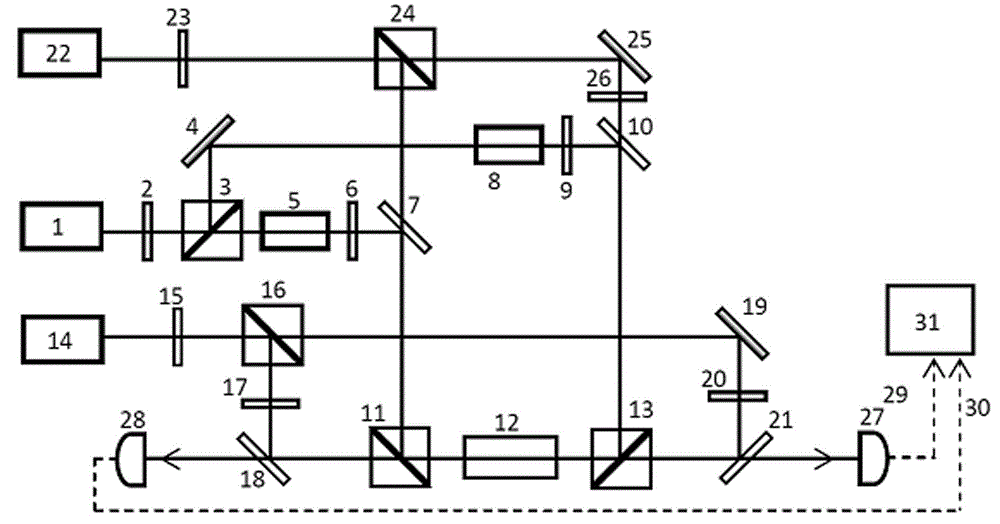

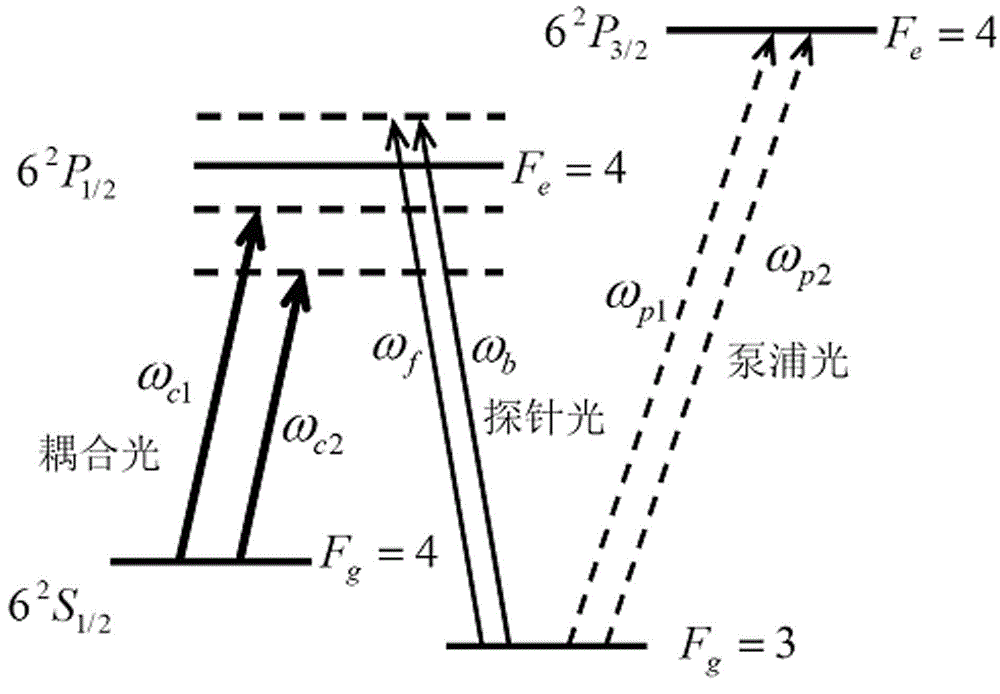

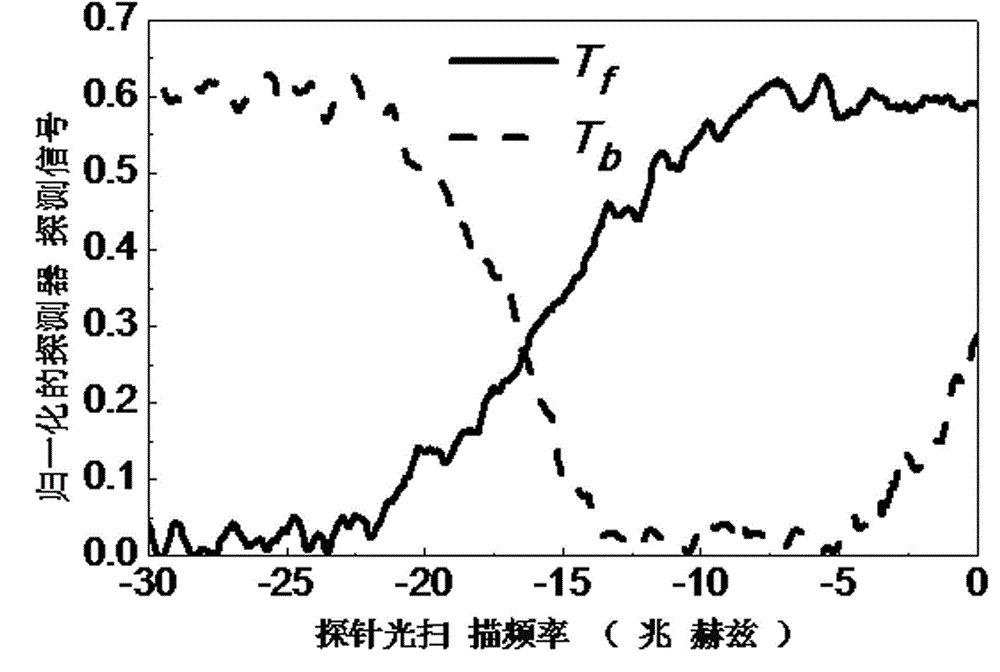

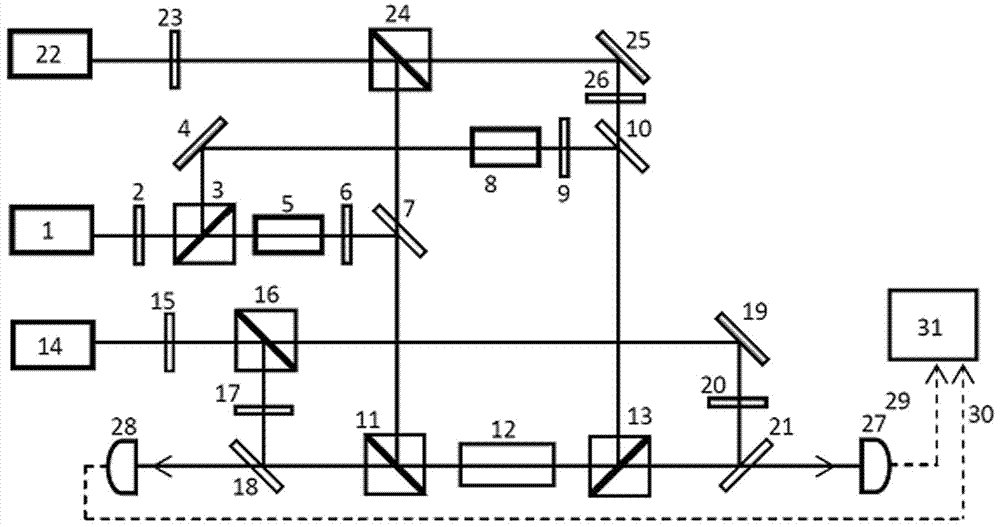

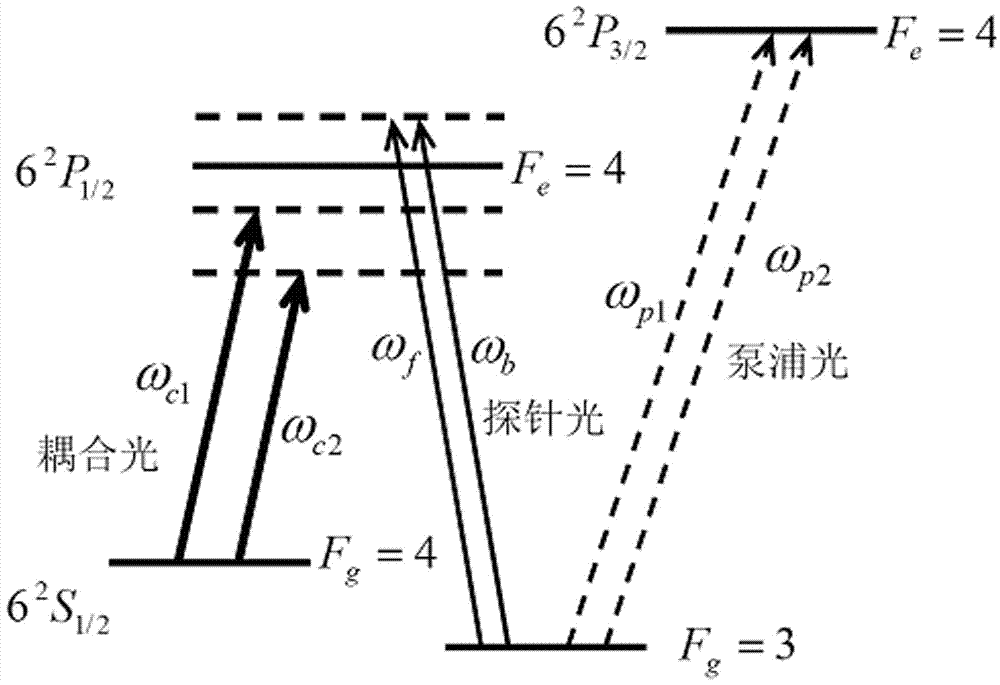

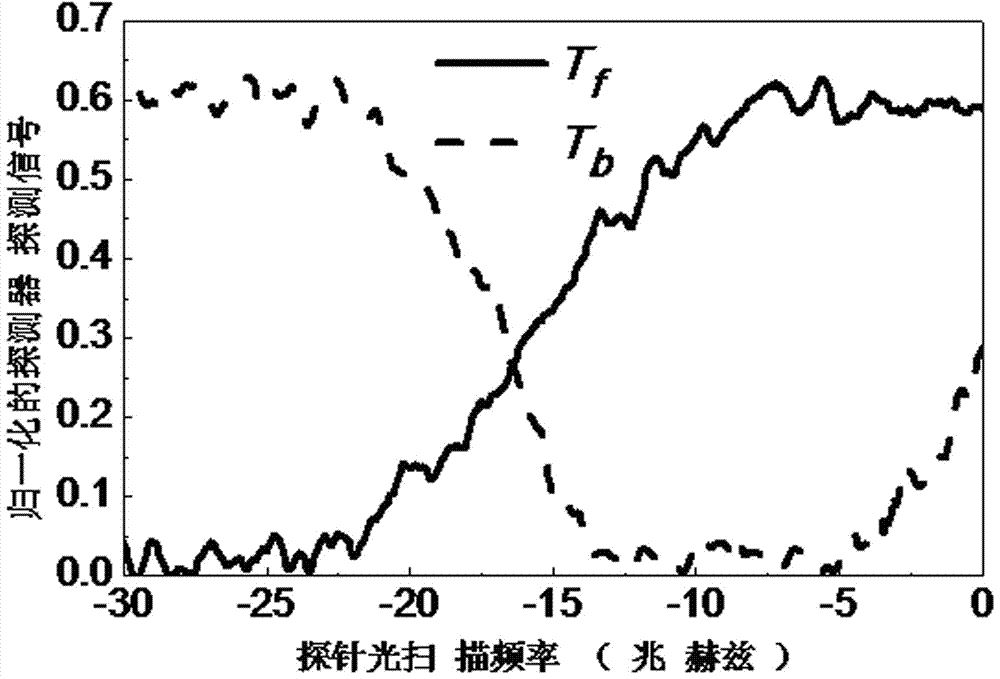

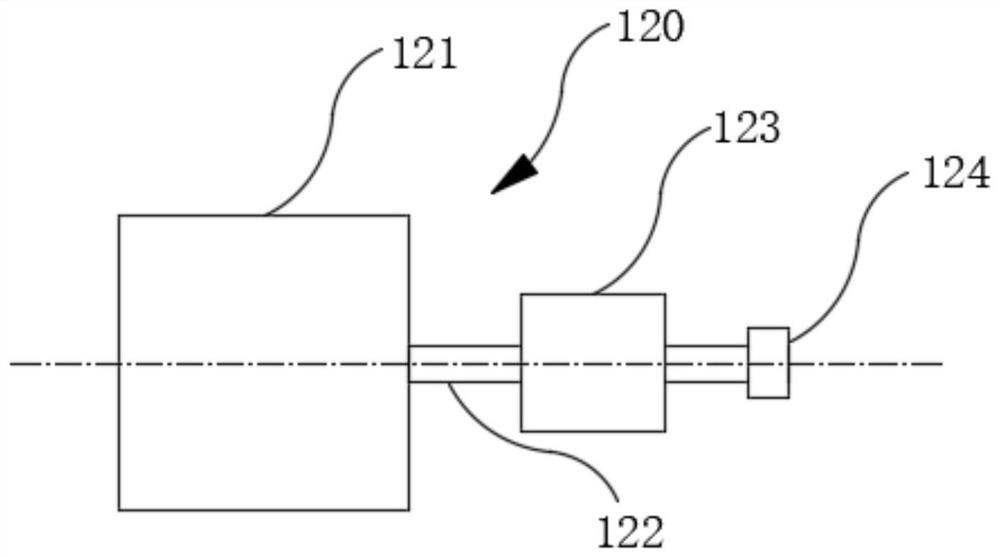

Method of realizing bidirectional optical diode and device of realizing bidirectional optical diode

ActiveCN104882783AChange positionChange widthLaser output parameters controlRefractive indexBidirectional coupling

The present invention provides a method of realizing a bidirectional optical diode and a device of realizing the bidirectional optical diode. The scheme of the present invention is that: two beams of coupling fields which are irradiated oppositely and possess a certain frequency detuning are acted on a thermokalite metal atom steam chest, so that an atomic medium generates the periodic modulation to a refractive index of the probe light, the transmission characteristic of the bidirectional incident probe light is operated and controlled effectively, and a bidirectional optical diode function possessing certain frequency interval and frequency width is realized. A frequency interval depends on the frequency detuning difference between the bidirectional coupling fields, and a frequency width depends on a Doppler effect caused by the random motion of hot atoms. Meanwhile, a pair of coherent pumping fields are introduced, the bidirectional transmission efficiency of an optical diode can be improved effectively, and an isolation ratio is not influenced. The device involved in the present invention is easy to miniaturize and integrate, can form a practical light quantum device, and can be widely used in the research fields, such as the multichannel quantum state storage, the quantum information storage, such as an tunable all-optical control optical switch, an optical reflector, etc., the quantum relay network, etc.

Owner:北京瓦科光电科技有限公司

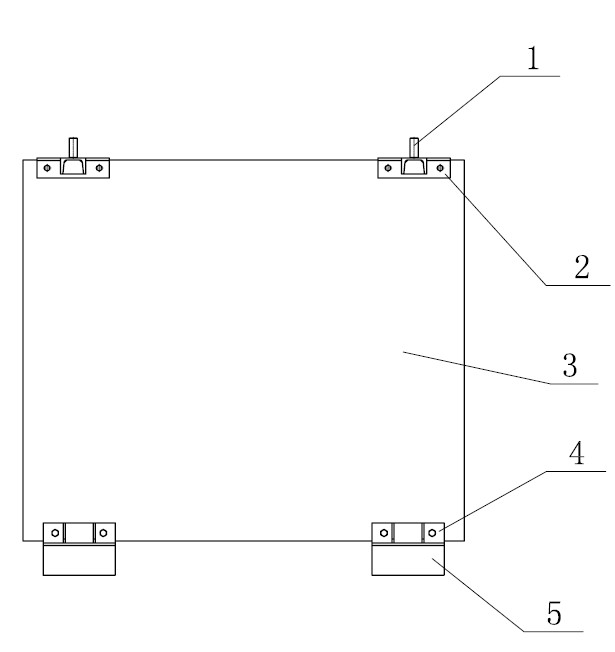

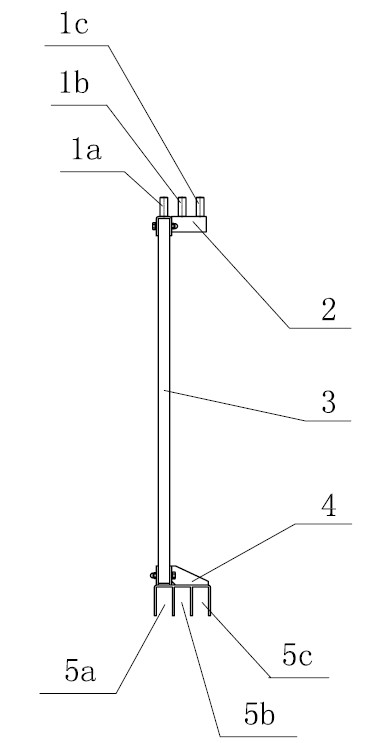

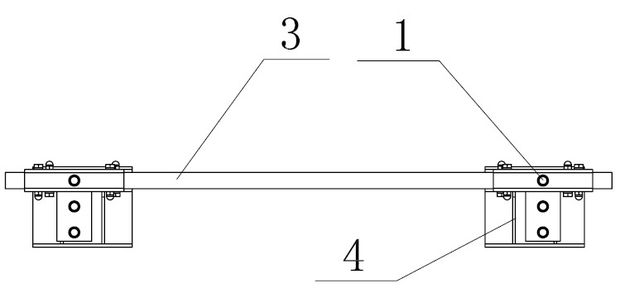

Fence structure applicable to complicated topographic structures

The invention relates to a fence structure applicable to complicated topographic structures. The fence structure comprises a fence upright column, a fence mesh and a fence pressure plate. The fence mesh comprises a plurality of transverse bars and longitudinal bars which are arranged in a mutually staggered manner, and the fence upright column is connected with the fence mesh by the fence pressure plate. The fence pressure plate comprises a plurality of connecting grooved blocks which are uniformly arranged along an extending direction of the fence upright column, and the adjacent connecting grooved blocks are connected with one another by connecting plates; each connecting grooved block comprises two fixing grooves and a fixing plate, and every two corresponding fixing grooves are connected with each other by the corresponding fixing plate. According to the technical scheme, the fence structure applicable to the complicated topographic structures has the advantages that a fence can be rotationally mounted according to topographic requirements and accordingly can effectively cling to the topography, the cost can be saved, and a protective effect can be improved.

