Three-dimensional real-time gluing detection method and device

A technology of glue coating detection and real-time detection, applied in measuring devices, optical devices, instruments, etc., can solve problems such as inability to detect, and achieve the effect of comprehensive detection content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

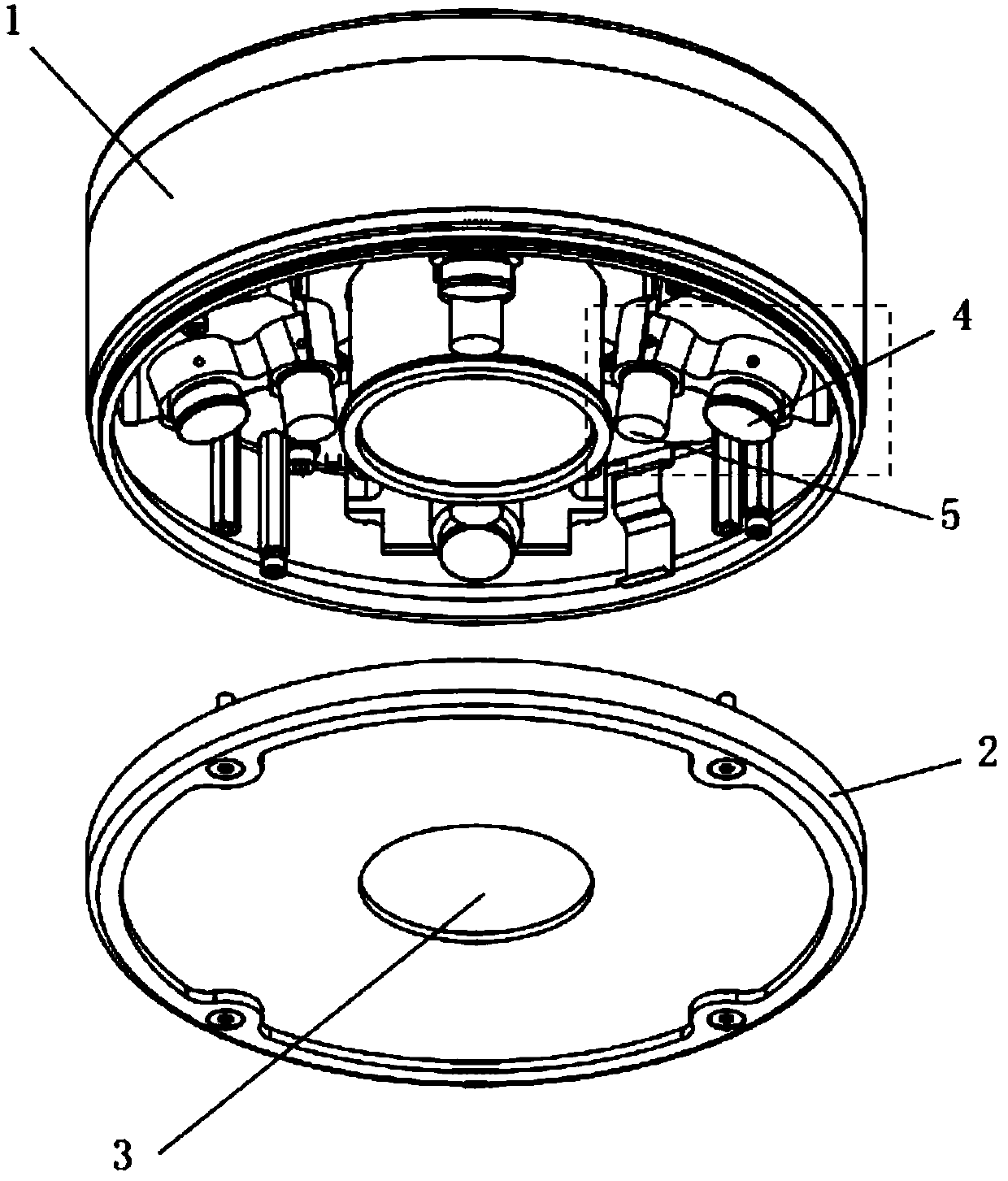

[0030] In order to better understand the present invention, the following examples are given and described in detail in conjunction with the accompanying drawings:

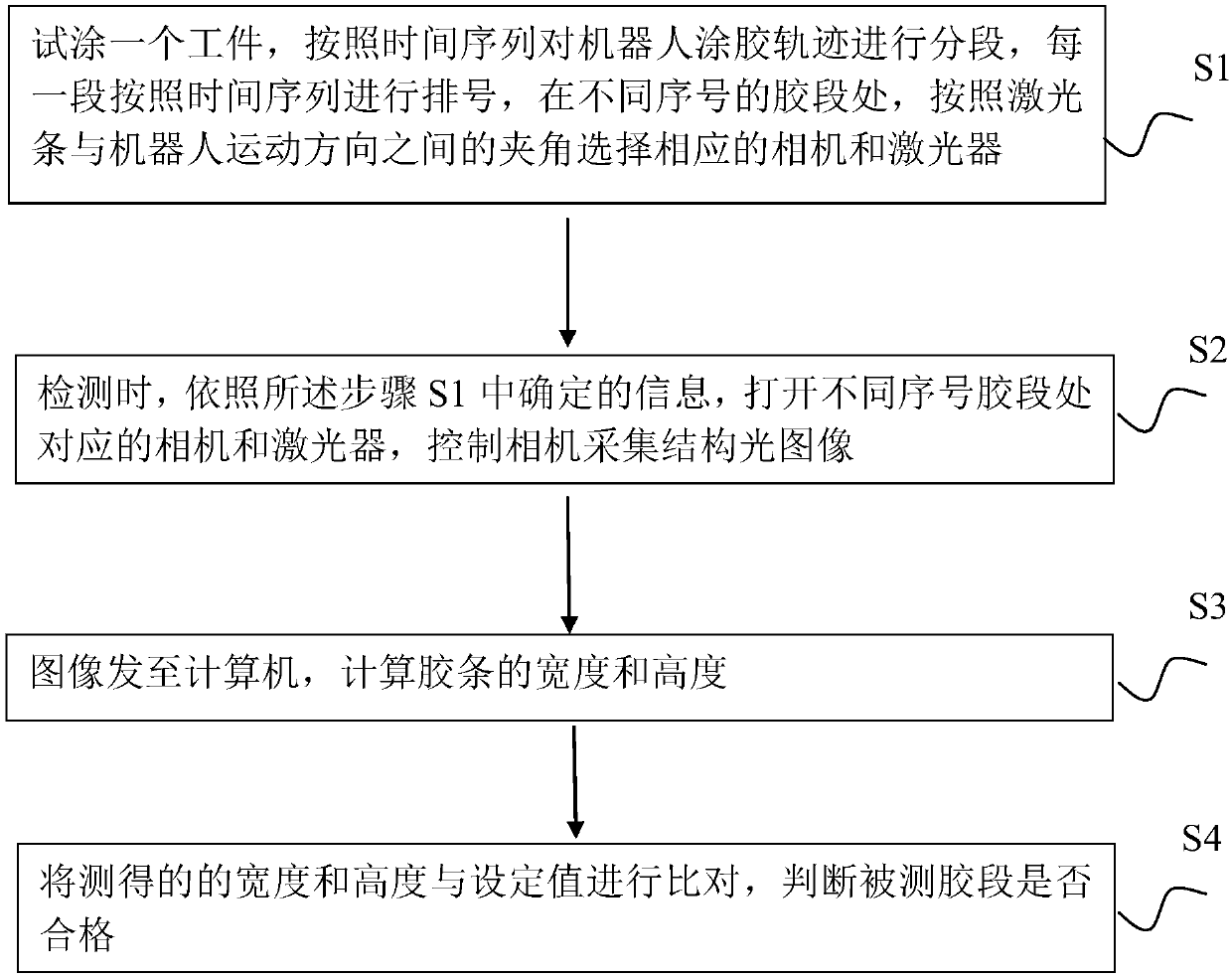

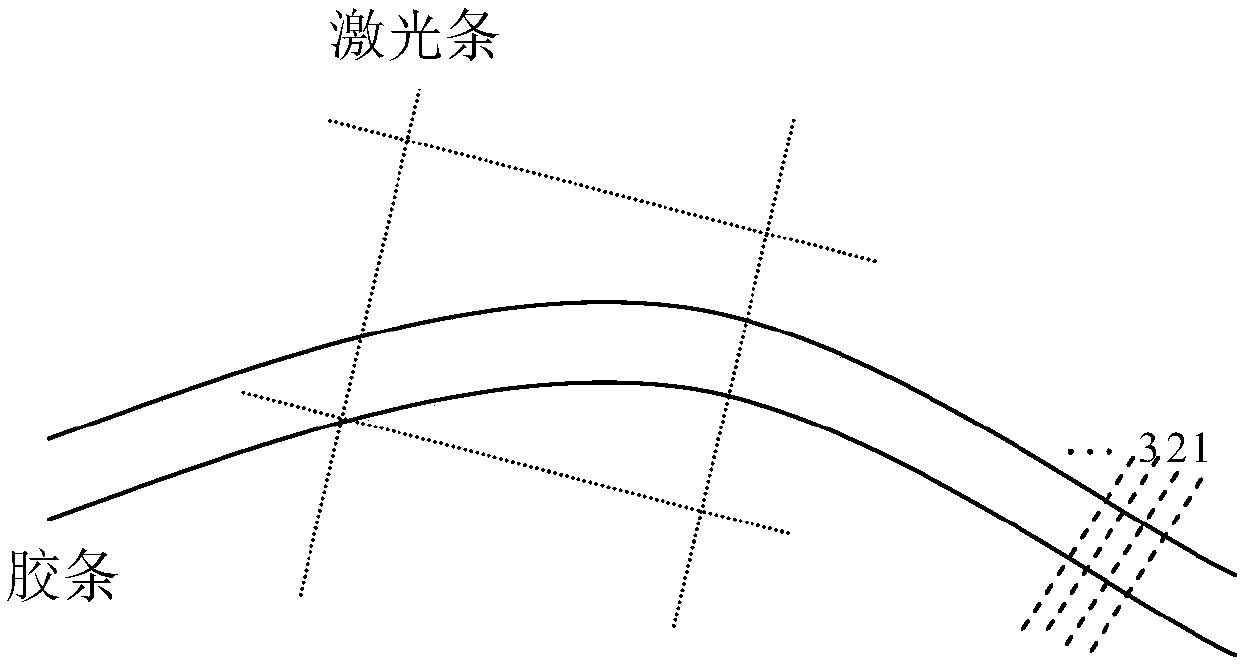

[0031] A three-dimensional real-time glue detection method and device. During the first detection, the teaching process is carried out first, and the glued strip is subdivided and quantified into different glue strip segments, and sorted, and the selected glue segments with different serial numbers are correspondingly opened The camera and laser, and then use the three-dimensional measurement principle of the structured light method to obtain the three-dimensional data of the structured light image of the rubber strip to be tested, so as to analyze the width, height and continuity of the rubber strip to be tested, and judge whether it is qualified or not.

[0032] Specifically as Figure 1-2 As shown, the three-dimensional real-time gluing detection method includes the following steps:

[0033] S1: Try to coat a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com