Owner:ZHANGJIAGANG GOLDNET FENCING SYST

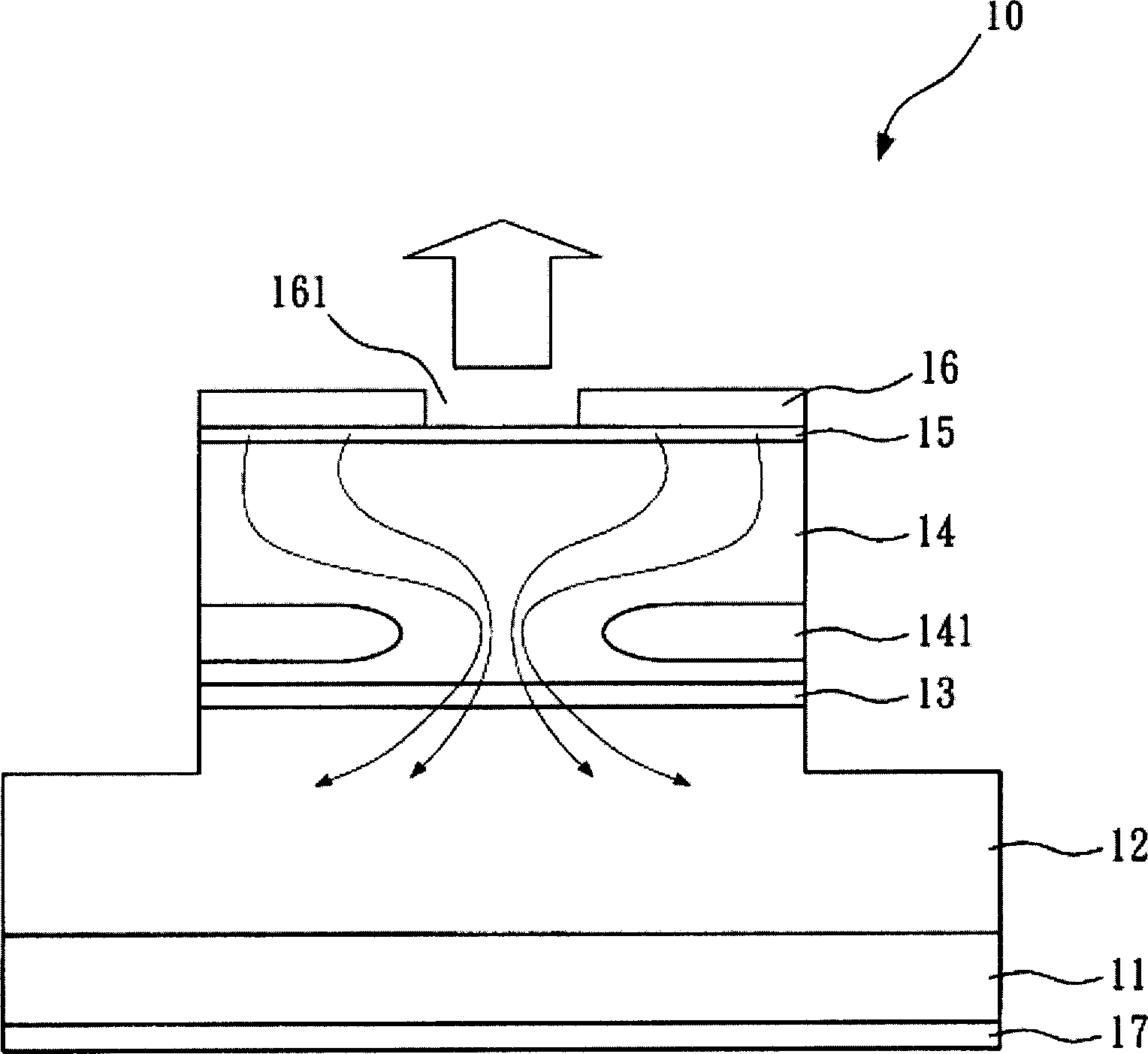

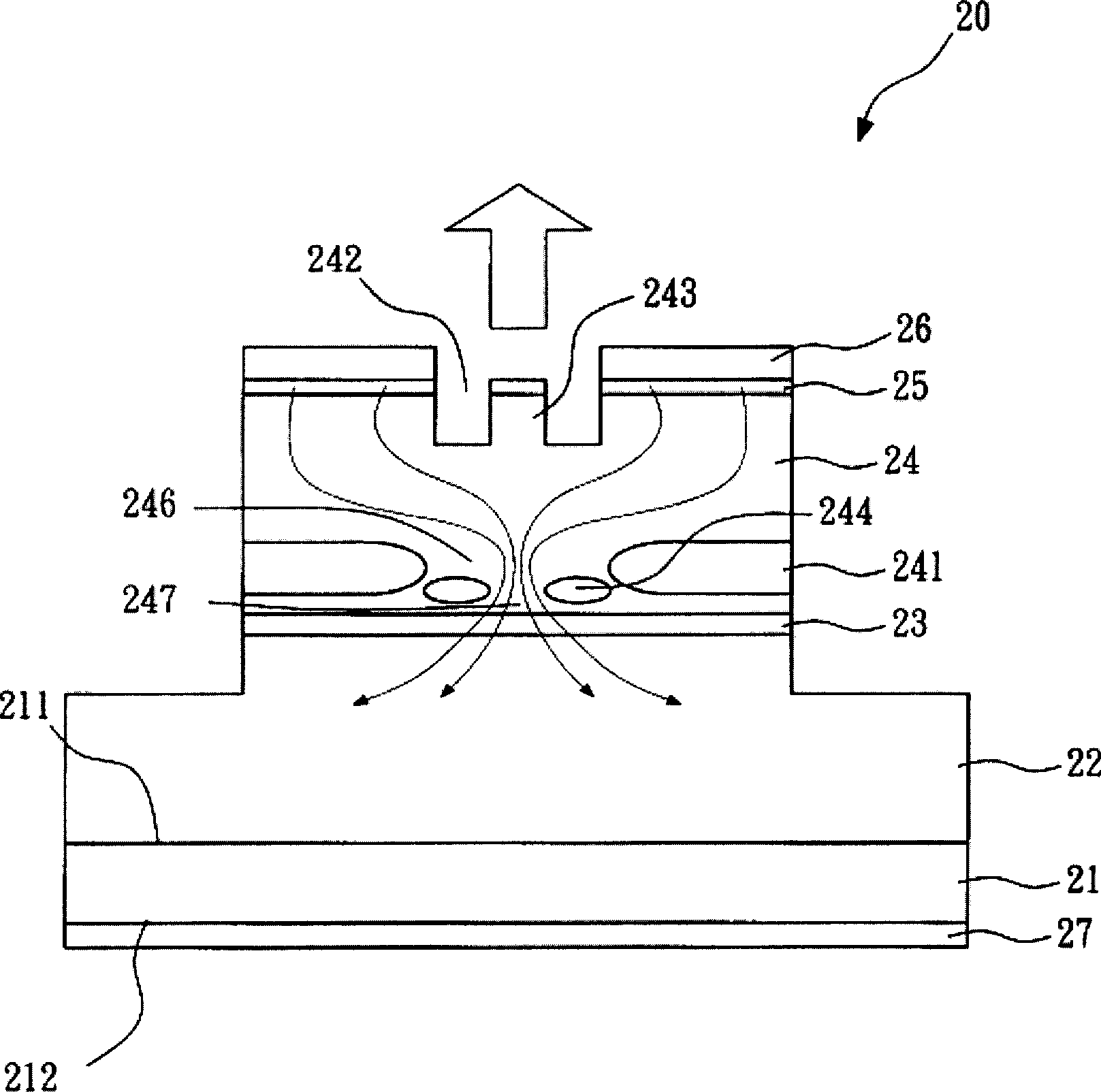

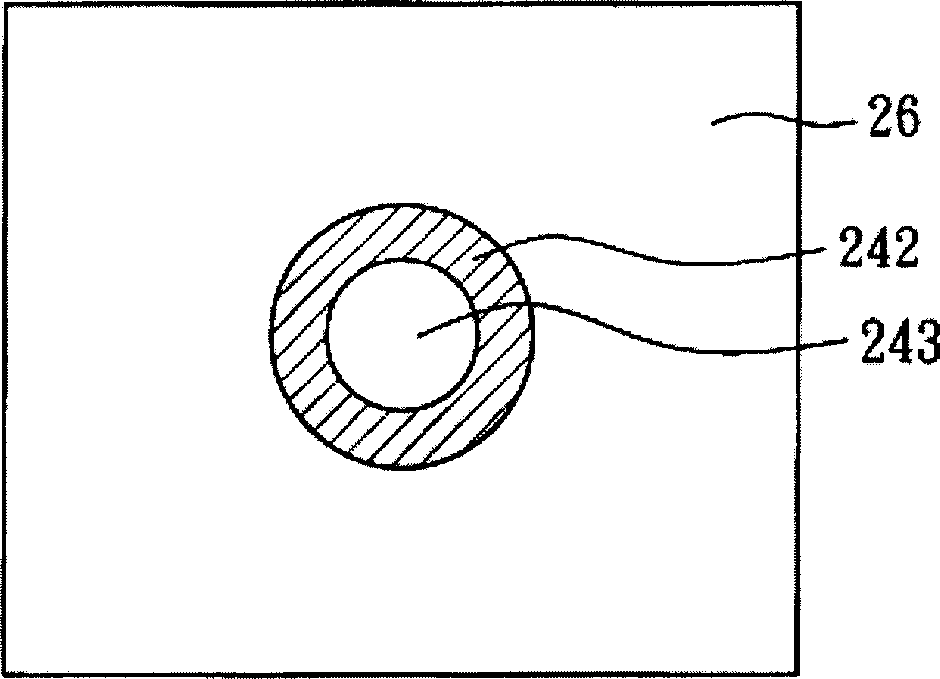

Vertical cavity surface emitting laser and method for fabricating the same

ActiveCN1901299AAchieve widthAchieve thicknessLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserOxygen ions

The invention relates to a vertical cavity surface emitting laser and method for fabricating the same. The vertical cavity surface emitting laser of the invention comprises: a substrate, a first reflector, an active layer, a second reflector, a first electrode layer and a second electrode layer. The second reflector has a first confinement layer with a first aperture and a second confinement layer with a second aperture. The second aperture is smaller than the first aperture. According to the invention, because the second confinement layer is formed by implanting oxygen ion into the second reflector and heating to let the oxygen ion and Al content in the second reflector react to form an oxide layer, the second confinement layer can be used as an optical and electronic confinement layer. Therefore, the width and depth of the second confinement layer can be achieved precisely and easily.

Owner:HIGHER WAY ELECTRONICS +1

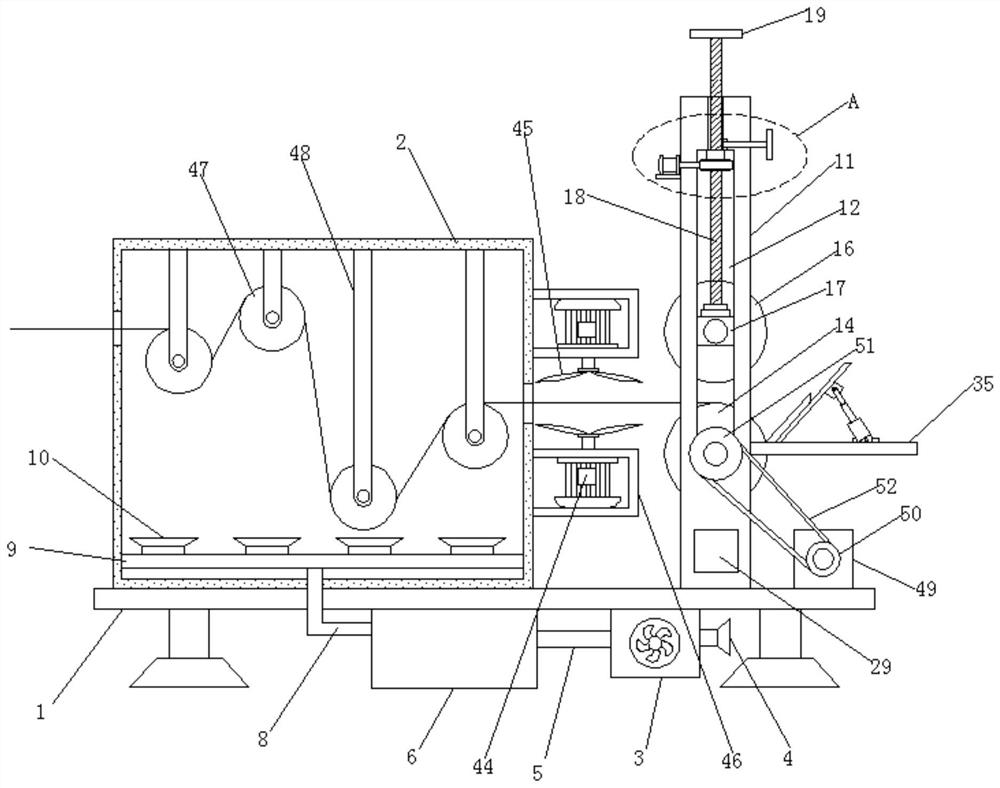

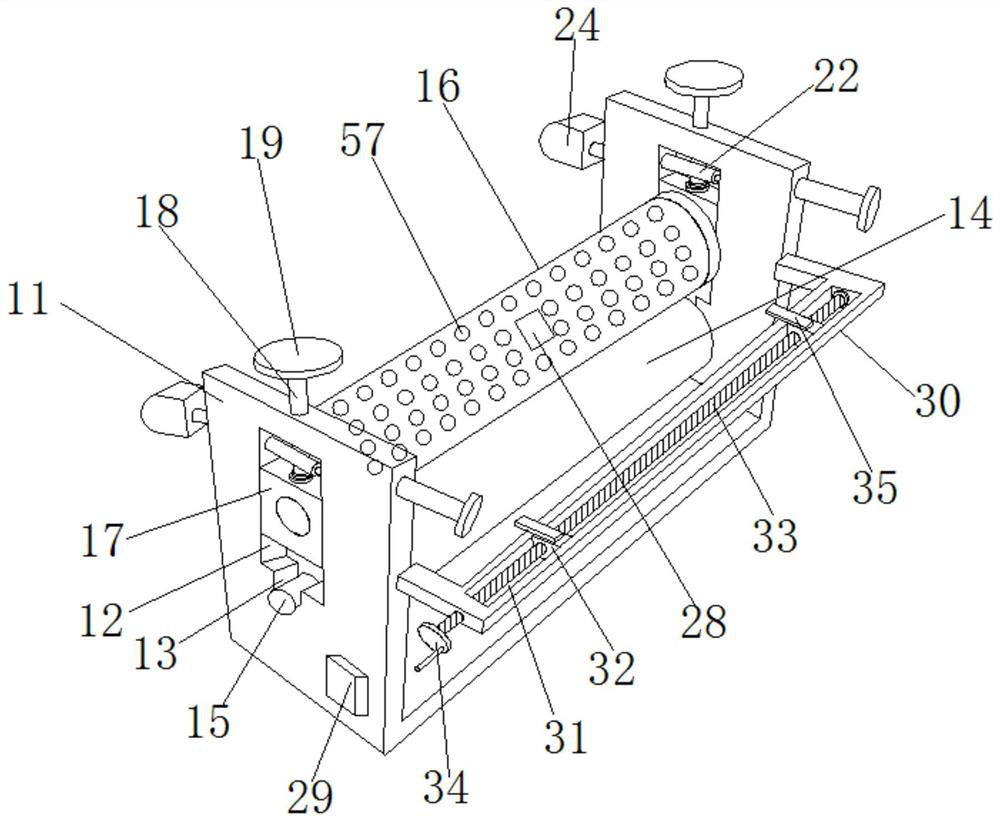

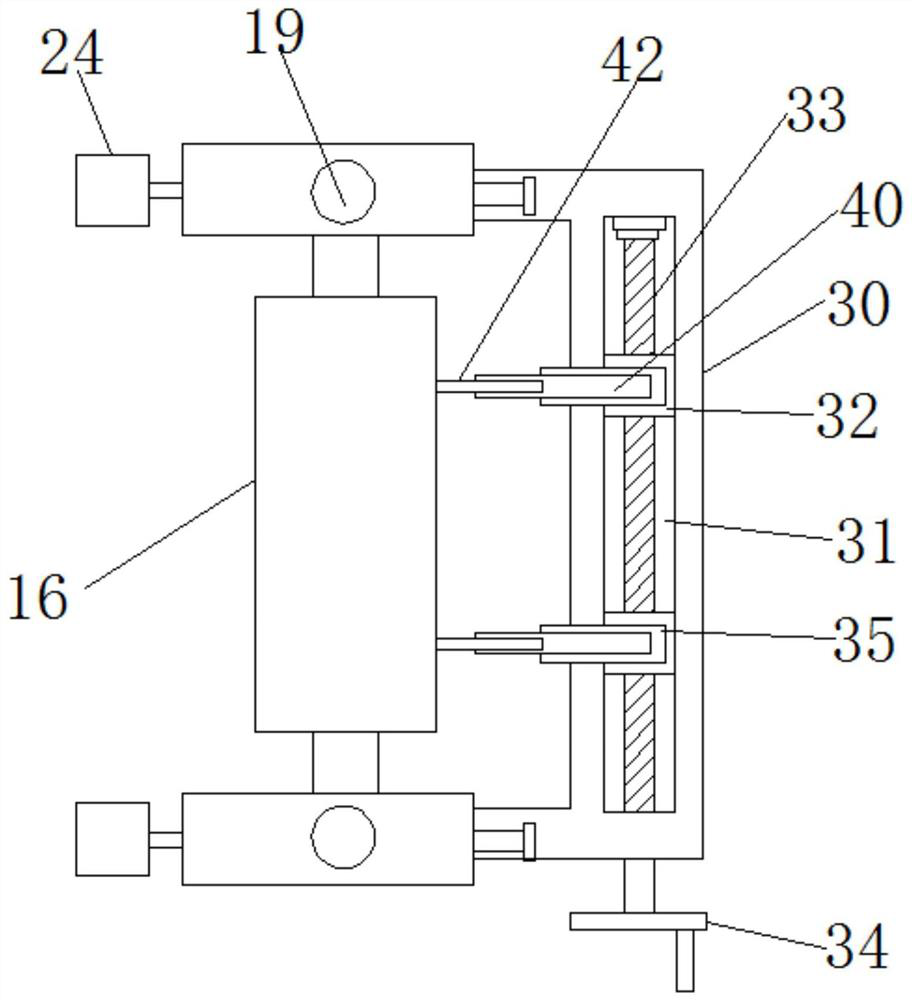

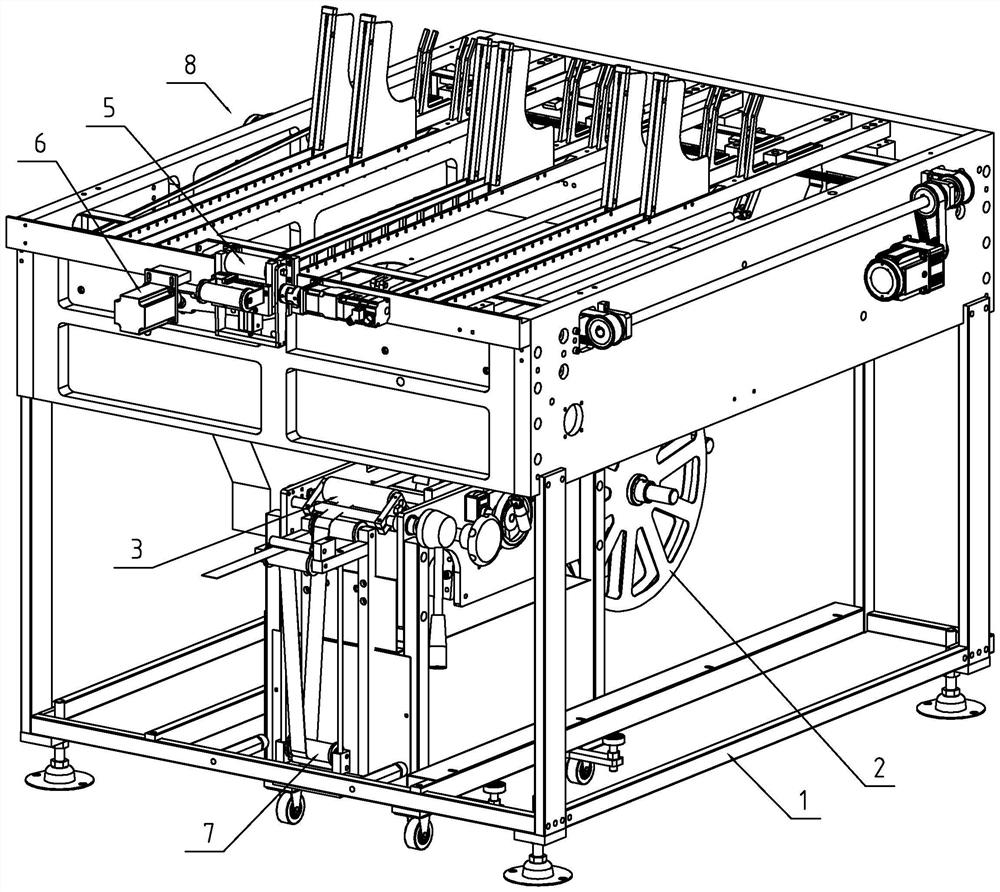

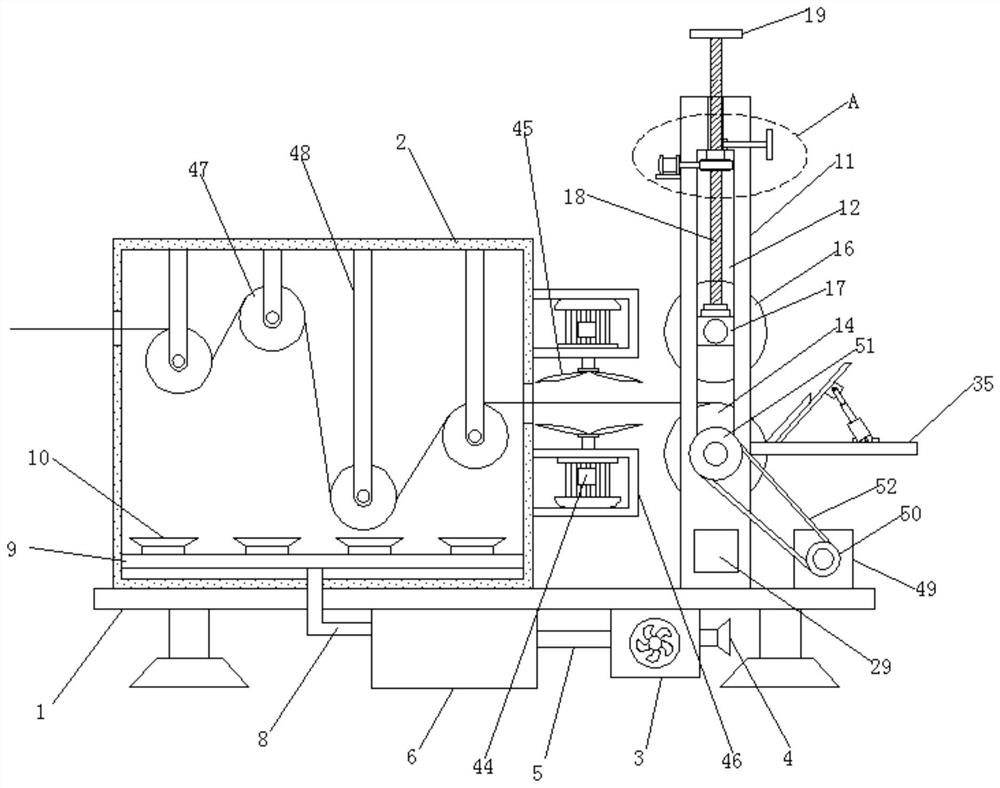

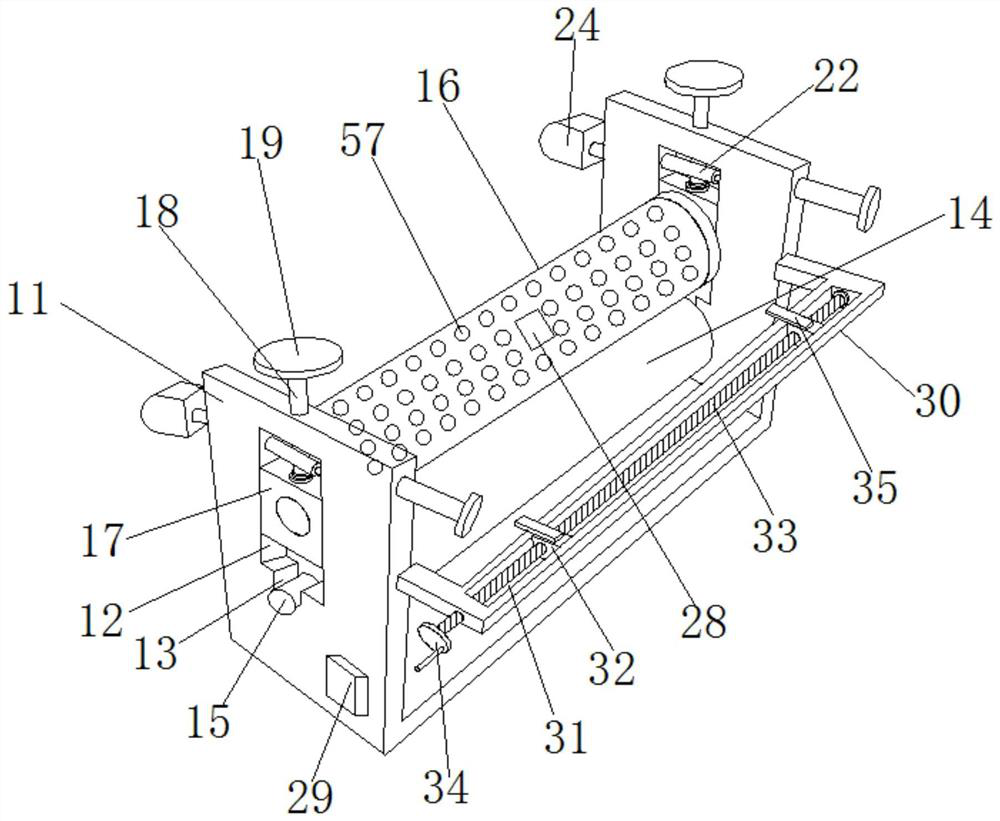

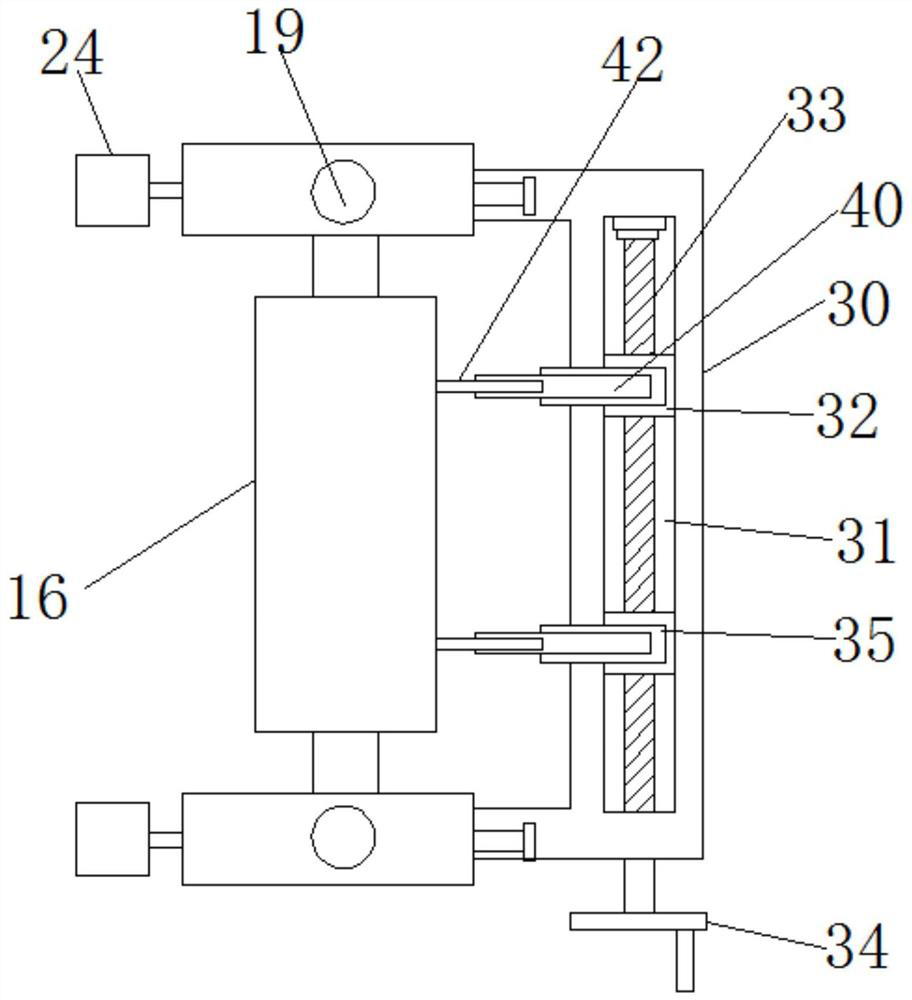

Joint production line for spun-laced nonwoven fabric

ActiveCN111707080AReduce labor intensityAchieve widthDrying gas arrangementsSevering textilesNonwoven fabricManufacturing line

The invention discloses a joint production line for a spun-laced nonwoven fabric. The joint production line comprises a placing base plate; one end of the placing base plate is fixedly provided with abox body; a drying device is arranged inside the box body; the two sides of the box body are each provided with an inlet and an outlet; one side of the box body is provided with an air cooling device; the air cooling device is provided with a winding device at one side of the box body; a pressing device is arranged above the winding device; the drying device comprises a fan; one end of the fan isprovided with an air inlet hood; the end of the fan away from the air inlet hood is provided with a communication pipe; the end of the communication pipe away from the fan communicates with a heatingbox; a plurality of heating nets are arranged inside the heating box; and an L-shaped pipe is arranged at one end of the heating box away from the communication pipe. The joint production line has the beneficial effects of being simple in structure and convenient for adjustment, operation and use, reducing the labor intensity of a worker, and greatly improving the work efficiency.

Owner:射阳县宏瑞纺织机械制造有限公司

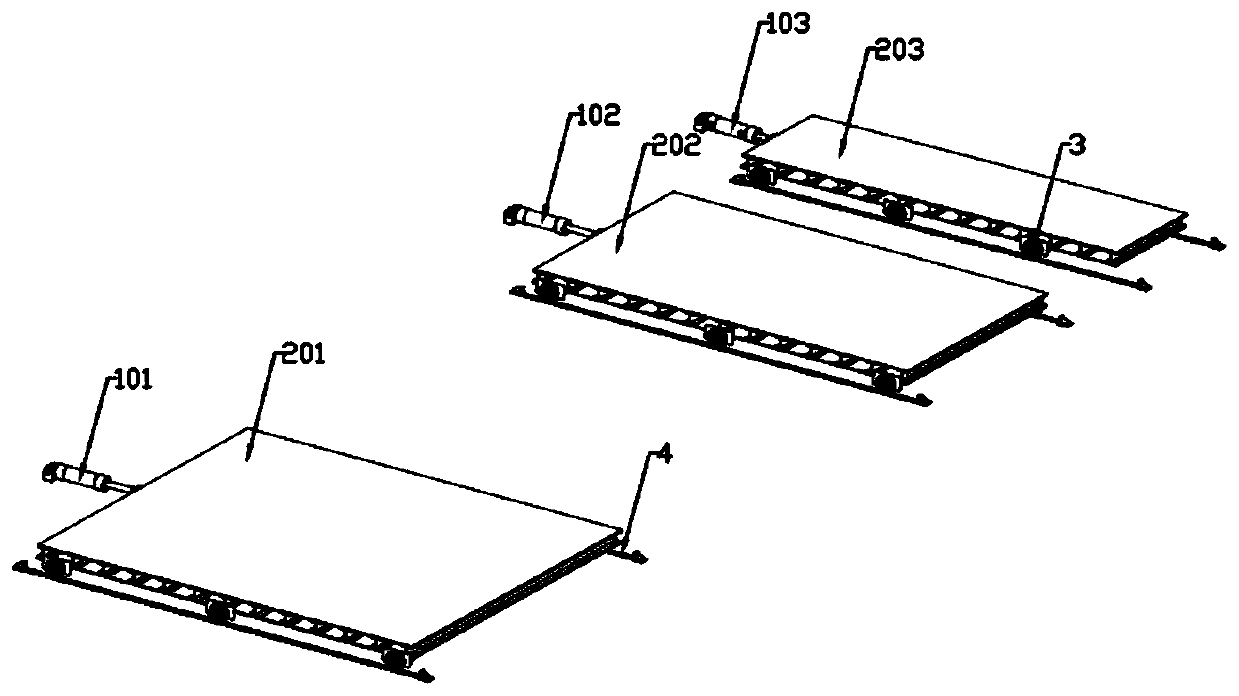

Glass laser cutting equipment

PendingCN111116031ARealize the four-way reformAchieve lengthGlass severing apparatusGlass productionLaser cuttingMechanical engineering

The invention discloses glass laser cutting equipment, and relates to the technical field of glass processing; the glass laser cutting equipment is additionally provided with linear module conveying on the basis of original belt conveying, the linear module conveying precision is high, and the hole site processing precision is effectively improved. And meanwhile, the glass laser cutting equipmentis provided with a transverse alignment measuring assembly and a longitudinal alignment measuring assembly, so that four-direction alignment and length and width measurement of glass are realized, theglass positioning accuracy is improved, and the hole site machining precision is further improved.

Owner:ZHEJIANG HUA GONG GLORY INTELLIGENT EQUIP TECH CO LTD

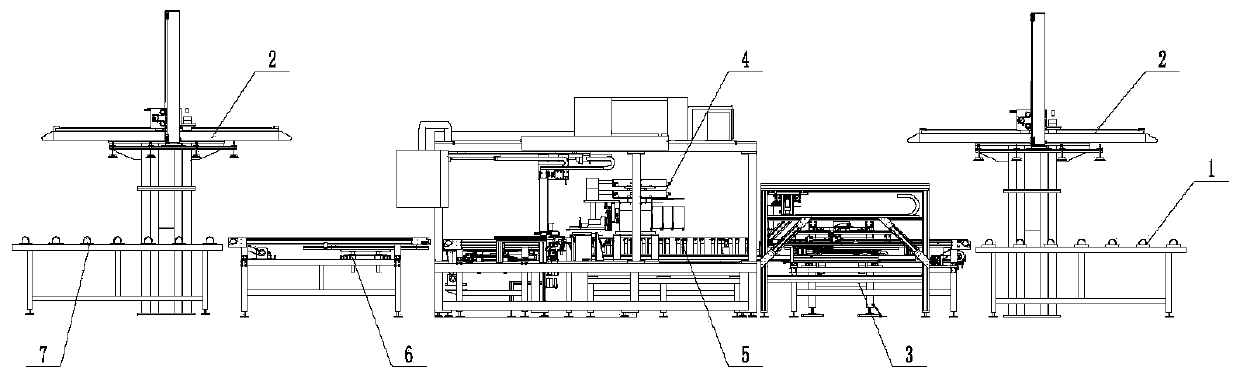

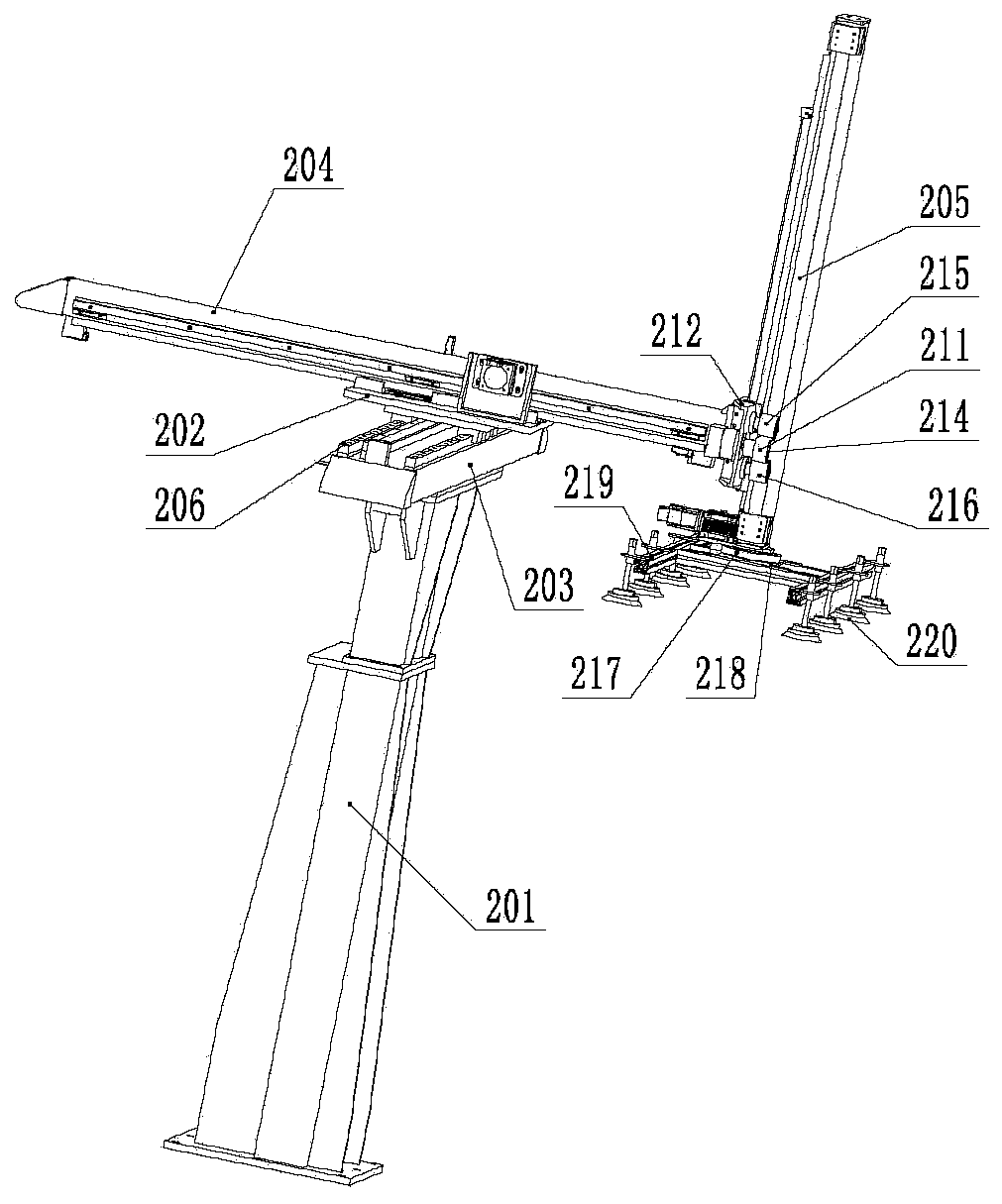

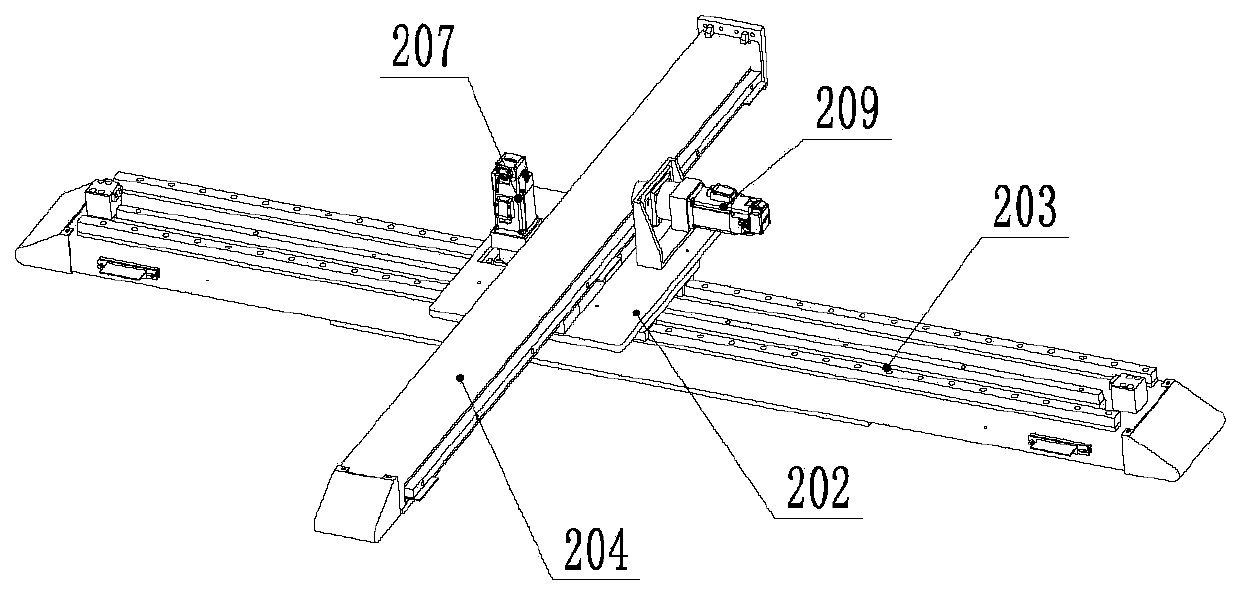

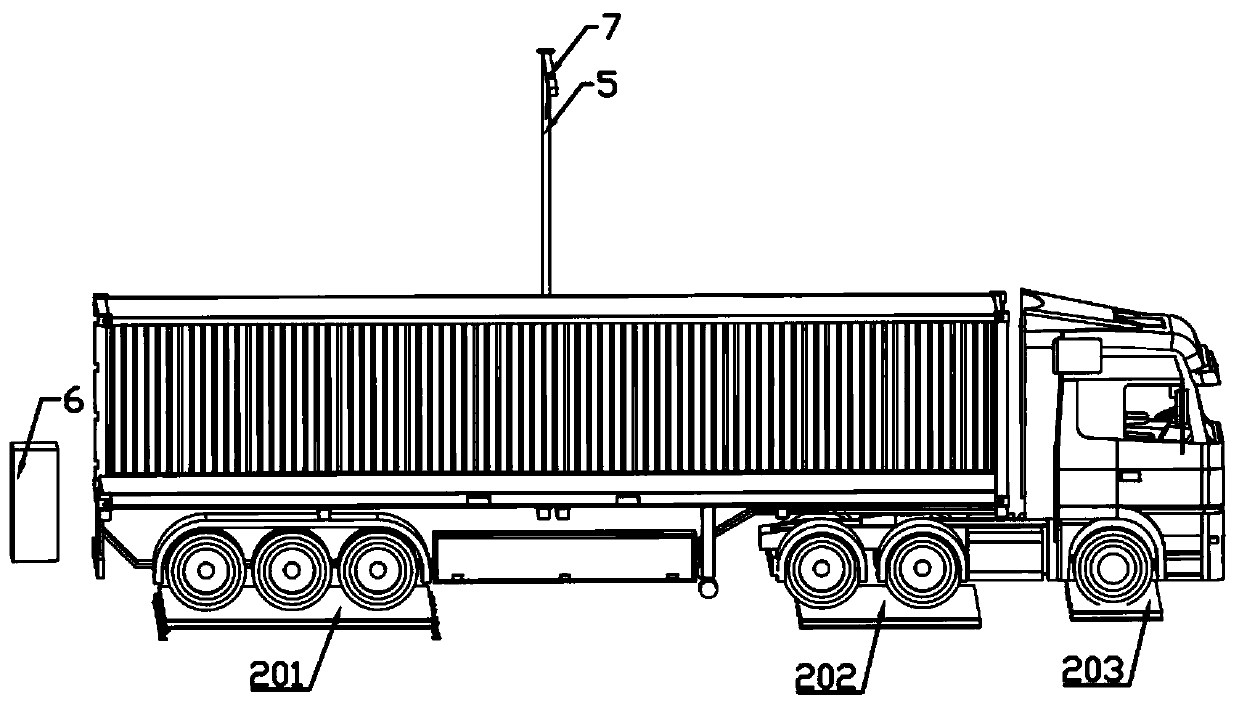

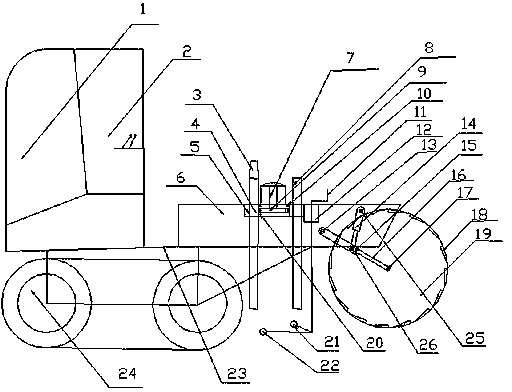

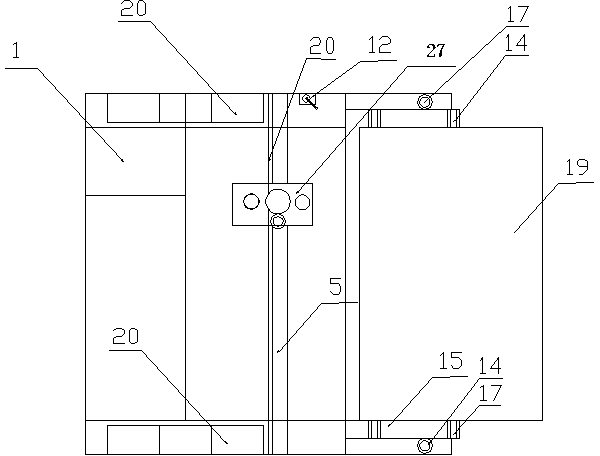

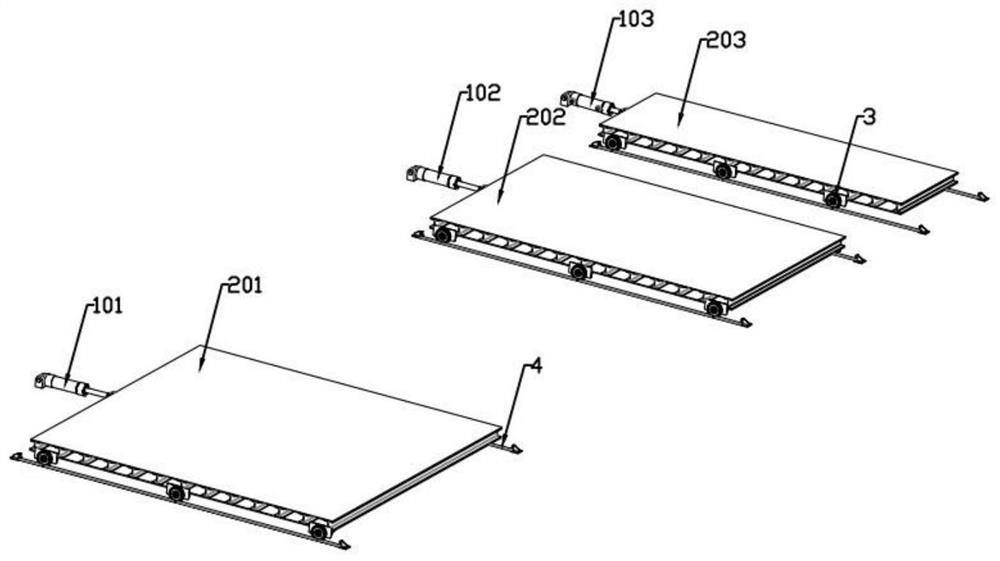

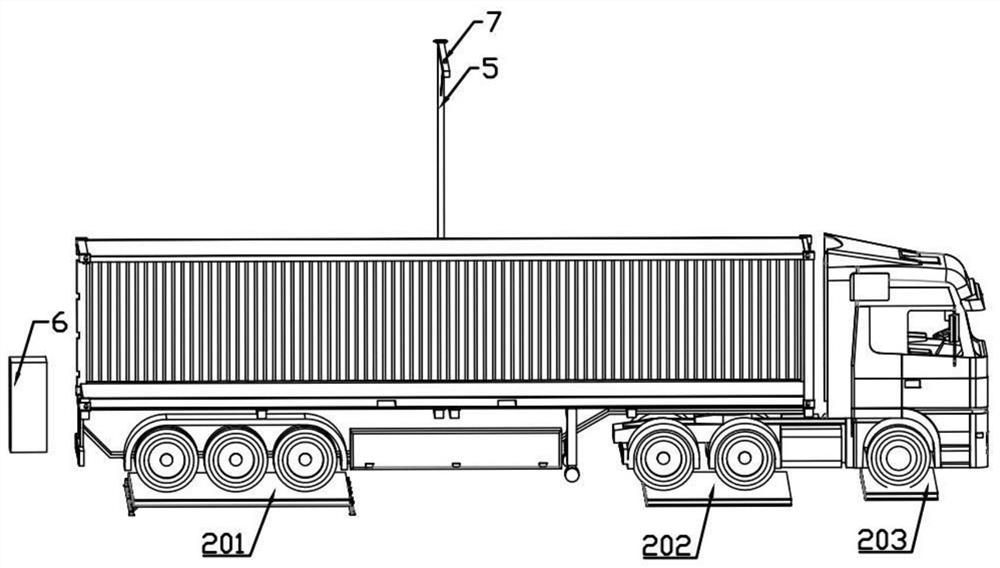

Truck loading pose adjusting device and adjusting method thereof

The invention relates to a truck loading pose adjusting device and an adjusting method thereof, and belongs to the technical field of truck pose adjustment. The adjusting device comprises movable platforms, steel wheels and a hydraulic cylinder, wherein the steel wheels are positioned below the two sides of the movable platforms, and the hydraulic cylinder is used for driving the movable platforms; three sets of the movable platforms are arranged, the three sets of movable platforms are located in three pits of the ground respectively, and the distances between the three sets of movable platforms correspond to the intervals between three sets of wheels of the truck respectively; guide rails are arranged below the steel wheels in the pits, the steel wheels slides along the guide rails to achieve the movement of the movable platforms in the width direction, so that the problems that an existing automatic loading system is difficult to accurately place the truck on the loading position and truck position and angle adjustment are encountered during loading are solved, the automation degree of the automatic loading system is improved, the loading efficiency is improved, and the labor cost is saved.

Owner:SHANDONG UNIV OF SCI & TECH

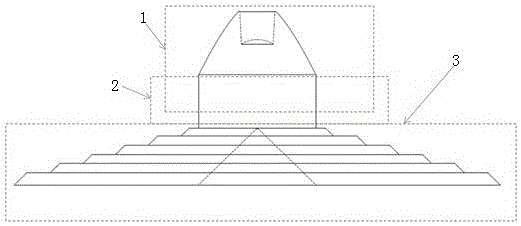

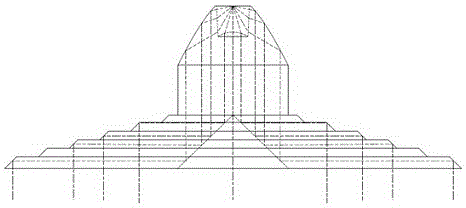

3D (3-dimensional) molding machine

InactiveCN103821070AAchieve widthFulfillment requirementsRoads maintainenceMolding machineRoad surface

The invention discloses a 3D (3-dimensional) molding machine, and belongs to the technical field of road construction machinery. The 3D molding machine comprises a crawler-type vehicle, a pouring device and a pavement molding roller, and is characterized in that a pouring cylinder and a high-frequency vibration instrument are controlled by a servomotor to move back and forth along a transversal groove through a gear and a rack, and the pouring cylinder is used for pouring in a thickening manner layer upon layer until a required thickness is detected by a road thickness control sensor; pouring cylinder automatically moves forwards to pour the next road according to the instruction of a road direction indicator, and when a section of the road is fully poured, the pavement molding roller starts to work, so as to enable the pavement to be molded through one step. According to the invention, the power required by the 3D molding machine is only one tenth of the combined-type machine for the large-scale road, or even less; the 3D molding machine has the advantages that the structure is simple and reasonable, the machine is economical and practical, the cost is low, the quality is good, and the effect is excellent, so that the 3D molding machine is suitable for paving small-scale roads.

Owner:扬州亚科科技咨询有限公司

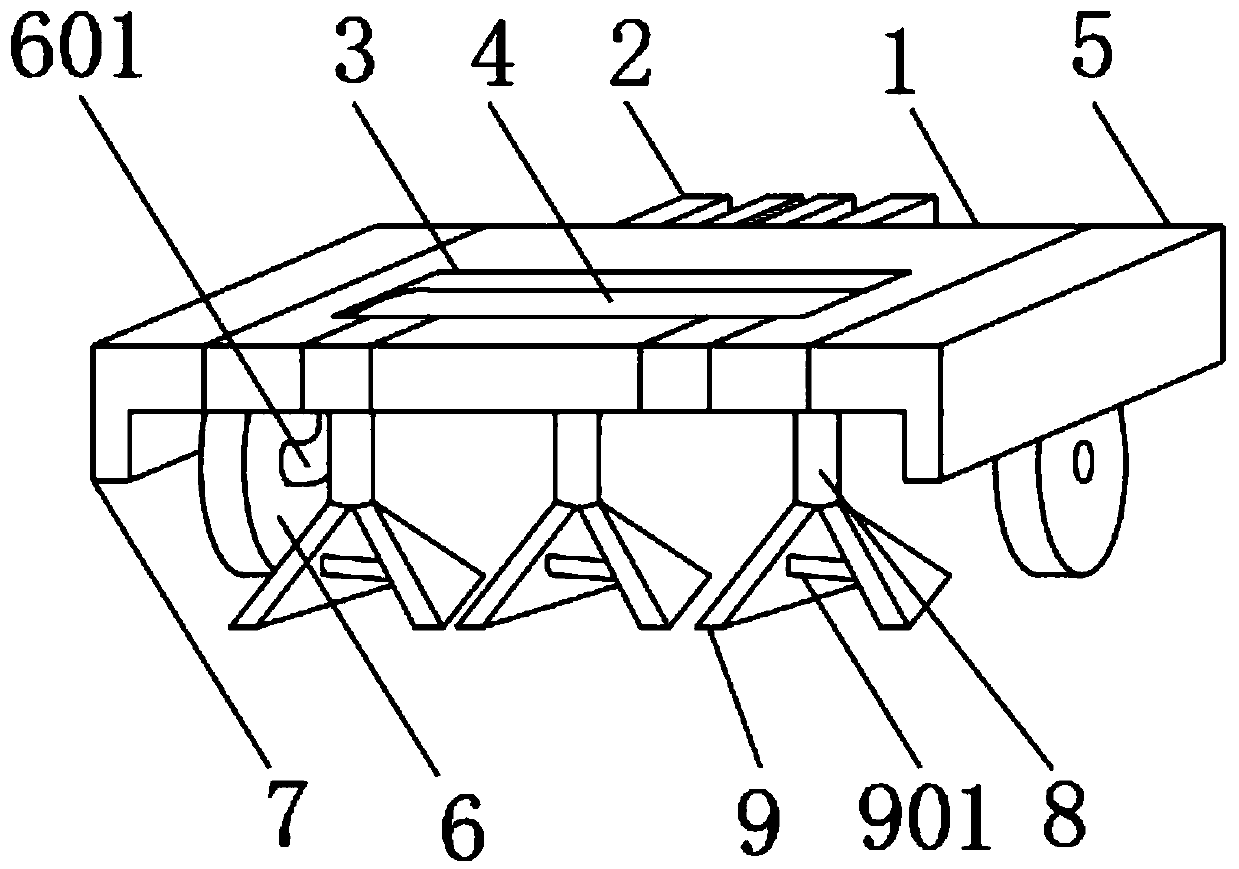

Farmland ridging facility in agriculture and forestry

InactiveCN109526271AAchieve widthEasy to operateSoil-working equipmentsAgricultural engineeringAgriculture

The invention discloses a farmland ridging facility in agriculture and forestry. The farmland ridging facility comprises a body. A first fixed plate is fixed on the outer surface of the rear end of the body. The outer surface of the upper end of the body is provided with a groove. A press plate is movably arranged in the groove. A moving plate is movably arranged on the outer surface of one side of the body. A roller is movably arranged on the lower end of the body. A baffle plate is fixedly arranged on the outer surface of the lower end of the moving plate. A support rod is movably arranged on the outer surface of the lower end of the body. A ridging plate is movably arranged on the outer surface of the lower end of the support rod. By setting a series of structures, the provided facilitycan be well adjusted during the using process, a user can adjust the ridging plate according to the required distance between two ridges, the body can be extended, the user can adjust the facility according to the ridge width, and the facility is suitable for all kinds of soil and is convenient to use.

Owner:GANSU DESERT CONTROL RES INST

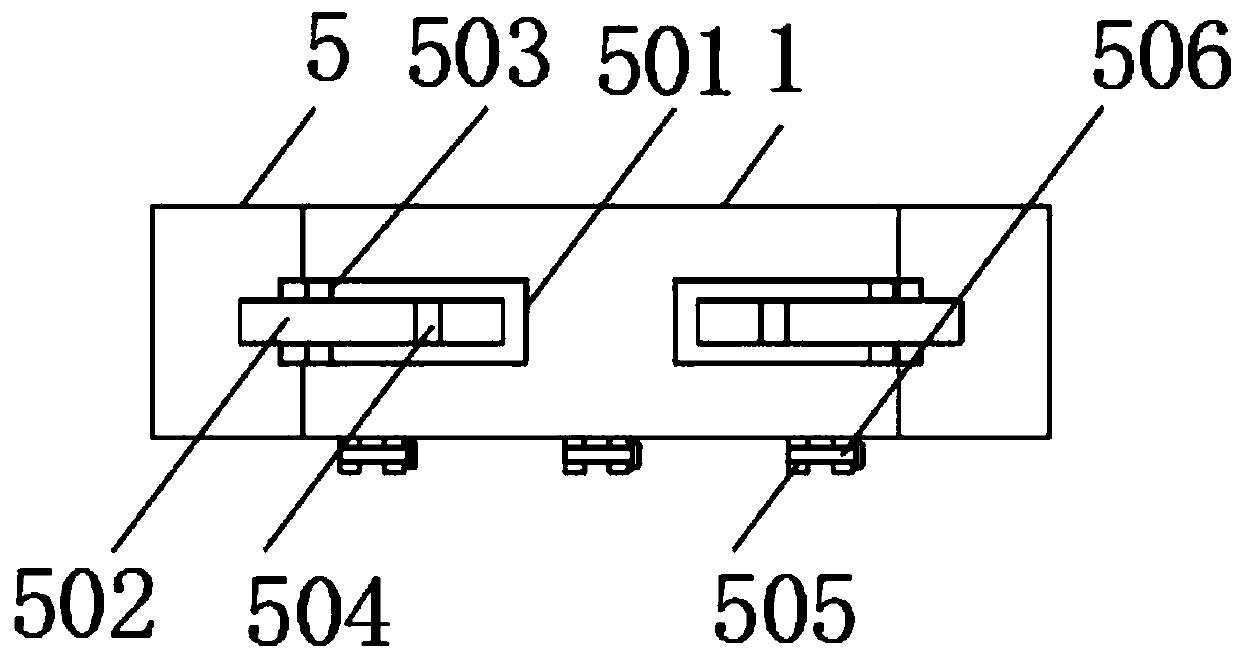

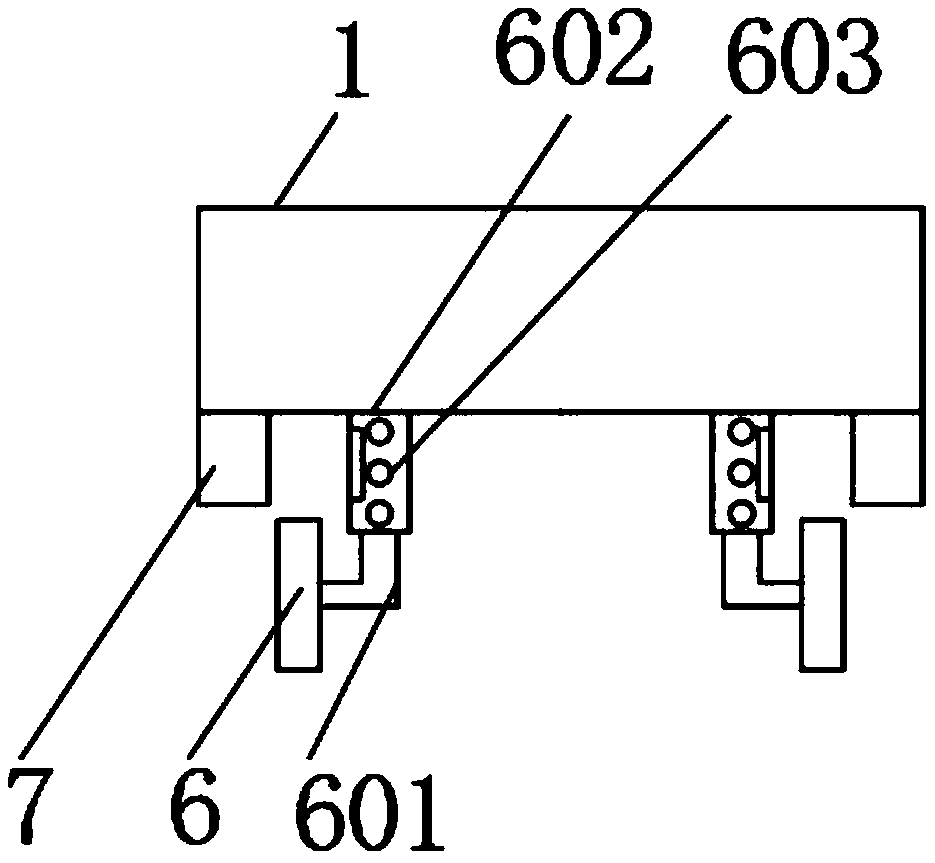

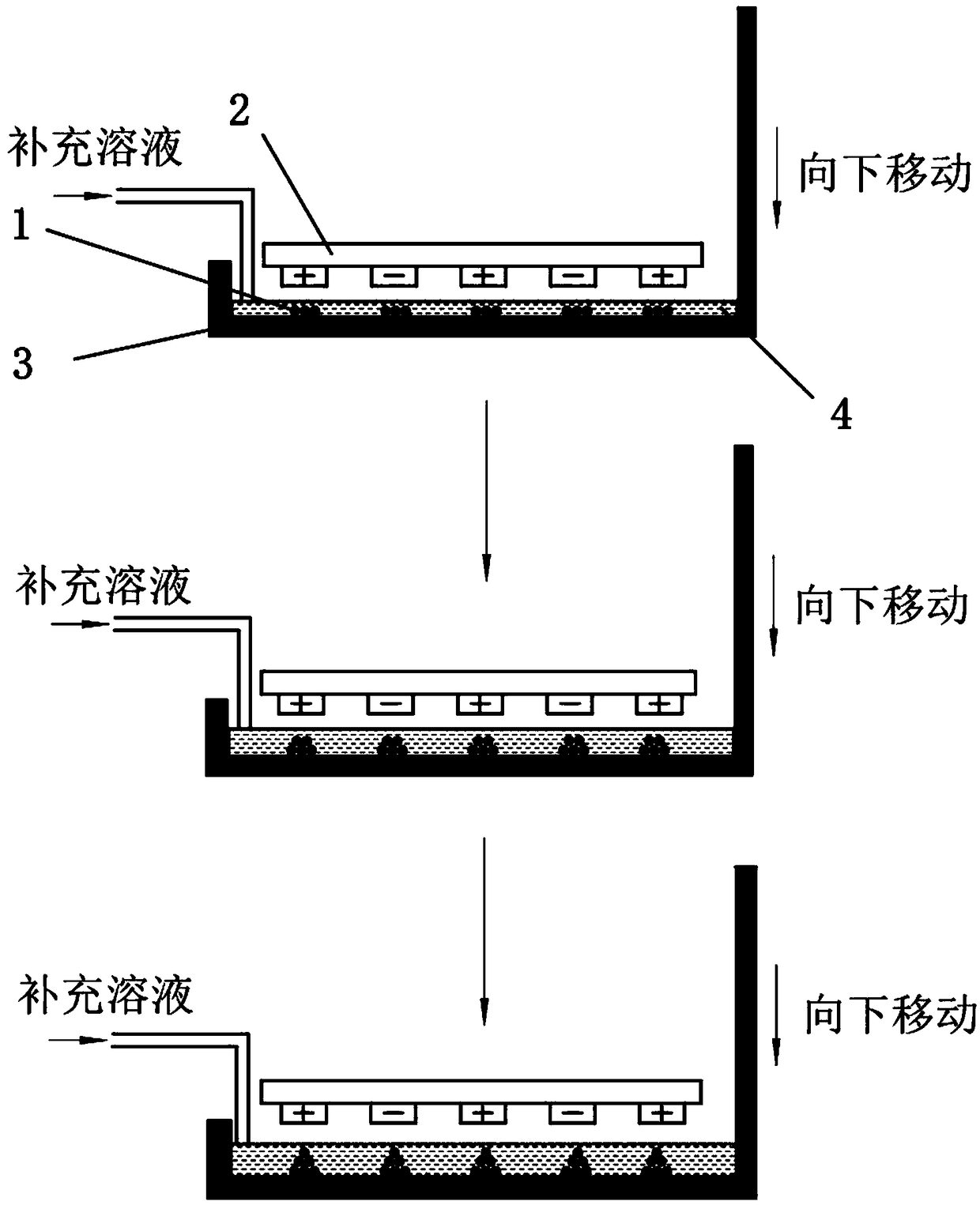

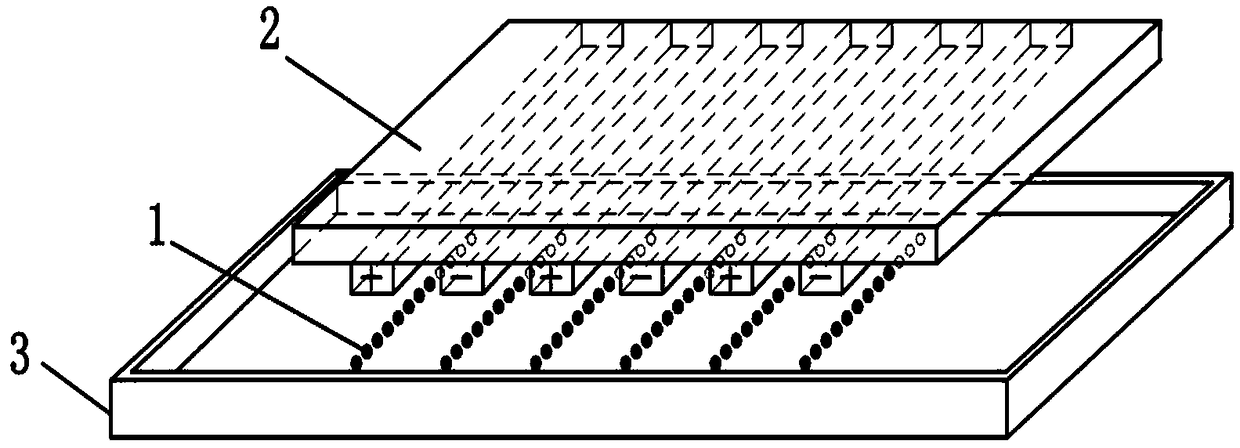

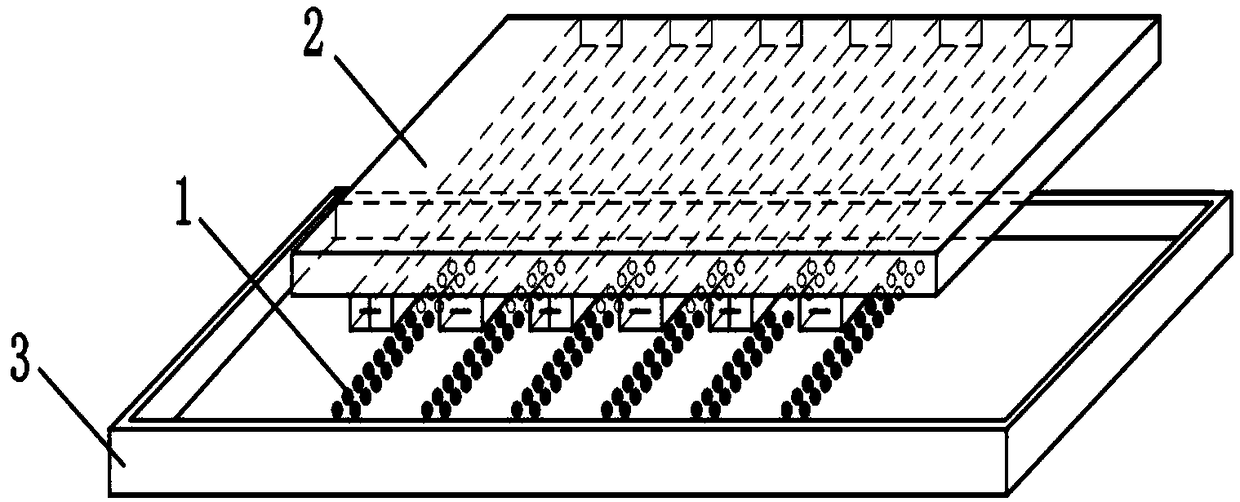

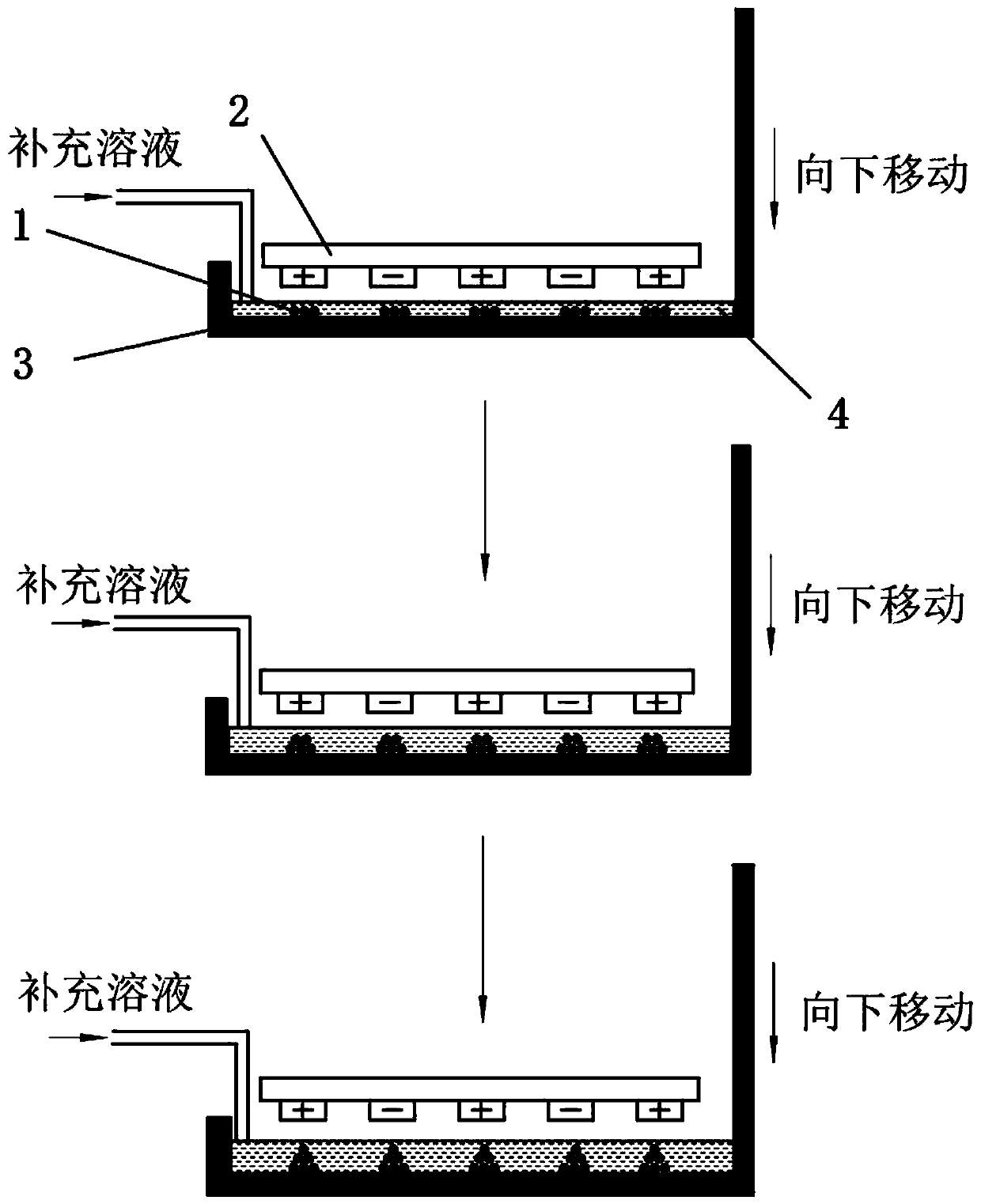

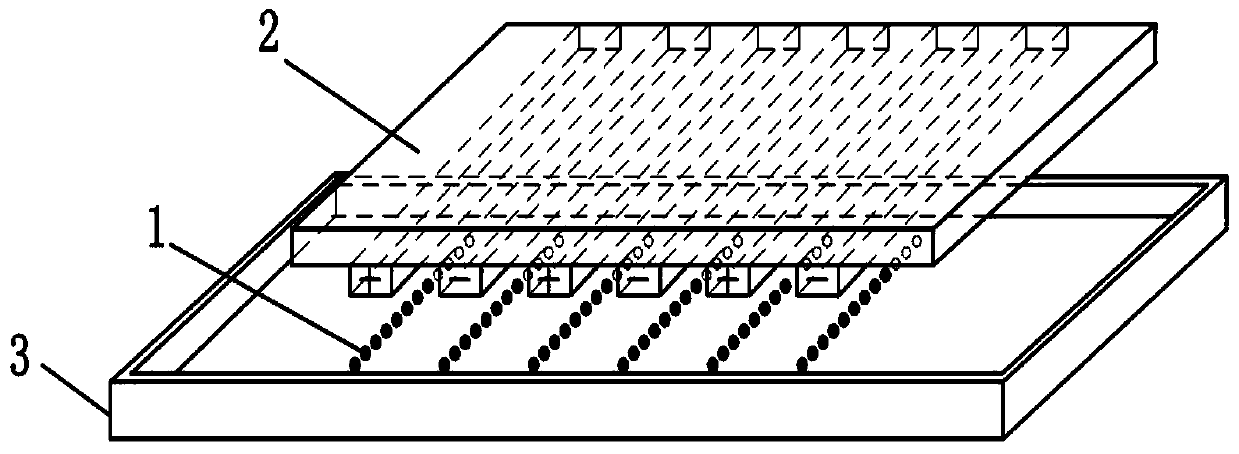

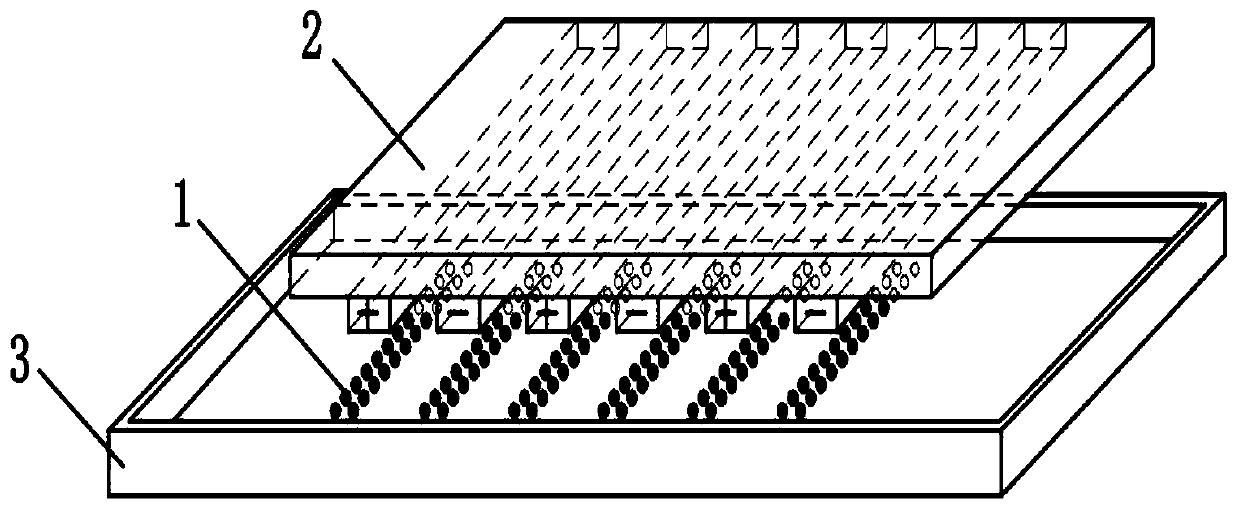

Method for manufacturing composite material based on nano-particle three-dimensional micro-nano structured arrangement

ActiveCN109467046ARealize directional and localized controlRealize three-dimensional patterned arrangementSpecific nanostructure formationNanostructure manipulationMicro nanoNanoparticle

The invention relates to a method for manufacturing a composite material based on nano-particle three-dimensional micro-nano structured arrangement, which comprises the following steps of: placing micro-nano particles in mother liquor to obtain a solution containing micro particles; placing part of the solution in a container for leveling, applying a first structured field to the solution in a container, and controlling the particles in the solution to achieve controllable patterning arrangement of the particles in the solution; solidifying and molding the solution in the container, moving thecontainer downwards, supplementing the solution containing the micro particles in the container, changing structural field parameters to achieve the longitudinal controllable arrangement of the particles in the solution, and adopting different structural fields to achieve different patterning arrangements of the particles in the solution containing the micro particles; changing a first structuralfield into a second structural field so that the particles are arranged into corresponding shapes; repeating until the composite material with three-dimensional micro-nano structured arrangement of functional nanoparticles is obtained; the method has the advantages of directional localized adjustment, high efficiency, capability of achieving the forming of any three-dimensional shape structure and the like.

Owner:XI AN JIAOTONG UNIV

Vertical environment-friendly novel copper foil production device

InactiveCN106521565AIncrease costImprove efficiencyElectroforming processesEnvironmental resistanceMetallurgy

The invention discloses a vertical environment-friendly novel copper foil production device. The vertical environment-friendly novel copper foil production device comprises a synchronous power source, a copper foil work groove and a support arranged above the copper foil work groove. A first cathode wheel communicating with the negative electrode of the synchronous power source is arranged in the copper foil work groove. First anode plates communicating with the positive electrode of the synchronous power source are arranged on the two sides of the first cathode wheel. Two guide wheels are arranged on the top of the support. The guide wheels and the first cathode wheel are connected through a strip-shaped copper foil generation carrier. The copper foil generation carrier enters the copper foil work groove in a vertical manner, and a collecting roller used for collecting copper foil generated on the copper foil generation carrier is arranged on one side of the copper foil work groove. The synchronous switch power source is connected with a cathode and an anode for electrification, copper sulfate electroplating liquid with a certain requirement is prepared, the copper foil is manufactured on a cathode carrier, and the beneficial effects that cost and energy consumption are low, and efficiency is high are achieved.

Owner:昆山元天电子有限公司

A method and device for realizing a bidirectional optical diode

ActiveCN104882783BChange positionChange widthLaser output parameters controlRefractive indexCoupling constant

The invention provides a method and device for realizing a bidirectional optical diode. The invention scheme is as follows: two oppositely incident coupling fields with a certain frequency detuning act on the hot alkali metal atom vapor chamber, so that the atomic medium periodically modulates the refractive index of the probe light, so that the two-way incident probe The transmission characteristics of light are effectively manipulated, realizing the function of a bidirectional optical diode with a certain frequency interval and frequency width. Doppler effect. Simultaneously introducing a pair of coherent pump fields can effectively improve the bidirectional transmission efficiency of the optical diode without affecting its isolation ratio. The device involved in the invention is easy to miniaturize and integrate, and forms a practical optical quantum device, which is widely used in multi-channel quantum state storage, quantum information storage such as tunable all-optical control optical switches, optical mirrors, and quantum relay networks. field.

Owner:北京瓦科光电科技有限公司

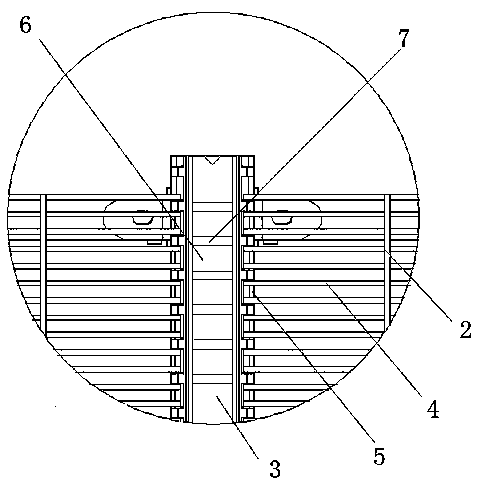

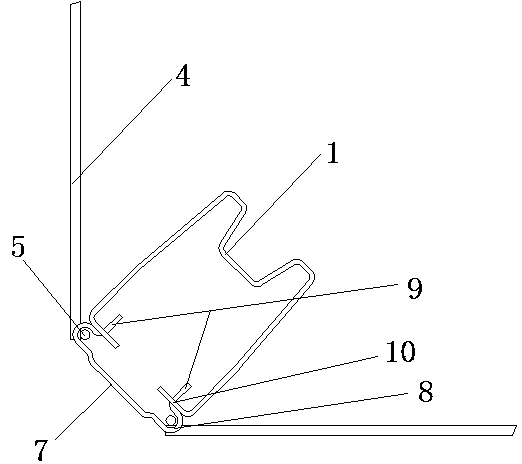

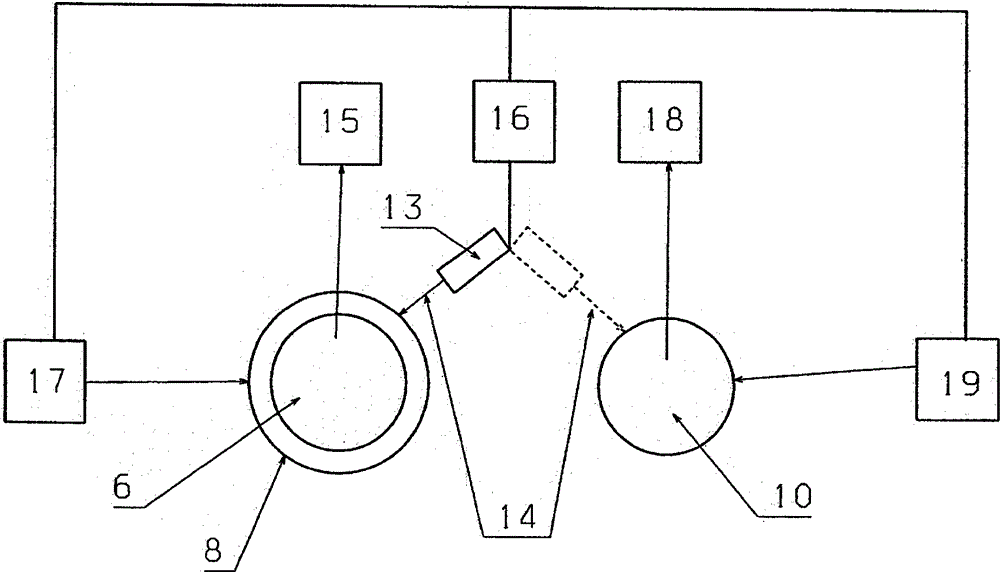

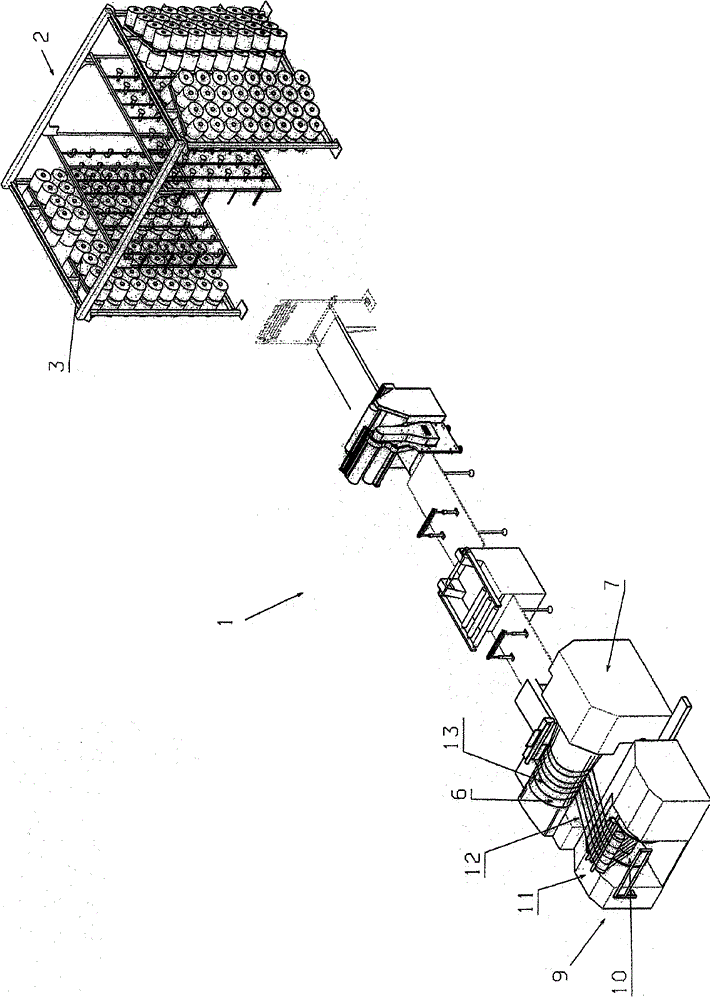

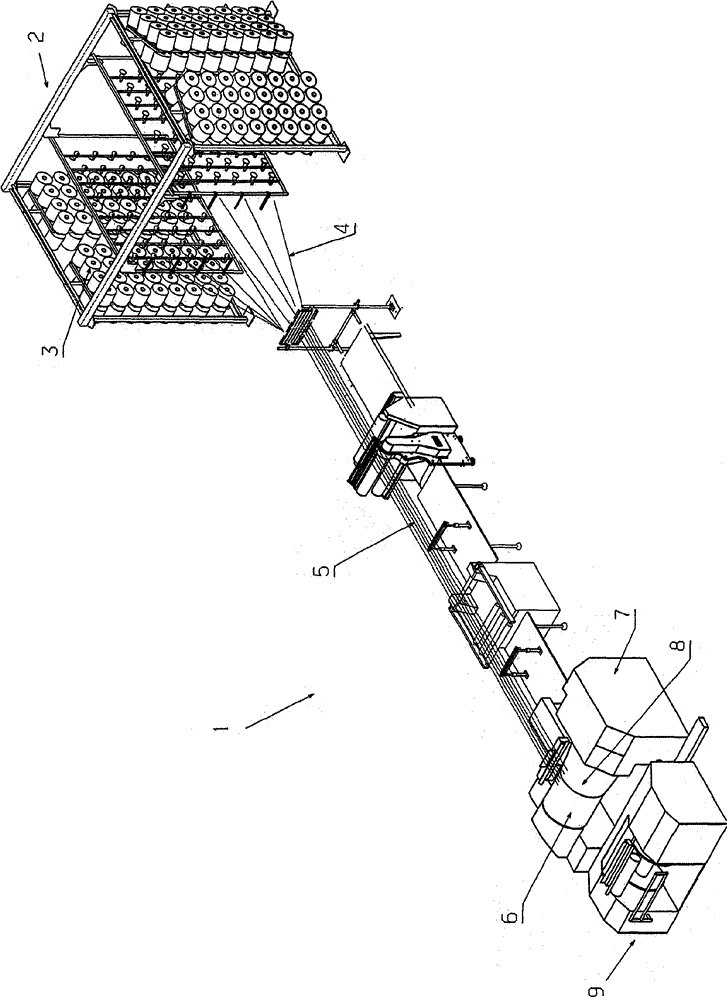

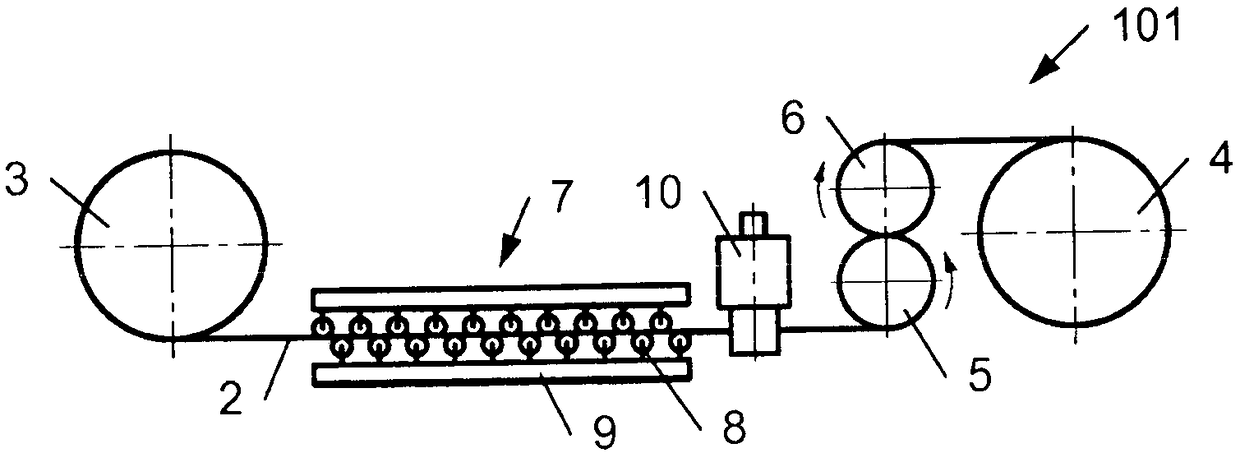

Method and device used for manufacturing at least two section beams in one set

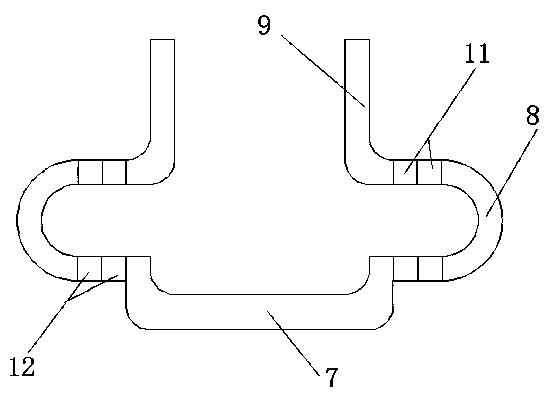

The utility model relates to a device used for manufacturing at least two section beams, used for the weaving process, in one set. On the device, yarn from a yarn source is wound around a section beam core. Users hope to manufacture the section beams in one set at an appropriate cost. Thus, the yarn is set to be wound around a beaming roller (6) of a beaming device (7) before being wound around the section beam core (10), and the yarn is then beamed on the section beam core (10) again.

Owner:KARL MAYER TEXTILMASCHFAB GMBH

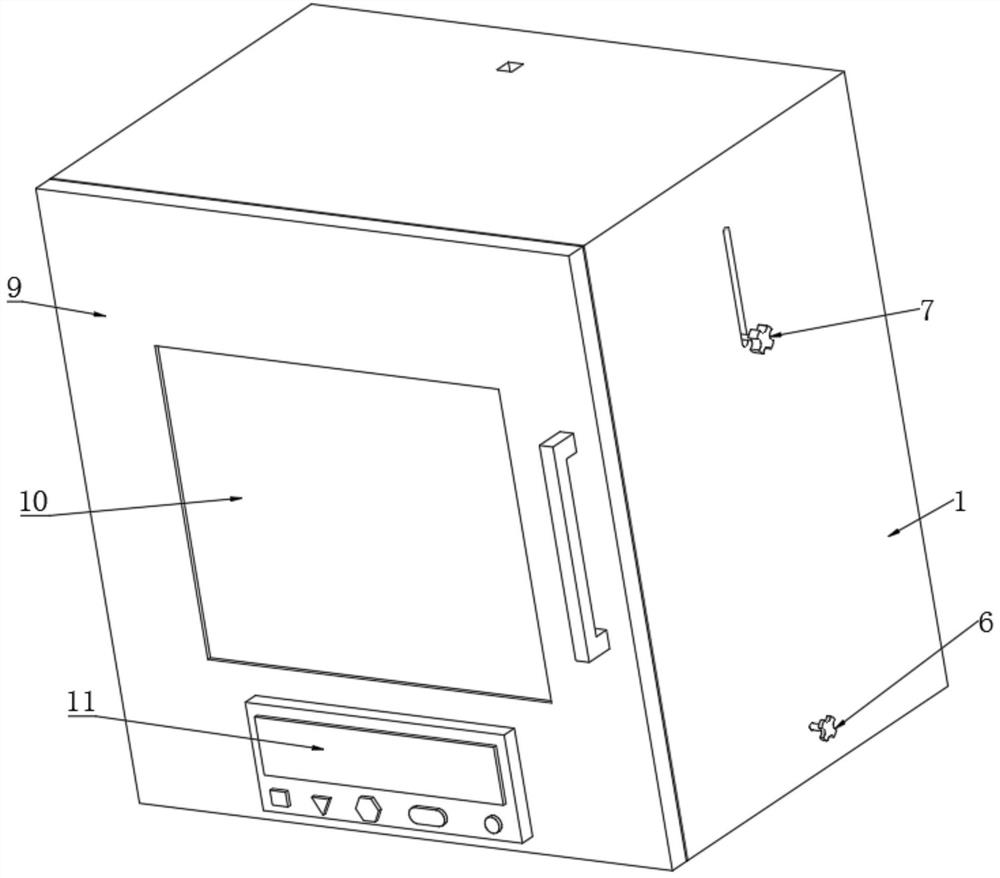

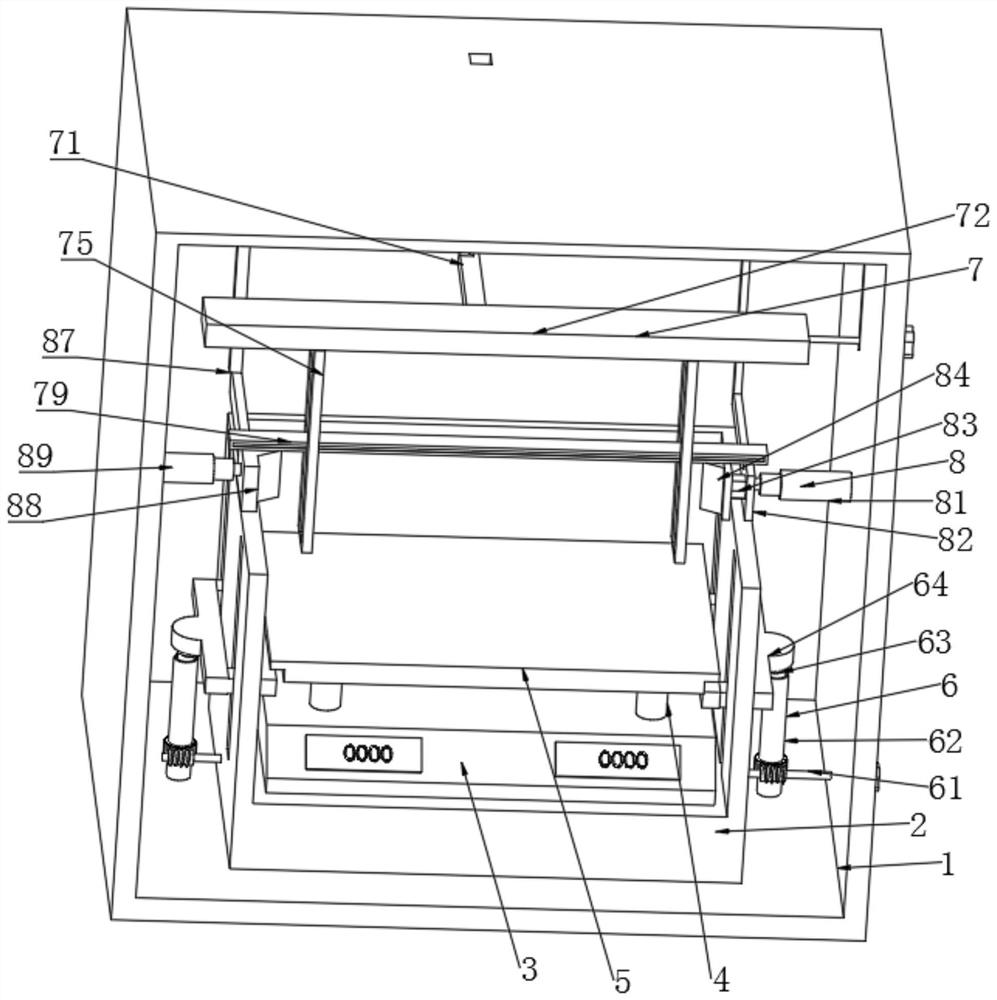

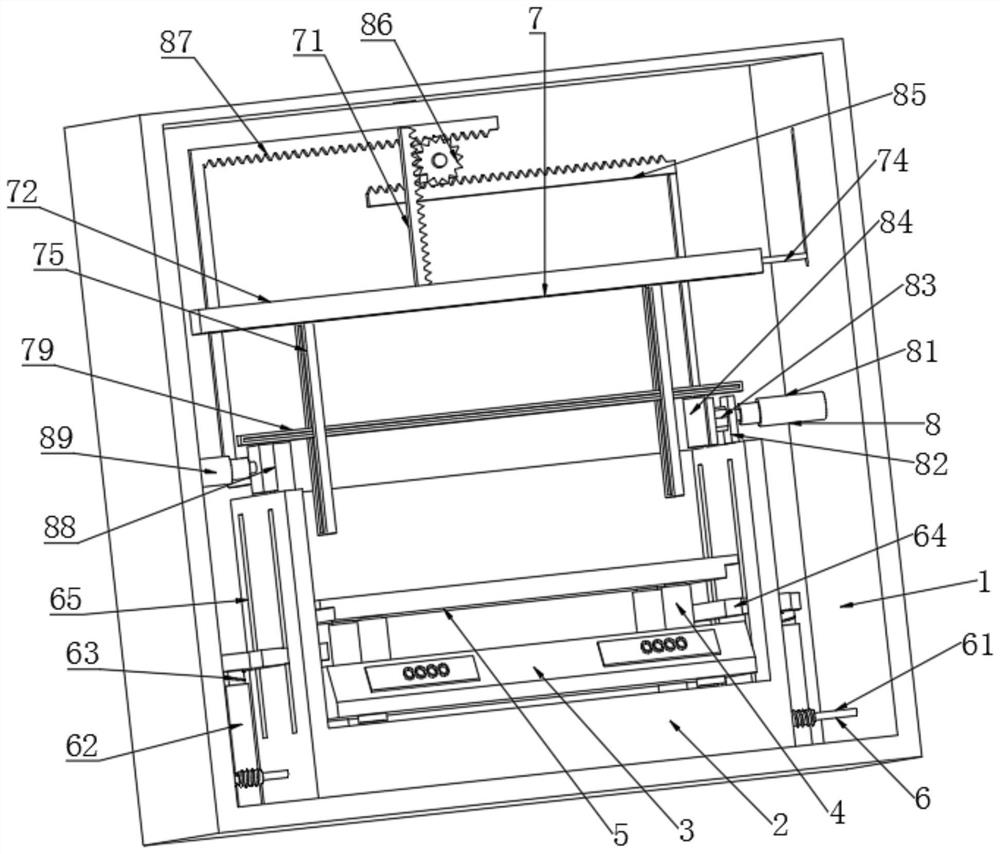

Multifunctional metal material detection device

InactiveCN114441308AAchieve heightAchieve widthMaterial strength using tensile/compressive forcesMechanical thickness measurementsMetallic materialsEngineering

A multifunctional metal material detection device disclosed by the present invention comprises a detection box, a baffle plate is fixedly connected to the bottom of an inner cavity of the detection box, an electronic scale is fixedly connected to the bottom of an inner cavity of the baffle plate, a sleeve is fixedly connected to the upper end face of the electronic scale, and a tray is slidably connected to an inner cavity of the sleeve. Lifting devices are installed at the positions, on the two sides of the baffle, of an inner cavity of the detection box, a measuring device is installed at the position, above the baffle, of the inner cavity of the detection box, extrusion devices are installed at the two sides of the wall of the inner cavity of the detection box, a box door is rotationally connected to the front end face of the detection box through hinges, and an observation window is formed in the middle of the box door; and a control panel is fixedly connected to one side of the box door and located below the observation window. The multifunctional metal material detection device solves the problem that a traditional metal material detection device is inconvenient to detect the weight and hardness of a material at the same time.

Owner:苏州捭源金属材料科技有限公司

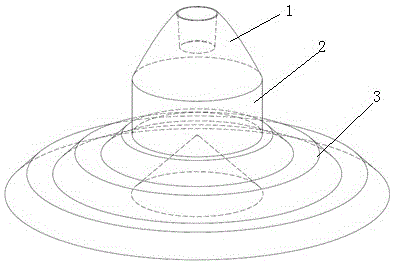

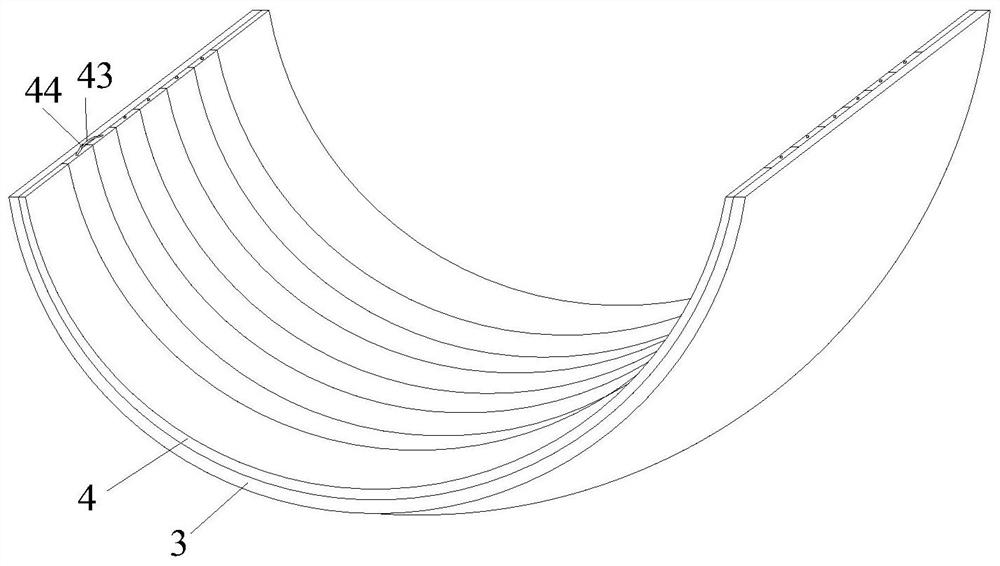

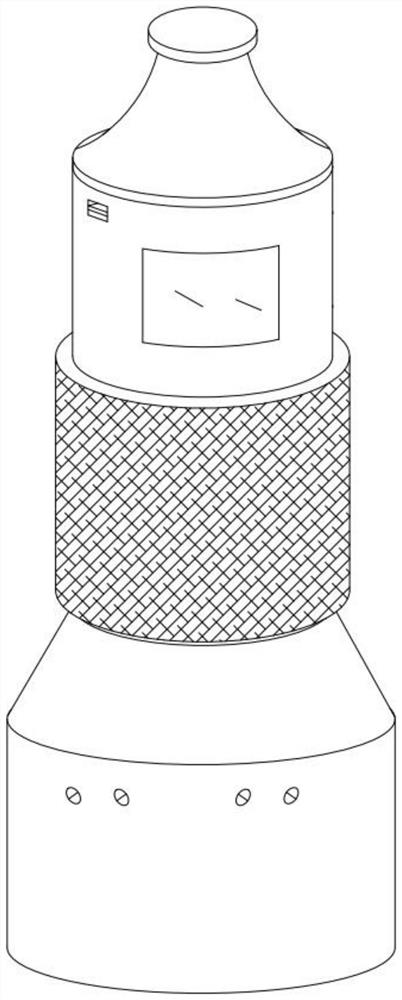

LED optical lens

InactiveCN105042510AEfficient use ofUniform brightnessPoint-like light sourceOptical signallingOptoelectronicsConcentric ring

The invention discloses an LED optical lens. The LED optical lens comprises an LED condenser part, a connection part and a light splitting part. The connection part is arranged between the LED condenser part and the light splitting part. The LED condenser part and the light splitting part are connected together through the connection part. The LED condenser part is composed of a TIR lens. The light splitting part is of a central cone core structure. The contour of the light splitting part is a stepped rotary body. The connection part is a cylinder. By means of the condensation collimation property and the optical total-reflection principle of the TIR lens, the LED optical lens which can generate a uniform visual effect and is composed of a plurality of concentric rings is provided for design of an automobile tail light. Besides, on the basis of the LED optical lens, the number of some scattering materials is increased or the number of other optical lenses is increased, and lamps of various shapes and visual effects can be derived.

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

Neck fixing device for emergency department

The invention discloses a neck fixing device for the emergency department, and belongs to the technical field of emergency equipment. The fixing device comprises a first fixing part located on the back side of the human body and a second fixing part located on the front side of the human body, wherein the first fixing part and the second fixing part are detachably connected through a connecting piece, the first fixing part comprises an outer shell, and the inner side wall of the first fixing part is a U-shaped cavity used for containing the neck; and a fixing mechanism comprises a lamp panel which is arranged above the outer shell and matched with the U-shaped cavity, a liquid storage bag is arranged above the lamp panel, a photoinduced solid-liquid conversion high polymer material is stored in the liquid storage bag, a plurality of ultraviolet lamps are arranged on the lamp panel, and each ultraviolet lamp is electrically connected with a power supply through a control switch. According to the fixing device, a fixing mold completely matched with the neck curve of a patient can be formed according to the individual characteristics of the patient, the fixing effect is kept through a semiconductor refrigeration layer, cold compress is conducted on the affected part, conversion from a solid state to a liquid state is achieved through heat generated by the semiconductor refrigeration layer, and separation of the neck and the neck fixing device is achieved.

Owner:彭州市人民医院

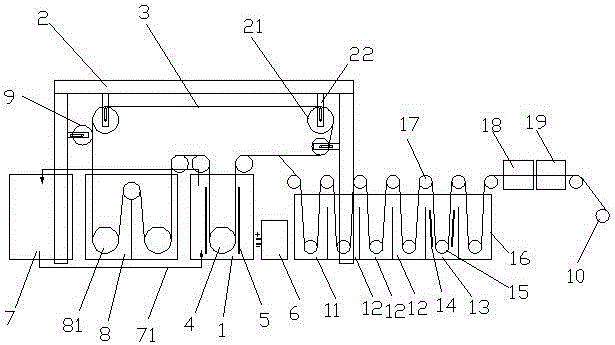

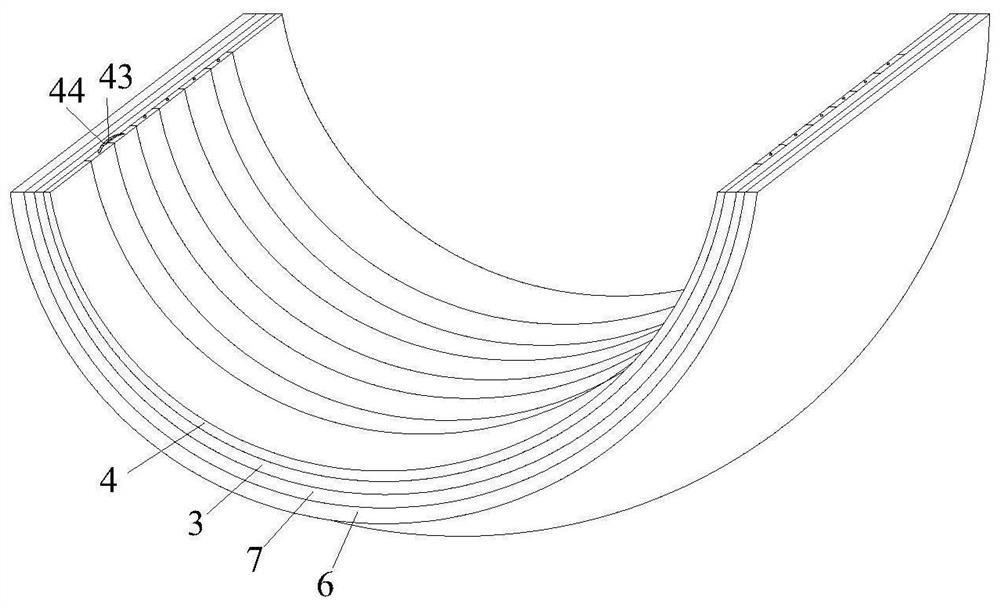

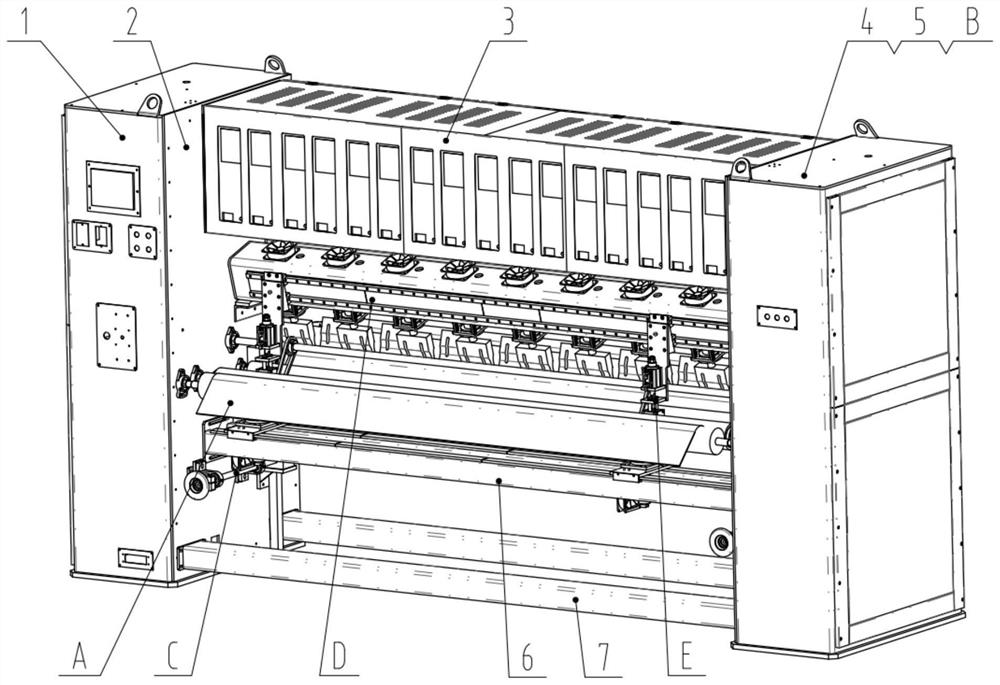

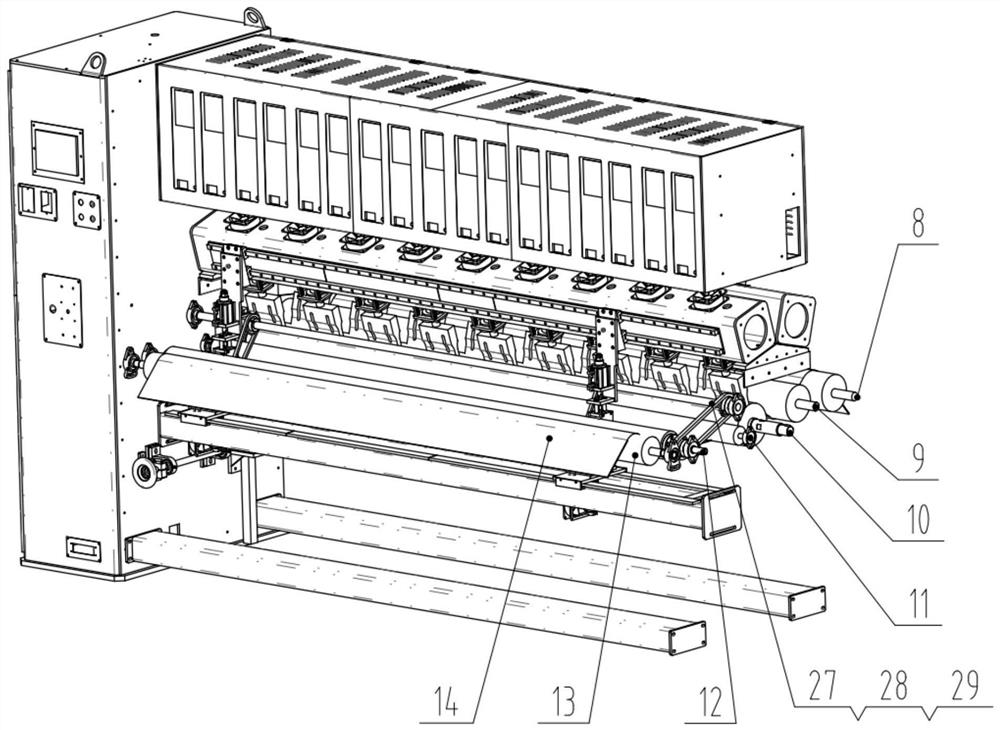

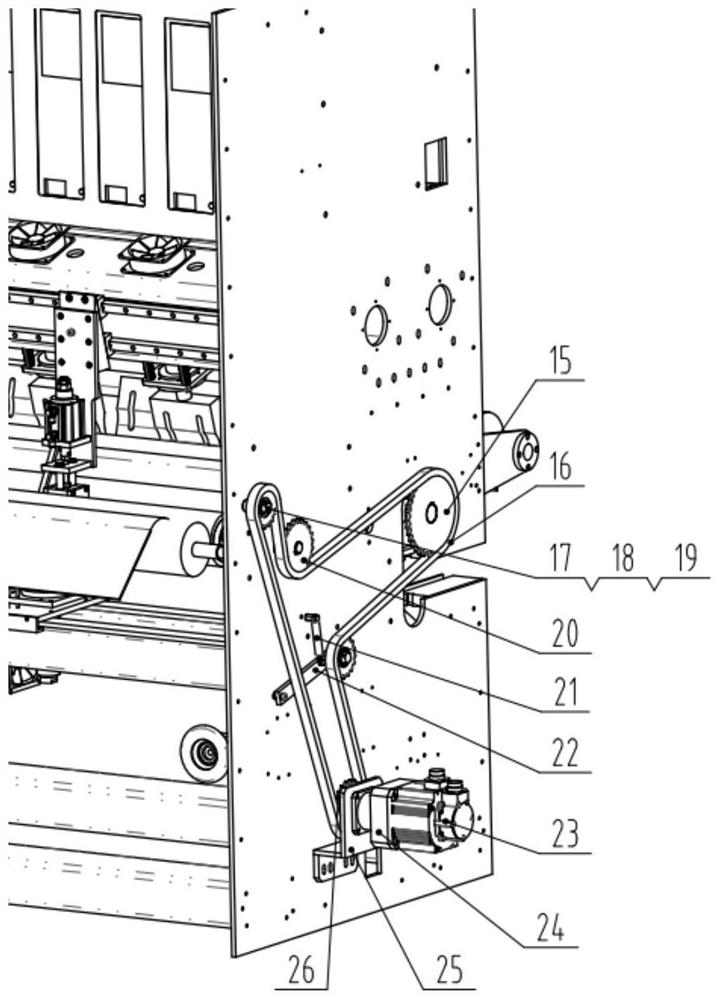

Ultrasonic quilting machine

PendingCN114603866AAchieve widthFulfill usage requirementsPattern makingSevering textilesUltrasonic weldingEngineering

The invention discloses an ultrasonic quilting main machine which comprises a left side box body, a left side plate, a generator support, a right side plate, a right side box body, an edge cutting ultrasonic fixed sliding rail, a fixed lower beam, a cloth trend, a transmission part, a flower roller adjusting part, an ultrasonic part, an edge cutting part and a centrifugal fan. Cloth penetrates in from the upper portion of the first scutching roller from the rear portion from bottom to top, passes through the lower portion of the second scutching roller, the upper portion of the ultrasonic embossing roller, the lower portion of the cloth passing roller, the position between the edge cutting embossing wheel and the second ultrasonic welding head and the position below the first cloth outlet rubber coating roller, and finally penetrates out from the position between the first cloth outlet rubber coating roller and the second cloth outlet rubber coating roller. According to the invention, the use requirement of customers on the edge-cutting welding spots of the cloth finished products is met, and the widths of different cloth finished products are realized by adjusting the position of the edge-cutting part on the guide rail sliding block and the position of the ultrasonic mounting plate II on the edge-cutting ultrasonic fixed sliding rail; and the replacement of the ultrasonic embossing roller is realized by virtue of an auxiliary part, namely the embossing roller replacement support, so that the requirements of different patterns are met.

Owner:上工富怡智能制造(天津)有限公司

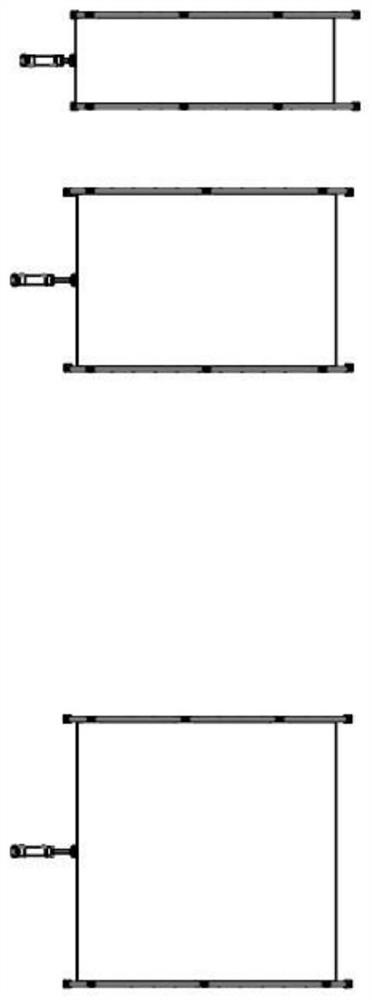

Platform structure for assembling and dissembling carrying vehicle

PendingCN107915069ARealize functionAchieve widthLoading/unloadingMarine engineeringStructural engineering

The invention discloses a platform structure for loading and unloading a carrying vehicle. The platform structure comprises load-bearing supporting leg oil cylinders, a plurality of folding plates which are sequentially arranged in parallel and a plurality of lap plates, wherein every two adjacent folding plates are connected through a hinge mechanism, and folding and unfolding functions of the folding plates are realized through a turnover connector and two telescopic oil cylinders; the connecting end of each folding plate is connected with the corresponding lap plate capable of turning over,and a space used for mounting the lap plate is reserved in the top of the connecting end of each folding plate; each lap plate is used for compensating a seam during butt-joint of the platform and arailway flatcar; each lap plate and each folding plate are connected through a folding mechanism, and the lap angle and self-locking of each lap plate are realized through the corresponding folding mechanism and the corresponding oil cylinder; and the load-bearing supporting leg oil cylinders are mounted on the bottom surfaces of the folding plates, and stretching-out and drawing-back of the load-bearing supporting leg oil cylinders are completed by pushing-pulling oil cylinders. The platform structure can be used for positively unloading and laterally loading, adopts a folding type structurewhich is relatively wide after being unfolded, does not depend on terrain, is flexible to unload, and is safe and reliable.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

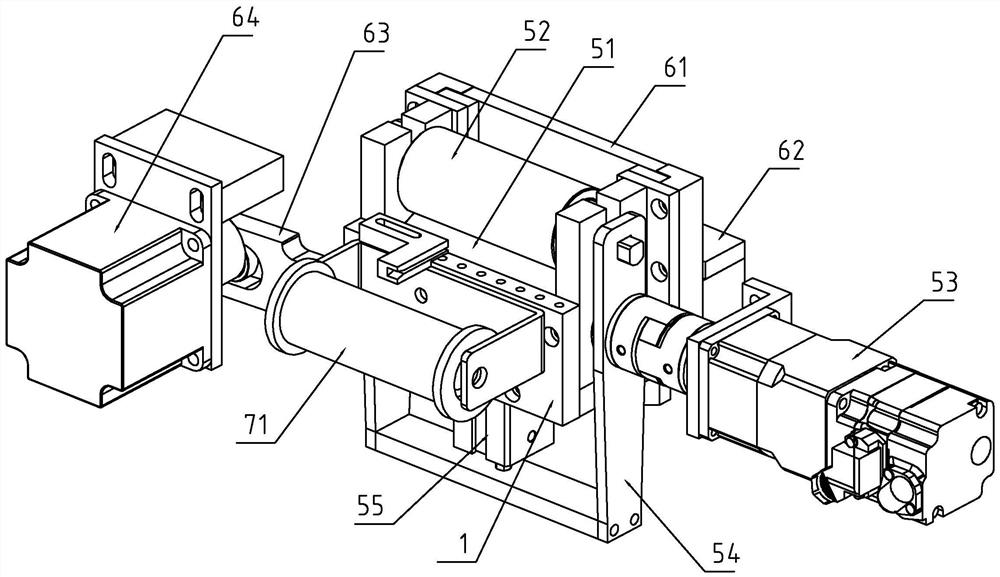

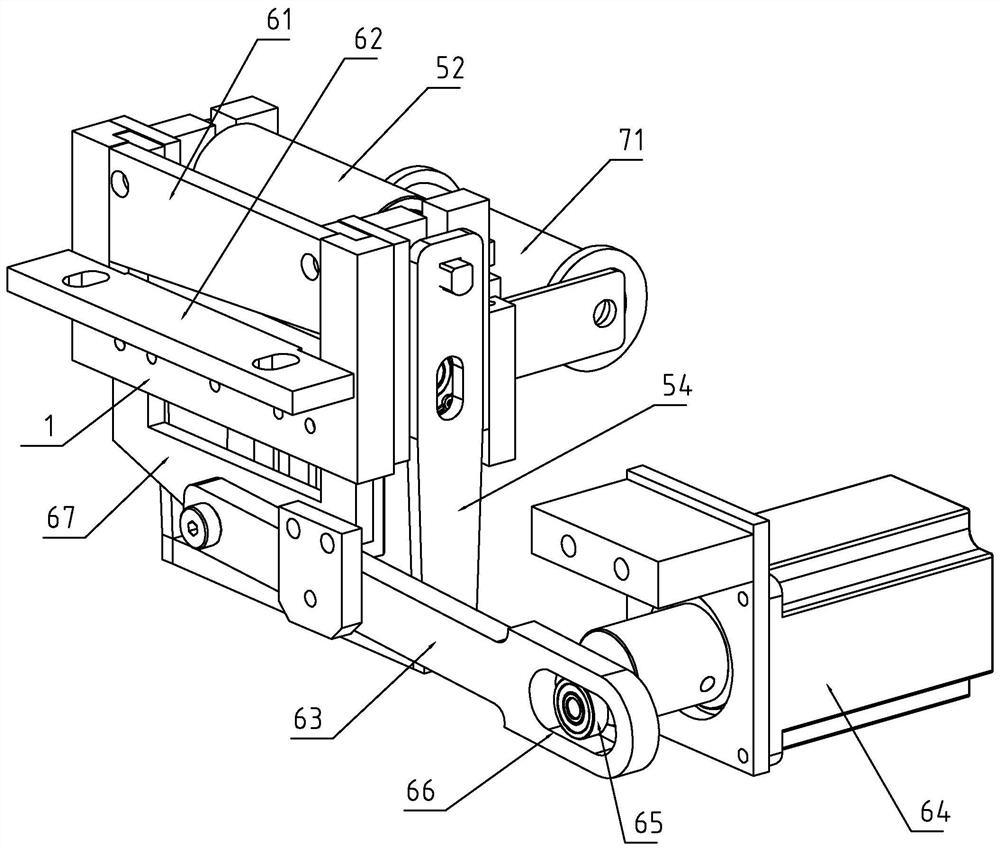

Soft center strip feeding device for covering machine

The invention discloses a soft center strip feeding device for a covering machine. The soft center strip feeding device is located at the feeding end of a paperboard feeding station. According to the technical scheme, the soft center strip feeding device is characterized by comprising a covering machine rack, a material coiling disc, a traction assembly, cutting assemblies, a clamping and conveying assembly and a cutting assembly, wherein the material coiling disc is arranged on the covering machine rack and used for coiling elongated soft center strips, the traction assembly is arranged on the covering machine rack and used for pulling the soft center strips, the cutting assemblies are located between the material coiling disc and the traction assembly and used for cutting the soft center strips, the clamping and conveying assembly is located at the discharging end of the traction assembly and used for pushing the soft center strips to the paperboard feeding station, and the cutting assembly is located at the discharging end of the clamping and conveying assembly and used for cutting off the soft center strips; and at least one set of cutting assembly is arranged and located on the side edges of the soft center strips in the width direction, each cutting assembly comprises two cutting circular knives, the two cutting circular knives are located on the upper side and the lower side of each soft center strip correspondingly, and annular cutting edges are arranged on the cutting circular knives. By means of the feeding device, automatic cutting and discharging of the soft center strips can be achieved.

Owner:浙江容健科技有限公司

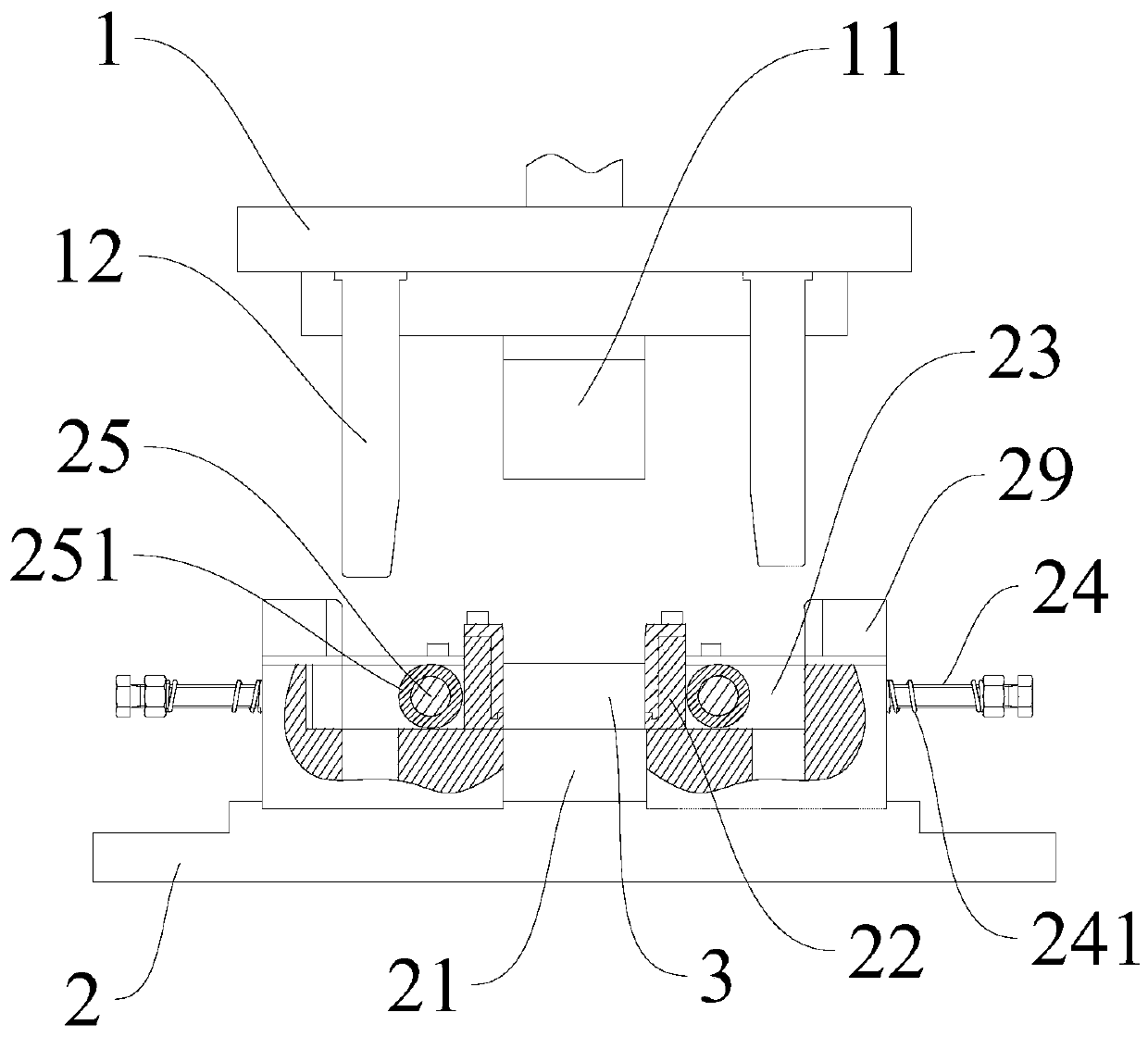

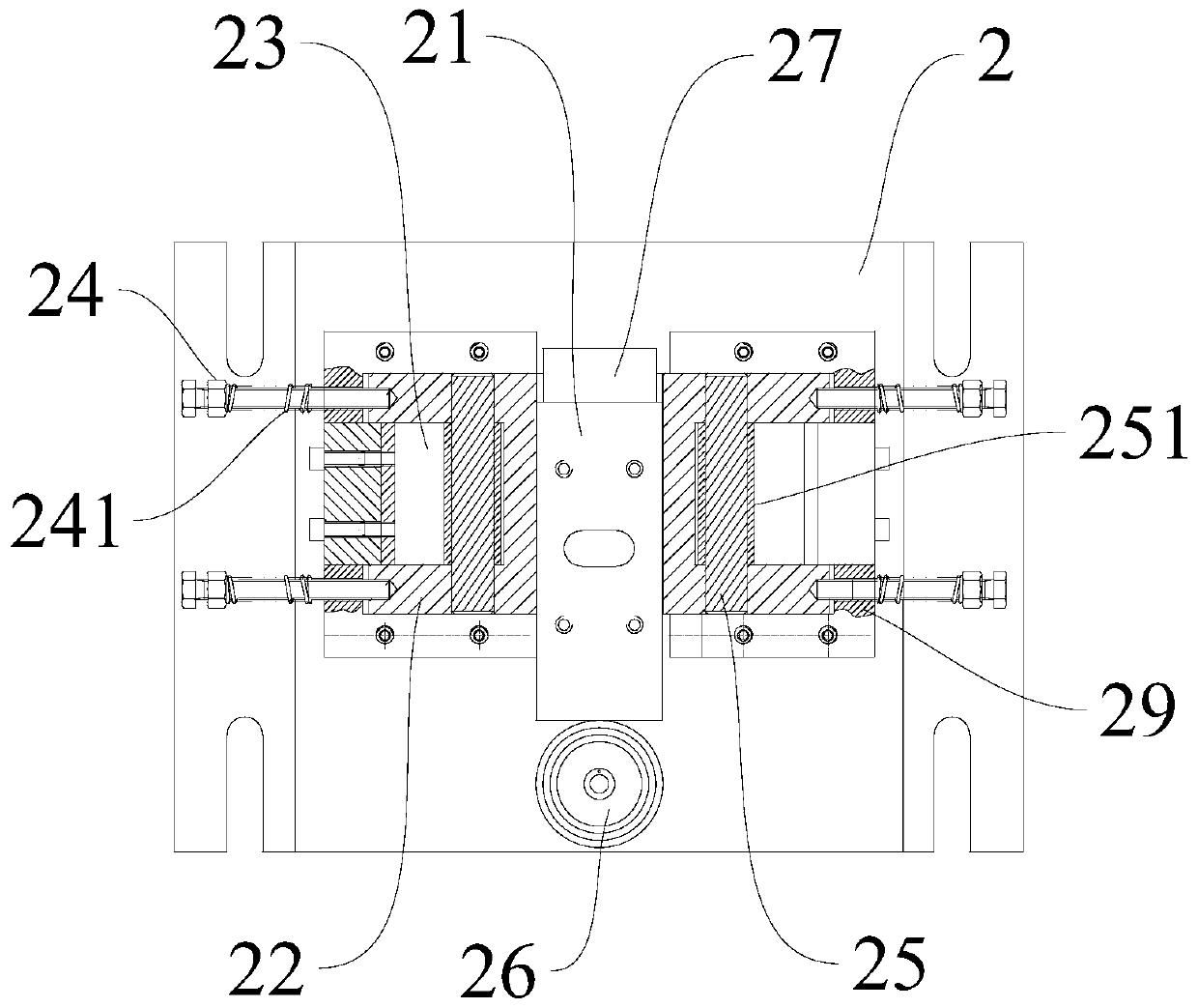

mold

ActiveCN109821981BAchieve widthAchieve moldingShaping toolsMetal-working feeding devicesMechanical engineeringMachining time

The invention discloses a die for machining a workpiece. An upper template and a lower template are included and are oppositely provided with an upper die forming block and a lower die forming block correspondingly. The lower die forming block is used for containing the workpiece, the parts, located on the two sides of the lower die forming block, of the lower template are provided with transverseextrusion blocks, and the transverse extrusion blocks are provided with guiding grooves. The upper template is provided with wedge-shaped blocks corresponding to the guiding grooves. When the wedge-shaped blocks downwards stretch into the guiding grooves to slide, the two transverse extrusion blocks oppositely move. When the upper die forming block conducts downward pressing, the wedge-shaped blocks can move along with the upper die forming block, meanwhile, the wedge-shaped blocks can push the transverse extrusion blocks to move, the die can achieve workpiece width finishing and forming simultaneously or sequentially, additional adoption of other dies is not needed, the machining time is shortened, and the production cost is reduced.

Owner:田沃土

Broadband Transition Structure Between Grounded Coplanar Waveguide and Stripline with Curved Grounding Electrode

A broadband transition structure between a grounded coplanar waveguide and a stripline with a curved ground electrode, comprising: stacked two-layer silicon wafers, uniformly grounded coplanar waveguide units, gradient grounded coplanar waveguide units, and striplines arranged in sequence The unit and the microstrip line unit, the first strip line, the through-silicon via unit and the second strip line connected sequentially inside the gradient ground coplanar waveguide unit and the strip line unit. The invention adopts the grounding electrode whose edge changes in a curve with the width of the equivalent trapezoidal conduction strip, so as to ensure that the characteristic impedance of the gradually changing grounded coplanar waveguide is always the standard impedance; the width and length of the stripline are optimized, so that the equivalent inductance of the stripline and the TSV is equal to the The gap equivalent capacitances are balanced with each other to achieve broadband impedance matching. The device does not need to open a hole on the ground plane, does not increase the complexity of the process, can achieve a large working bandwidth, and meets the requirements of the three-dimensional interconnection network in the silicon-based three-dimensional integrated circuit for broadband and low-loss transmission of radio frequency millimeter wave signals.

Owner:SHANGHAI JIAOTONG UNIV

A combined production line for spunlace nonwovens

ActiveCN111707080BReduce labor intensityAchieve widthDrying gas arrangementsSevering textilesEngineeringNonwoven fabric

Owner:射阳县宏瑞纺织机械制造有限公司

Composite material manufacturing method based on three-dimensional micro-nano structured arrangement of particles at the micro-nano scale

ActiveCN109467046BRealize three-dimensional patterned arrangementRealize directional and localized controlSpecific nanostructure formationNanostructure manipulationNanoparticleThree dimensional shape

The invention relates to a method for manufacturing a composite material based on nano-particle three-dimensional micro-nano structured arrangement, which comprises the following steps of: placing micro-nano particles in mother liquor to obtain a solution containing micro particles; placing part of the solution in a container for leveling, applying a first structured field to the solution in a container, and controlling the particles in the solution to achieve controllable patterning arrangement of the particles in the solution; solidifying and molding the solution in the container, moving thecontainer downwards, supplementing the solution containing the micro particles in the container, changing structural field parameters to achieve the longitudinal controllable arrangement of the particles in the solution, and adopting different structural fields to achieve different patterning arrangements of the particles in the solution containing the micro particles; changing a first structuralfield into a second structural field so that the particles are arranged into corresponding shapes; repeating until the composite material with three-dimensional micro-nano structured arrangement of functional nanoparticles is obtained; the method has the advantages of directional localized adjustment, high efficiency, capability of achieving the forming of any three-dimensional shape structure and the like.

Owner:XI AN JIAOTONG UNIV

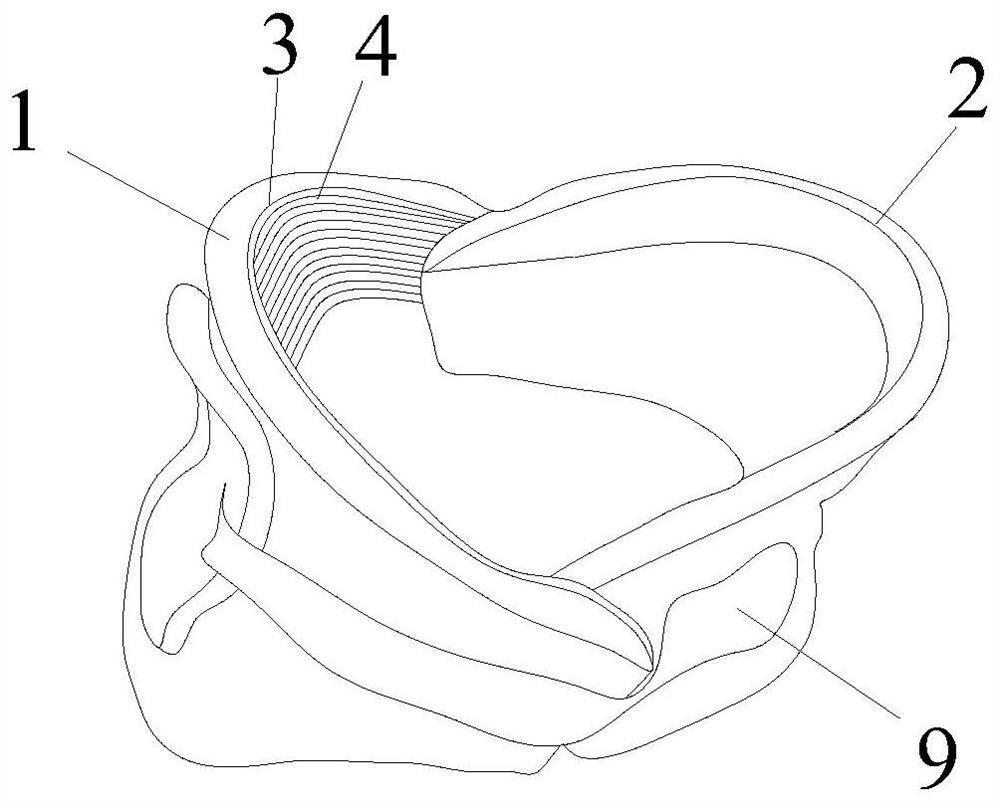

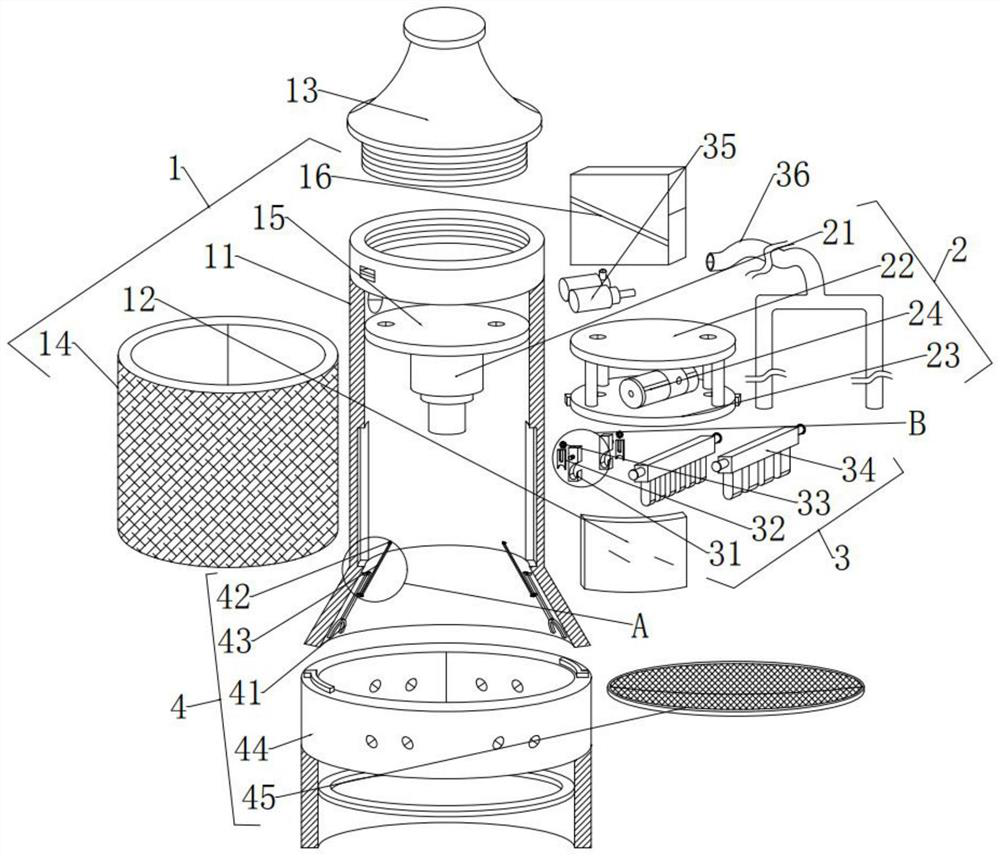

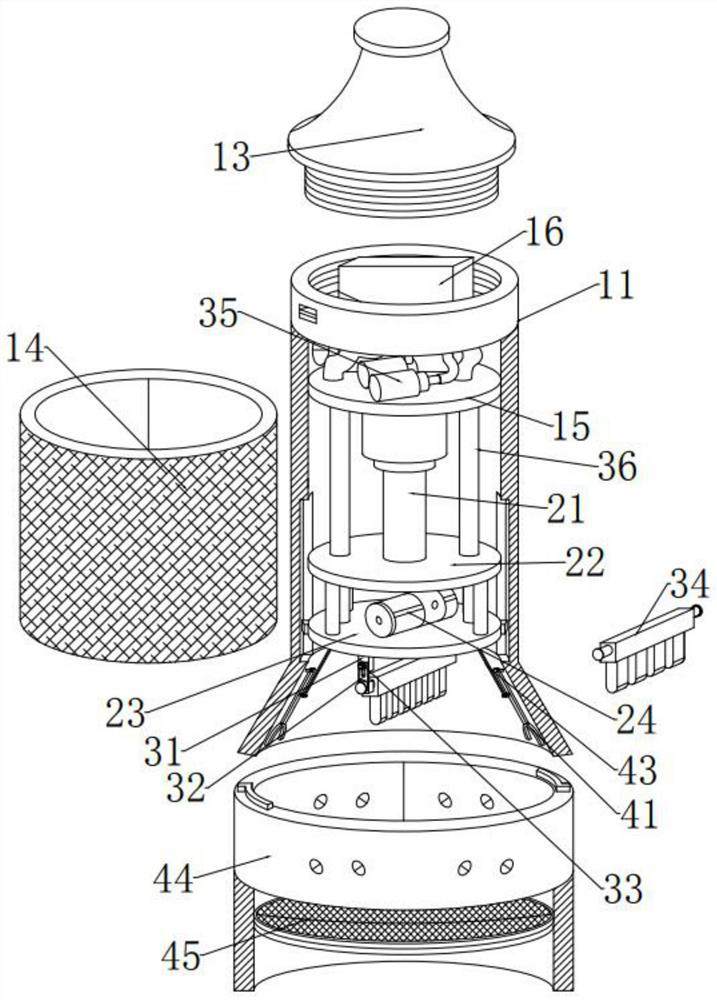

Scraping therapy device for traditional Chinese medicine acupuncture and massage department and use method of scraping therapy device

InactiveCN113397937ASimple structureLow costDevices for heating/cooling reflex pointsPneumatic massageBiomedical engineeringTraditional Chinese medicine

The invention discloses a scraping therapy device for the traditional Chinese medicine acupuncture and massage department. The scraping therapy device comprises a main body structure, an exchange structure, a scraping therapy structure and a moxibustion structure. The exchange structure is fixedly arranged in the main body structure, the scraping therapy structure is fixedly arranged on the exchange structure and located in the main body structure, and the moxibustion structure is detachably arranged on the main body structure and located below the scraping therapy structure. The invention relates to the technical field of massage equipment. According to the scraping therapy device for the traditional Chinese medicine acupuncture and massage department, through force application and driving and control of the main body structure, the scraping therapy device can be adjusted to be used in three modes of scraping therapy, vibration or moxibustion conversion, and the scraping therapy force and the scraping therapy mark width can be realized by replacing a scraping therapy plate and adjusting suction force; the scraping therapy device is simple in overall structure, low in cost, convenient to carry, small in overall size, light, convenient to use by manual force application, multiple in function and capable of achieving the conversion use function.

Owner:崔芳

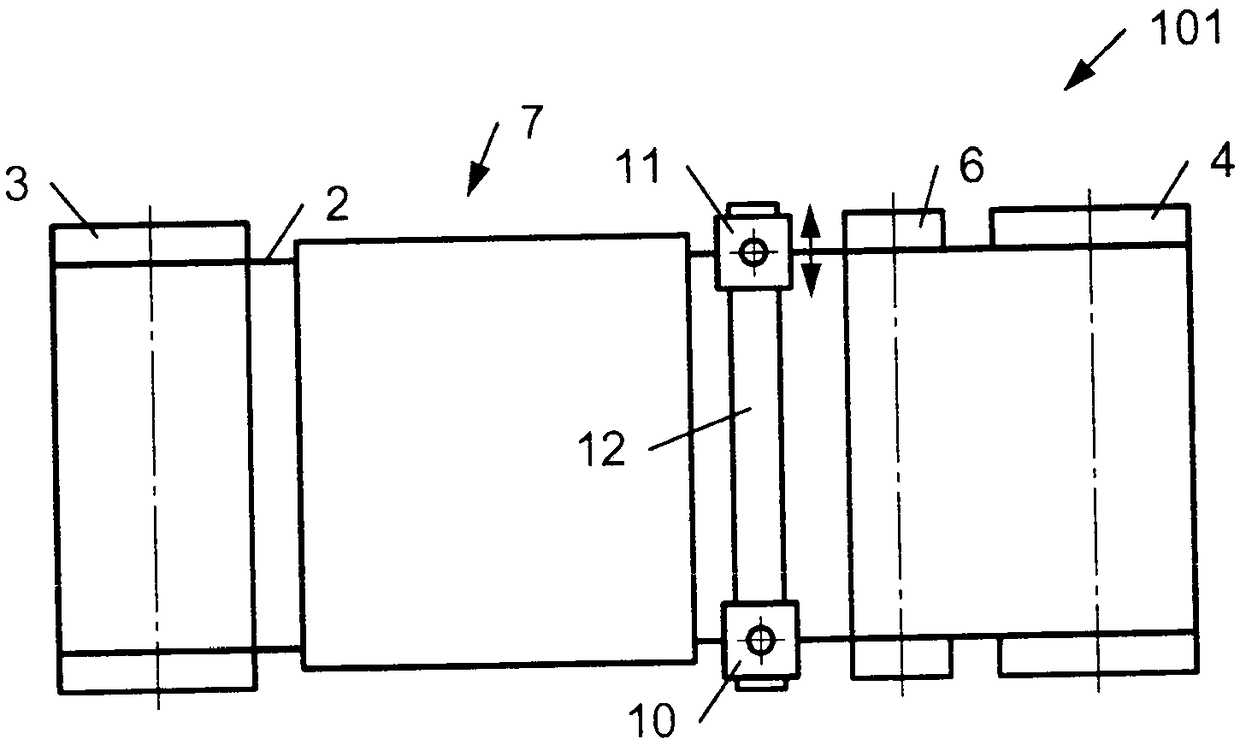

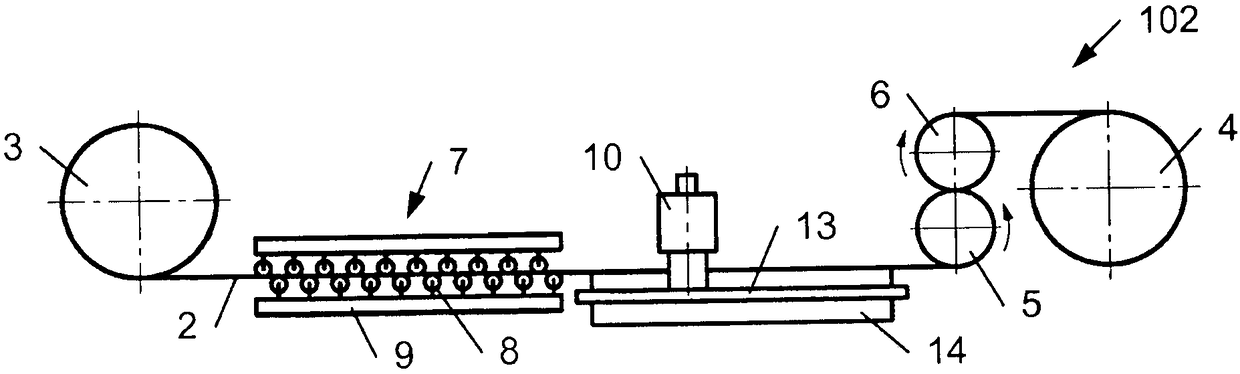

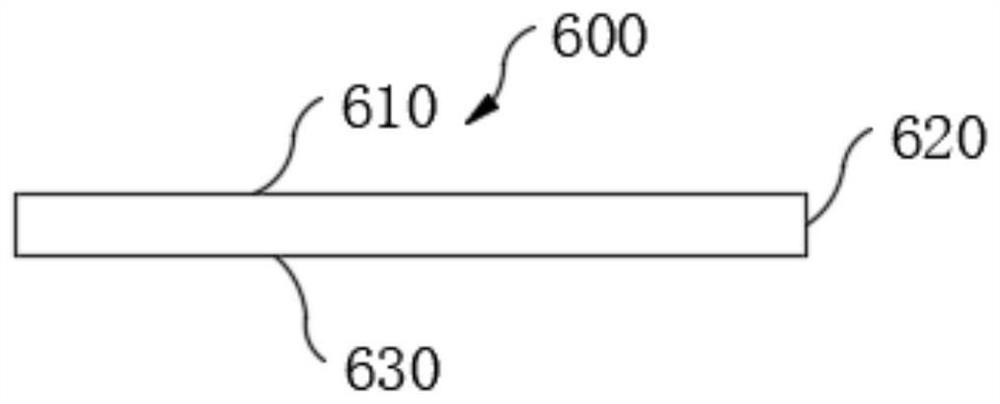

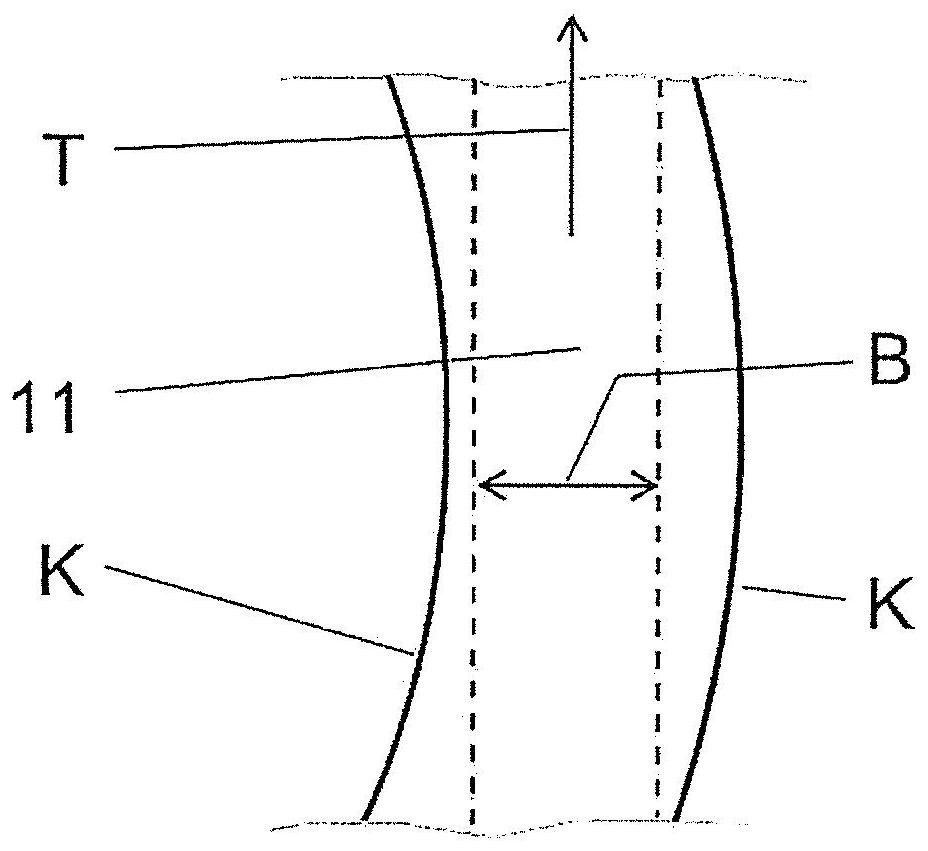

Method and device for producing a metal strip with substantially parallel strip edges

ActiveCN108136468ASave construction spaceEasy to fixShearing machinesMetal rolling arrangementsEngineering

The invention relates to a method for producing a metal strip (2) with substantially parallel strip edges (20, 21), in which the metal strip (2) is edged, in that at least a part of the strip edges (20, 21) of the metal strip (2) is removed. In addition, the metal strip (2) is plastically reshaped during a straightening process. In order to carry out the method, a device (101...106) is provided, which comprises a trimming tool (10, 11) and a drive (3...6, 15...18) for generating a relative movement between the trimming tool (10, 11) and the metal strip (2) in the direction of the longitudinalaxis of the metal strip (2). The device (101...106) also comprises a unit (7, 22...25) for plastic reshaping of the metal strip (2).

Owner:BERNDORF BAND GMBH

Sow feeder with adjustable width passage

InactiveCN102577992ASimple structureEasy, quick and efficient installationAnimal feeding devicesFisheryStructural engineering

The invention relates to automatic sow feeding equipment and technology, in particular to a sow feeder with an adjustable width passage. One door plate is disposed between one upper lateral pipe and a corresponding lower lateral pipe of a passage. The corresponding lateral pipes and one door plate form one lateral wall of the passage. Upper supports extending out of each door plate are disposed at the upper end of the door plate, and lower supports extending out of each door plate are disposed at the lower end of the door plate. Pin positioning sleeves are disposed on each upper support. Lateral pipe positioning pipes are reserved on each lower support. The corresponding upper lateral pipe is fixed to the corresponding door plate through the pin positioning sleeves. The corresponding lower lateral pipe is fixed to the corresponding door plate through the lateral pipe positioning grooves. The sow feeder is quite convenient in use, and the width of the passage of the feeder can be optionally adjusted according to different growth stages of sows so as to allow the sows to easily and smoothly pass the passage. The door plates close two sides of the passage formed by the lateral pipes and the door plates, so that the sows are prevented from staying in the passage to affect feeding.

Owner:CHENGDU TONGWEI AUTOMATION EQUIP

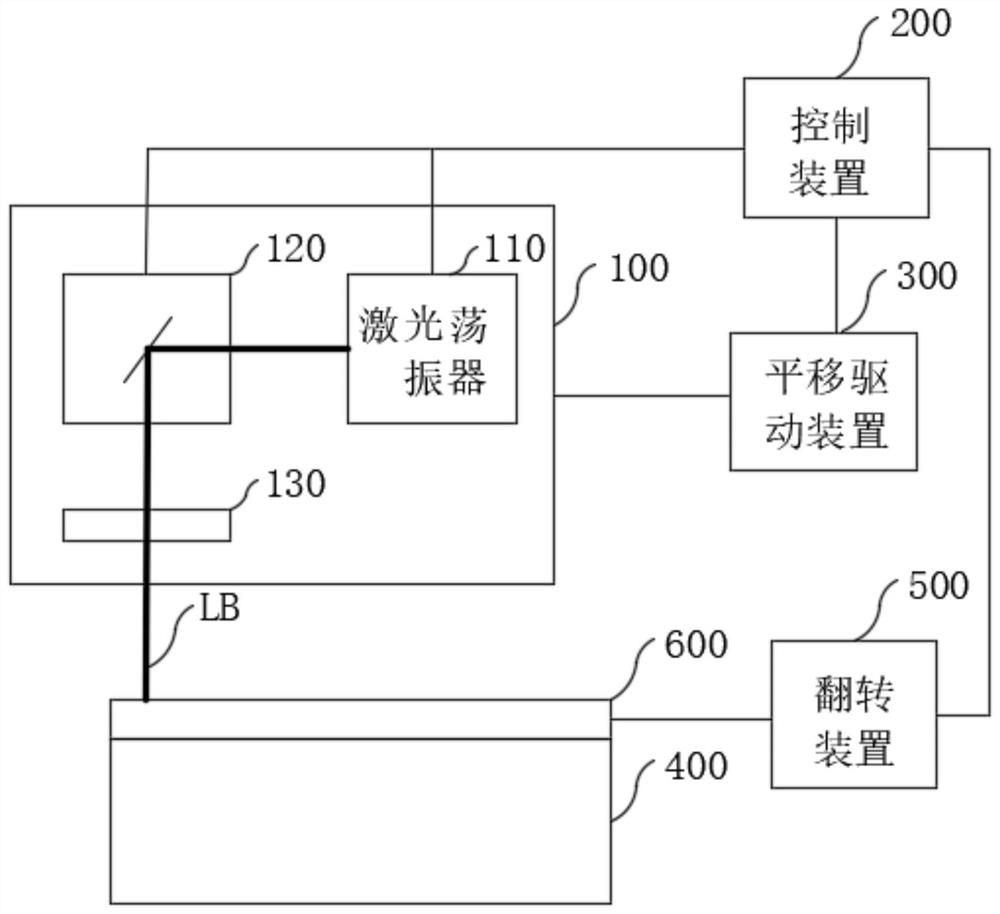

Laser processing system and laser processing method for protective substrate

PendingCN111875246AIncrease productivityAvoid spreadingGlass severing apparatusGlass productionLaser processingGalvanometer

The invention provides a laser processing system and a laser processing method for a protective substrate. The laser processing system for the protective substrate comprises: a substrate bearing table; a laser generating device which comprises a laser oscillator, a galvanometer assembly and a light gathering element; a translation driving device which is connected with the laser generating device;and a control device that is connected with the laser generation device and the translation driving device, wherein the control device drives the laser generation device to move by utilizing the translation driving device, so that the laser beam moves along the edge of the protective substrate to reinforce the side surface of the protective substrate. By means of the method, the production efficiency of the protective substrate made of the tempered glass material can be remarkably improved, cracks are prevented from spreading into the protective substrate, and the quality of a finally-formedproduct can be improved.

Owner:江苏亚威艾欧斯激光科技有限公司

A truck loading position and attitude adjustment device and adjustment method thereof

ActiveCN110329806BAchieve widthRealize regulationLoading/unloadingHydraulic cylinderStructural engineering

The invention relates to a truck loading pose adjusting device and an adjusting method thereof, and belongs to the technical field of truck pose adjustment. The adjusting device comprises movable platforms, steel wheels and a hydraulic cylinder, wherein the steel wheels are positioned below the two sides of the movable platforms, and the hydraulic cylinder is used for driving the movable platforms; three sets of the movable platforms are arranged, the three sets of movable platforms are located in three pits of the ground respectively, and the distances between the three sets of movable platforms correspond to the intervals between three sets of wheels of the truck respectively; guide rails are arranged below the steel wheels in the pits, the steel wheels slides along the guide rails to achieve the movement of the movable platforms in the width direction, so that the problems that an existing automatic loading system is difficult to accurately place the truck on the loading position and truck position and angle adjustment are encountered during loading are solved, the automation degree of the automatic loading system is improved, the loading efficiency is improved, and the labor cost is saved.

Owner:SHANDONG UNIV OF SCI & TECH

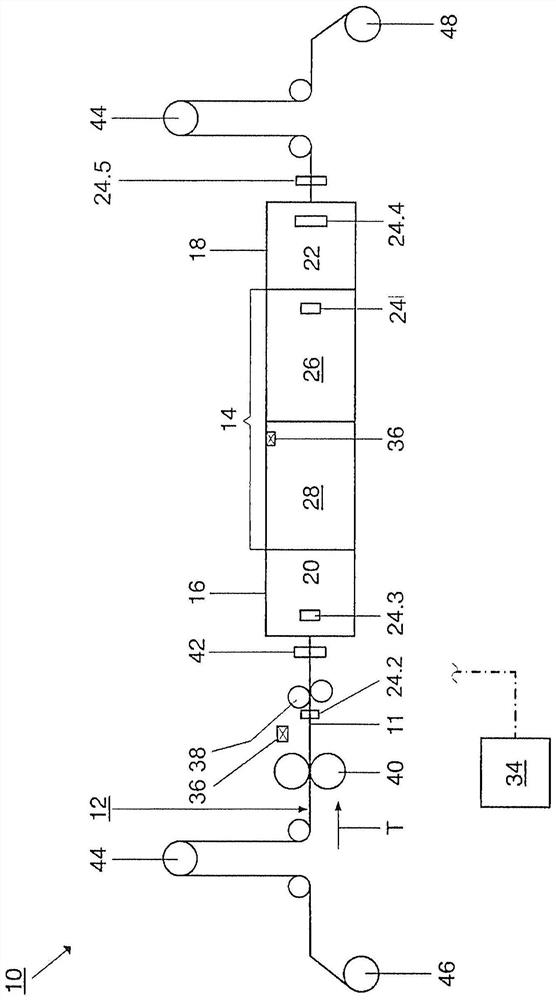

Vacuum-coating system and method for coating a strip-type material

ActiveCN112203961AConstant widthAchieve widthVacuum evaporation coatingSputtering coatingCoating systemMechanical engineering

The invention relates to a method and a vacuum-coating system (10) for coating a strip-type material (11), in particular made of metal. For this purpose, the strip-type material (11) is moved along aconveying section (12) in a transport direction (T) and is vacuum coated inside a coating chamber (14) in which a vacuum is applied. When viewed in the transport direction (T) of the strip-type material (11), at least one set of trimming shears (38) is arranged upstream of the coating chamber (14), with which the strip-type material (11) is trimmed on at least one strip edge, preferably on both strip edges, in order to create a constant width for the strip-type material (11) over its longitudinal extension.

Owner:SMS GRP GMBH

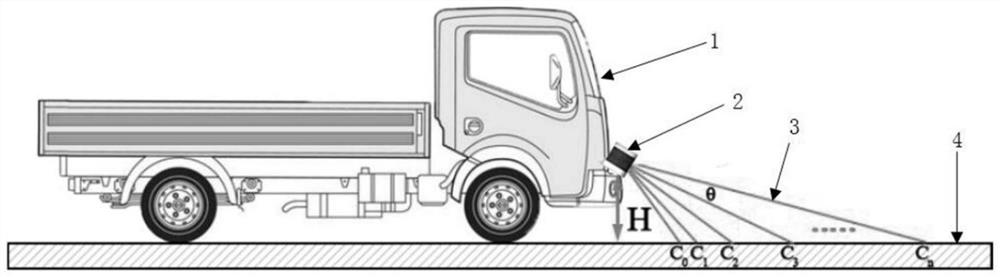

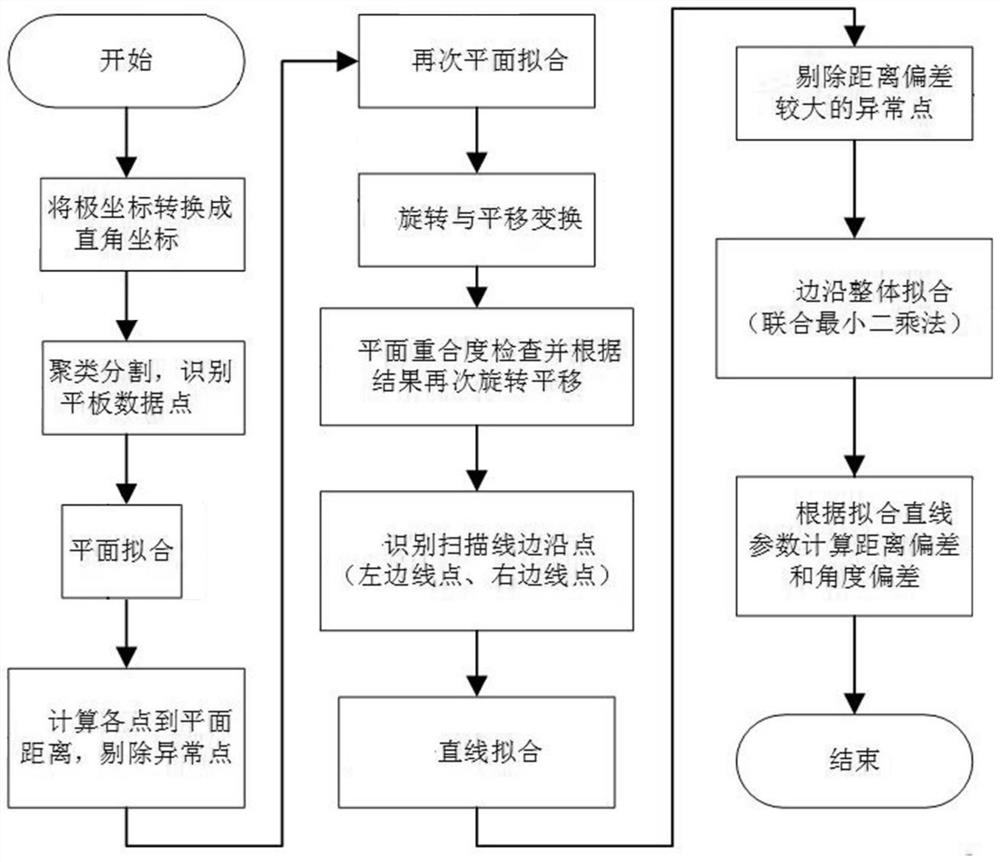

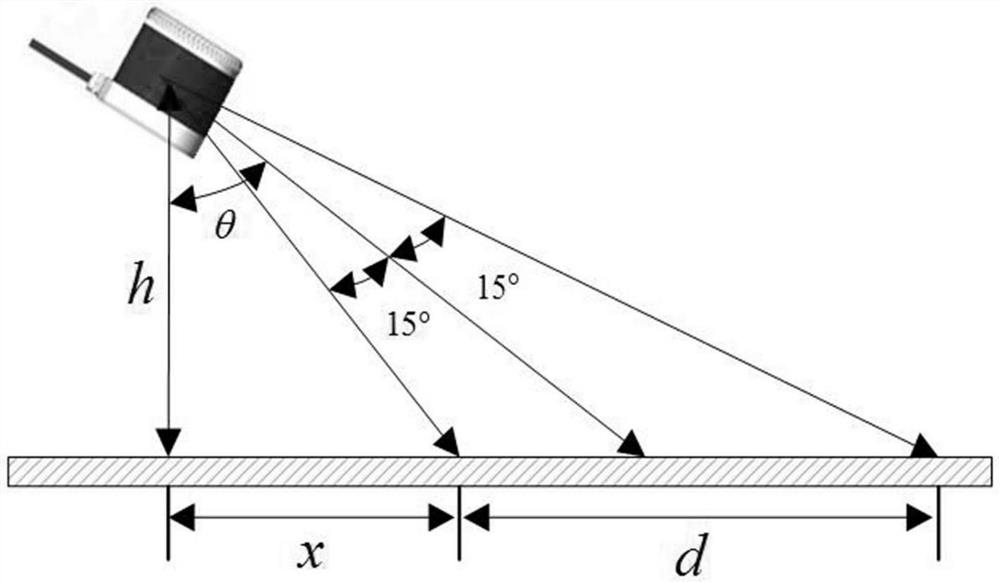

Equipment automatic loading deviation identification method and system based on three-dimensional laser radar

The invention discloses an equipment automatic loading deviation identification method and system based on a three-dimensional laser radar, and belongs to the technical field of equipment loading deviation control. The method comprises the steps of scanning an area where a railway slab is located, obtaining original point cloud data and performing preprocessing; clustering segmentation is carried out on the preprocessed original point cloud data, and railway slab data points are identified; performing plane fitting on the railway slab data points to obtain a three-dimensional fitting plane; converting the three-dimensional fitting plane into a two-dimensional fitting plane through rotation and translation transformation; and carrying out straight line fitting on the edge points on the two sides of the two-dimensional fitting plane at the same time to obtain straight line parameters, and then calculating to obtain the automatic loading deviation of the equipment. The method can automatically identify the width of the railway slab and the distance deviation and angle deviation of equipment relative to the center line of the railway slab, and has the characteristics of simple identification, high intelligent degree, strong adaptability and the like.

Owner:ARMY ENG UNIV OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com